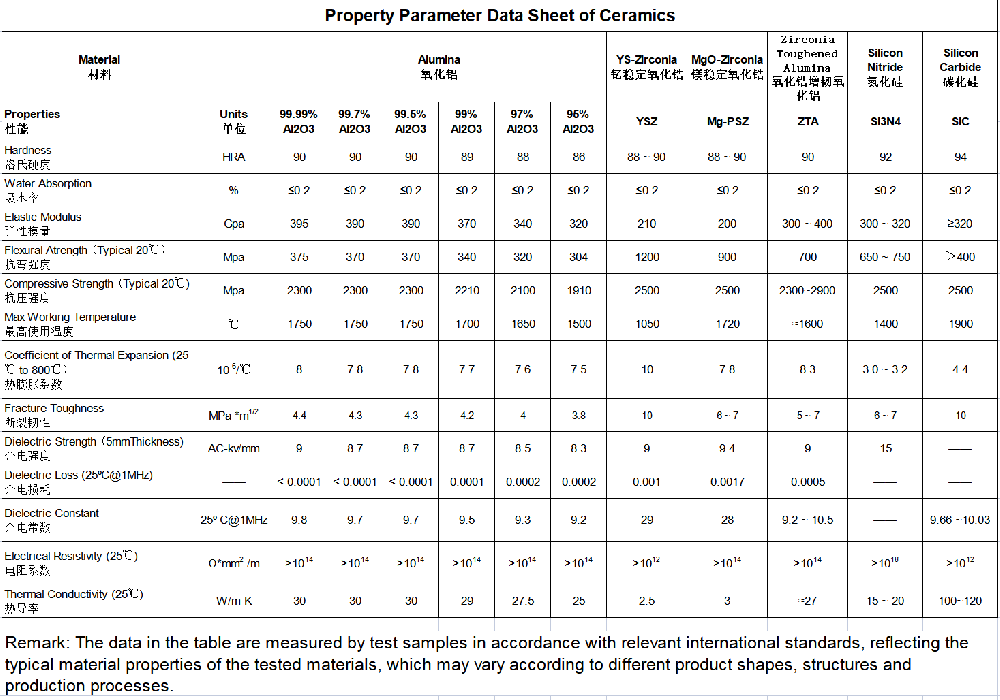

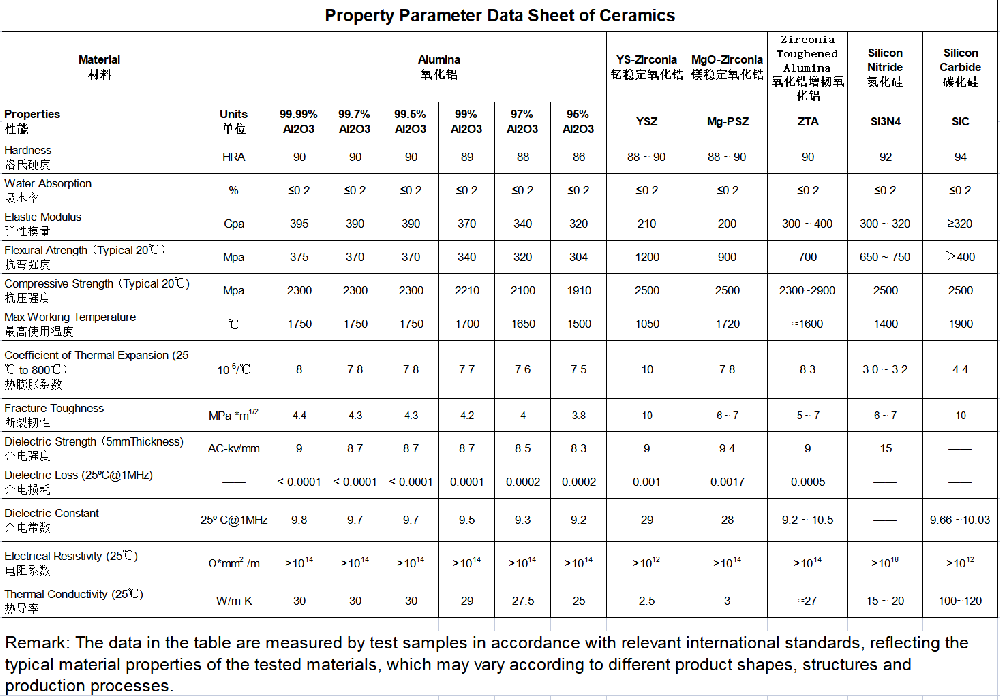

Ceramic Patameters

Here are our commonly used ceramic parameters. Usually each industry according to the actual parameter requirements are not the same. Here is part of our ceramic parameters display, the specific application of ceramic parameters please contact us.

