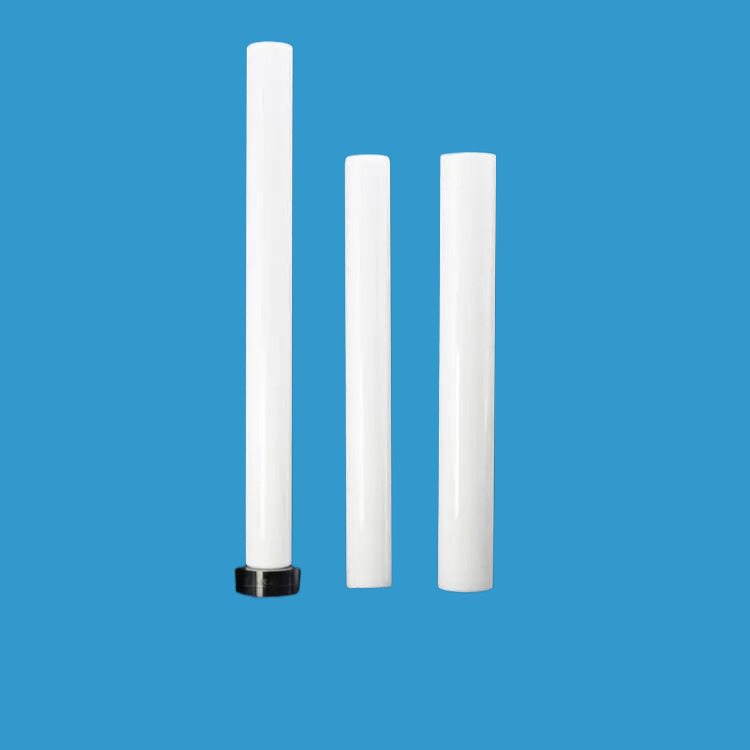

ceramic plunger shaft

The ceramic plunger is made of modern engineering ceramic material with super-hard wear resistance, and can be assembled by ceramic metallization bonding, welding, Mosaic and socket technology. It is an ideal substitute for similar metal pumps, and has been widely used in medical equipment, environmental engineering, petroleum, chemical and other industries.

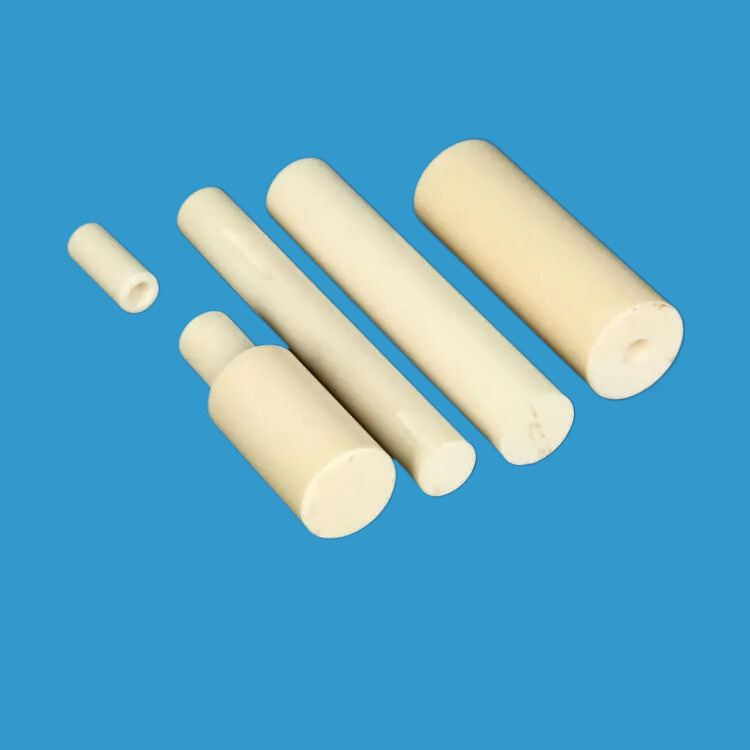

Ceramic plug using high-performance technology ceramic materials, after high temperature 1600℃ sintering isostatic pressing process molding and unique design, the product has corrosion resistance to high temperature, the use of the process does not soften, do not open, do not peel and other characteristics, long service life

Ceramic plungers are widely used in medical equipment, environmental engineering, petroleum, chemical and other industries, suitable for petroleum, chemical, machinery and other precision and corrosive substances more industries. The use of ceramic plungers instead of metal plungers in mechanical plunger applications can effectively solve the problem of short equipment life caused by poor corrosion resistance and low working temperature resistance of metal plungers.

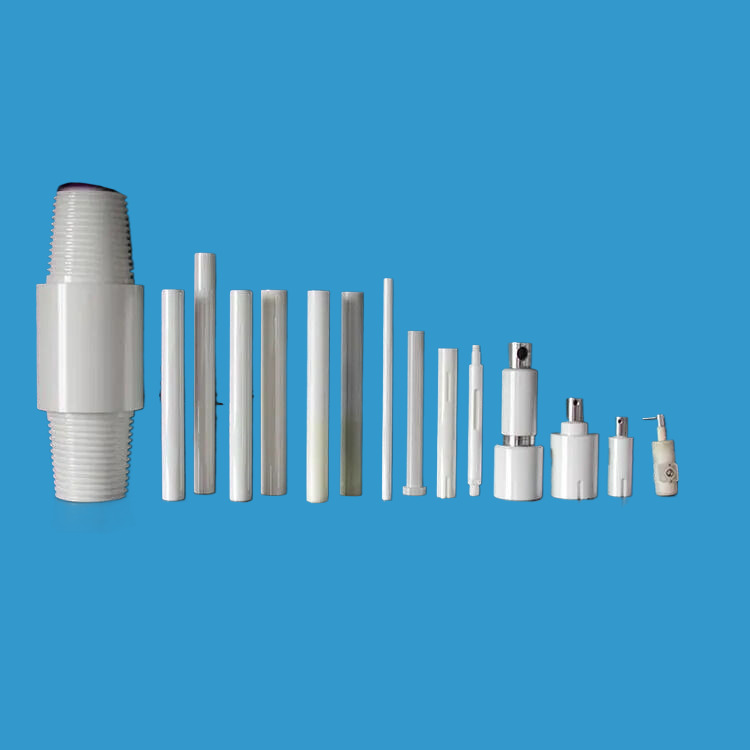