Parameter characteristics of structural ceramics

1, Structural ceramics is to play its mechanical, thermal, chemical and other properties of a new class of ceramics, which can be in many harsh working environment "service", so it has become the key to the realization of many emerging science and technology.

2, The vast majority of structural ceramics have strong load bearing capacity, erosion resistance, acid and alkali resistance, low creep rate, low density and other excellent properties, often can be applied to a variety of structural components.

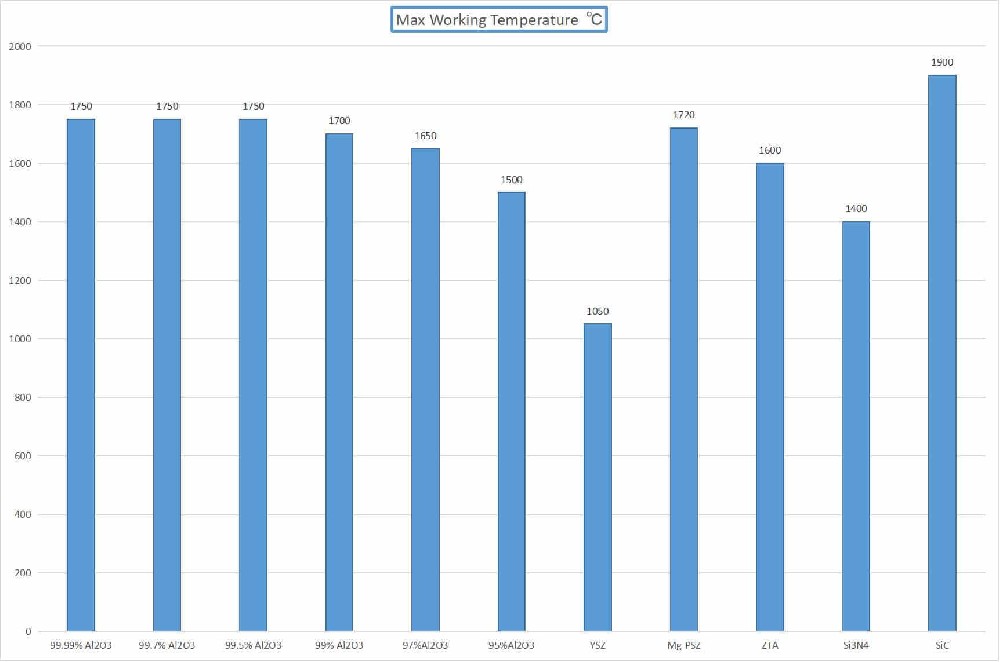

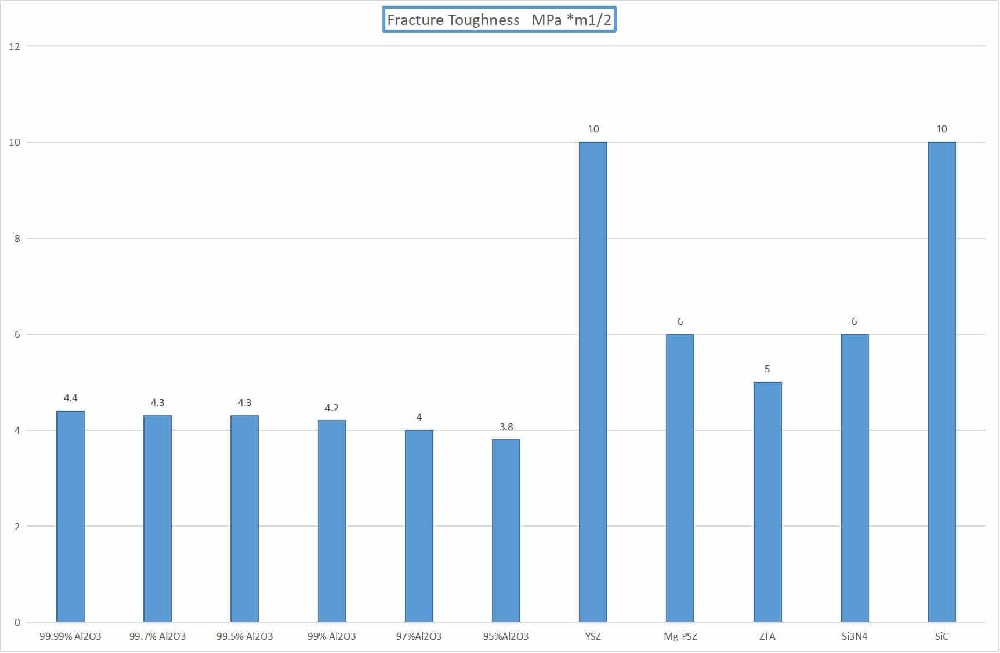

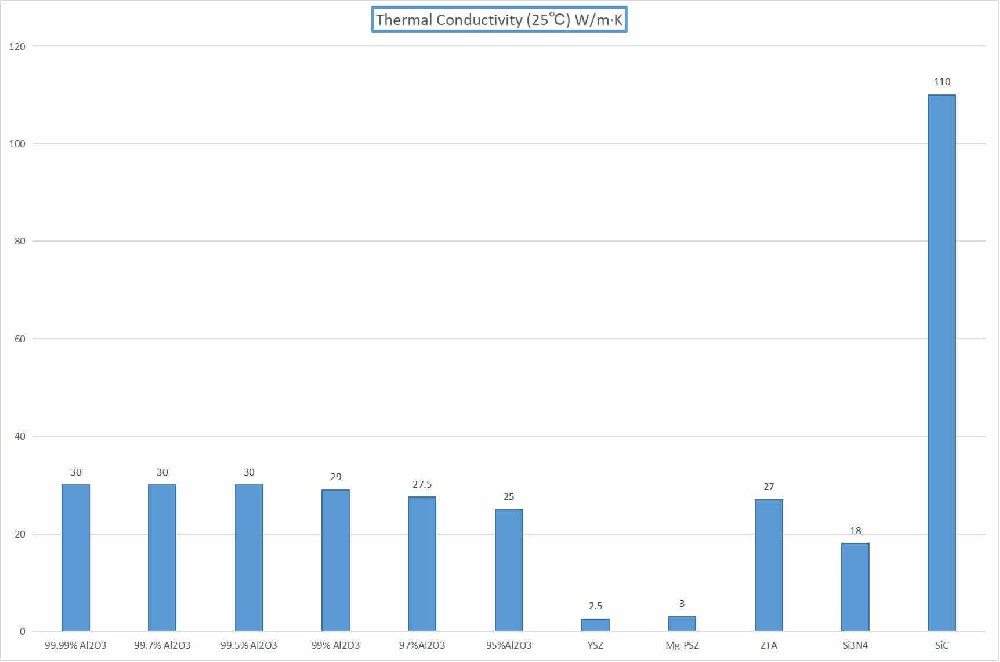

3, Most of the structural ceramics have superior strength, hardness, insulation, heat conduction, high temperature resistance, oxidation resistance, corrosion resistance, wear resistance and other characteristics.

Physical properties

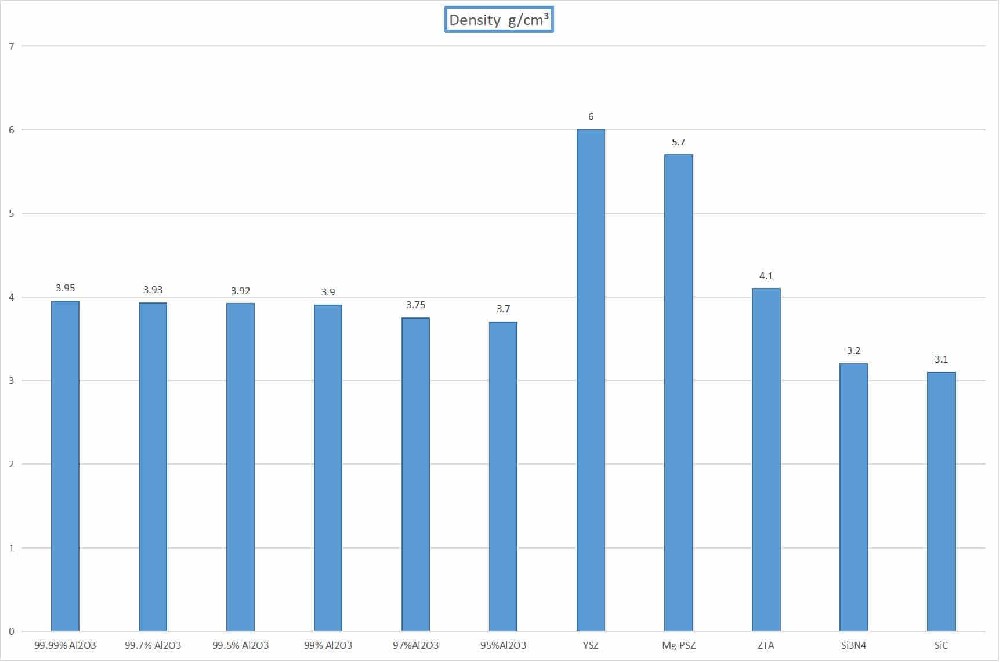

Density

The density is usually between 2.2 and 3.0 g/cm³. The size of the density affects the quality and strength of the ceramic sheet. Ceramic sheets with higher density often have better wear resistance and compressive strength.

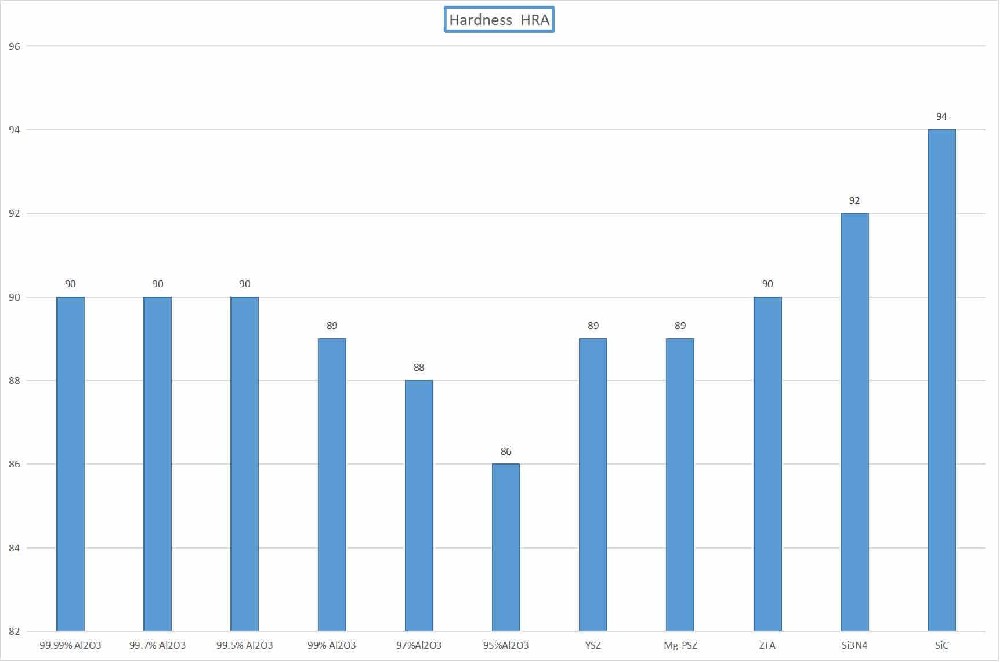

Hardness

It is generally around grade 6 to 7. Its high hardness makes it less likely to be scratched or worn during use, and it can maintain a relatively long smoothness and service life.

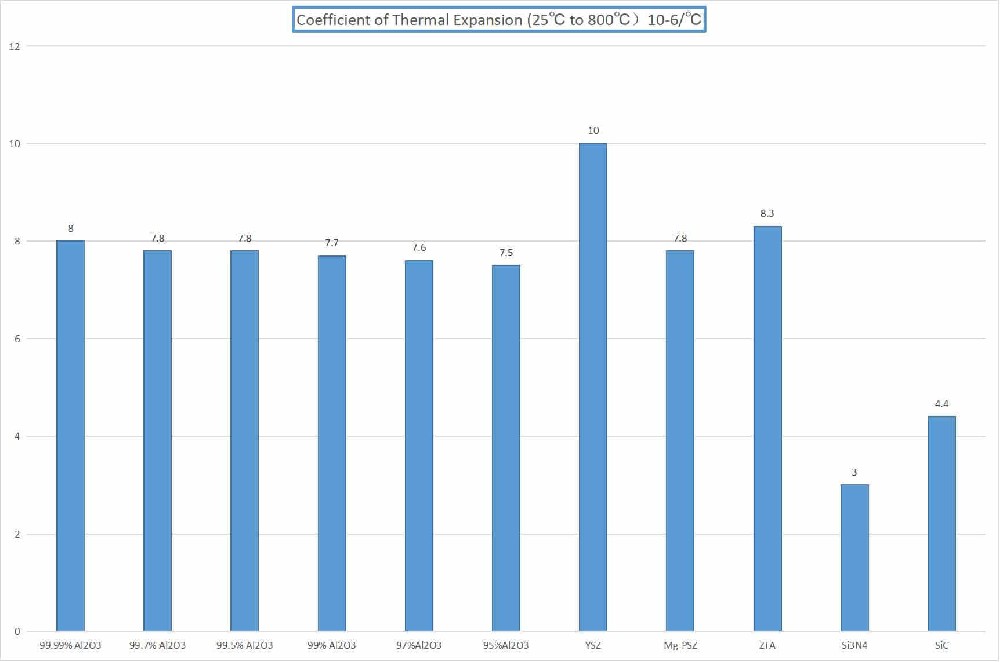

Coefficient of thermal expansion

The coefficient of thermal expansion is approximately 5-8×10⁻⁶ /. The size of the coefficient of thermal expansion determines the dimensional stability of the ceramic sheet when the temperature changes. An appropriate coefficient of thermal expansion helps to avoid problems such as cracks caused by temperature changes.

In terms of mechanical properties

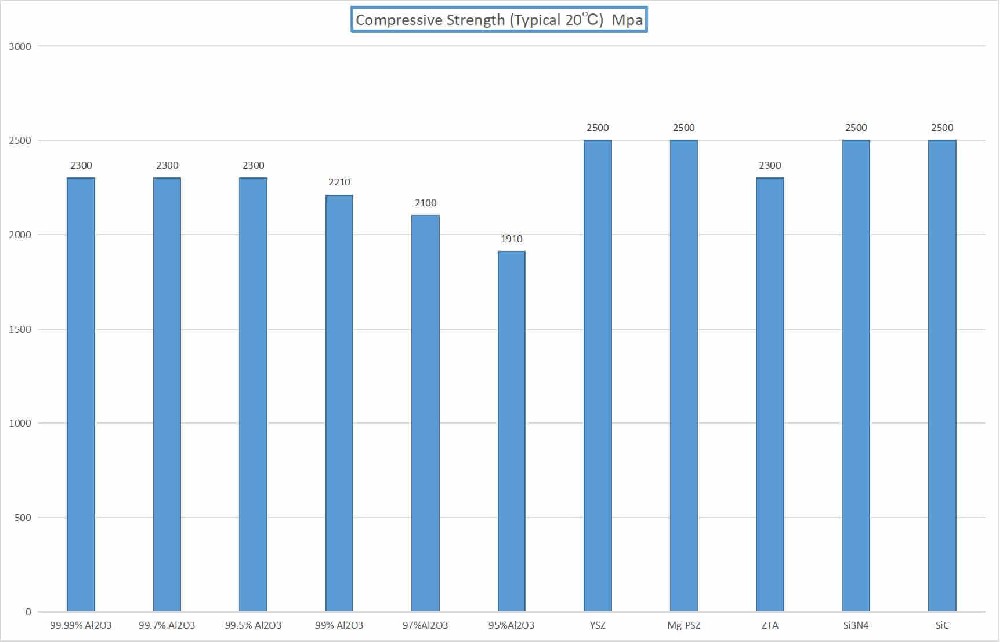

Compressive strength

It can reach hundreds of megapascals or even higher, which makes the ceramic sheet have a strong ability to withstand vertical pressure and is suitable for some high-pressure environment applications.

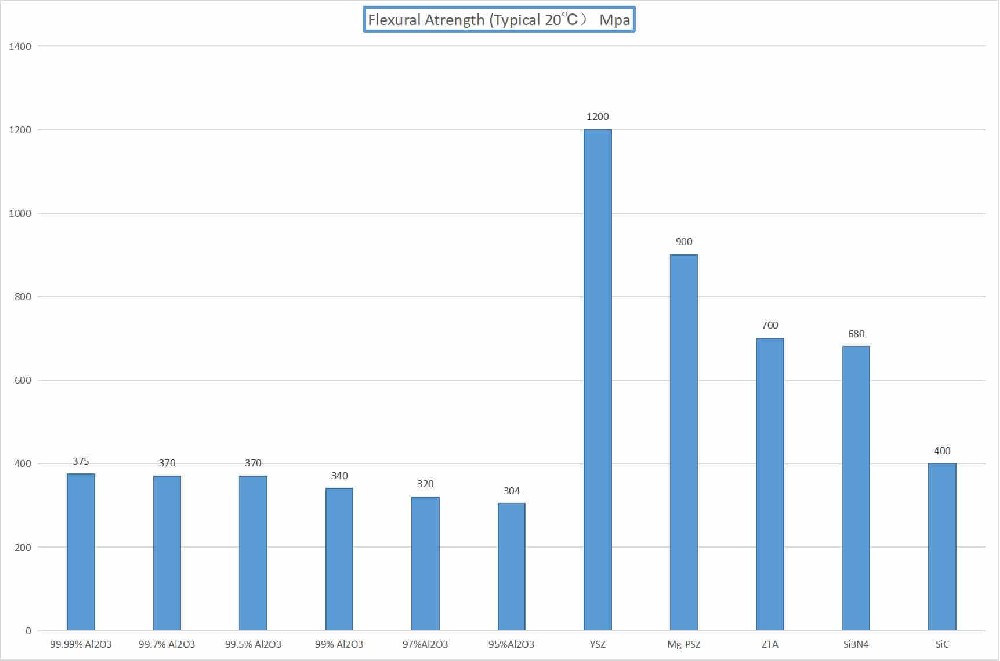

Flexural strength

The flexural strength is generally between 50 and 200 MPa. It reflects the ability of ceramic plates to resist bending deformation and fracture. A higher flexural strength enables them to be less prone to damage when subjected to bending force.

Impact resistance strength

Typically within the range of 5 to 15 J/cm², the impact resistance strength reflects the ceramic sheet's ability to withstand sudden impact forces. A better impact resistance strength enables it to resist external impacts to a certain extent without cracking.

In terms of chemical properties

Corrosion resistance

It has good resistance to a variety of chemical substances, such as acids, alkalis, salts, etc. In some complex acidic and alkaline environments, ceramic plates can maintain stable performance and are not easily corroded.

Antioxidant property

Ceramic sheets can resist the oxidation of oxygen in high-temperature environments and are less likely to undergo oxidation reactions that lead to performance degradation. This makes them widely used in high-temperature stoves and other fields.

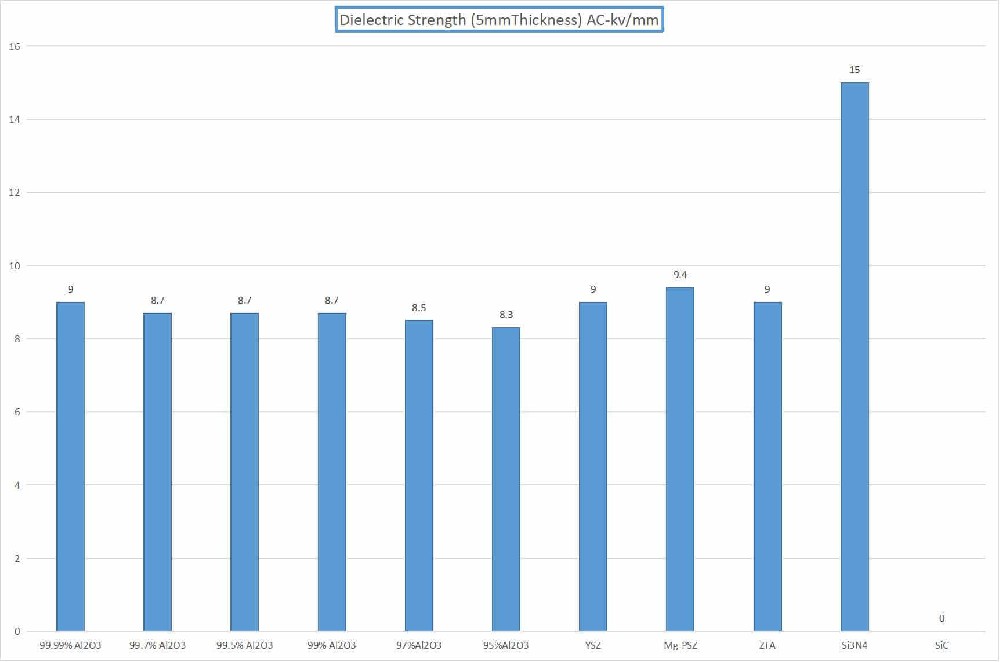

In addition, there are electrical performance parameters, such as insulation resistance and dielectric constant, which are quite important for some ceramic applications related to electricity. And optical performance parameters, such as light transmittance and refractive index, play a role in specific optical fields. These performance parameters interact with each other and jointly determine the applicability and application effect of ceramics in different fields.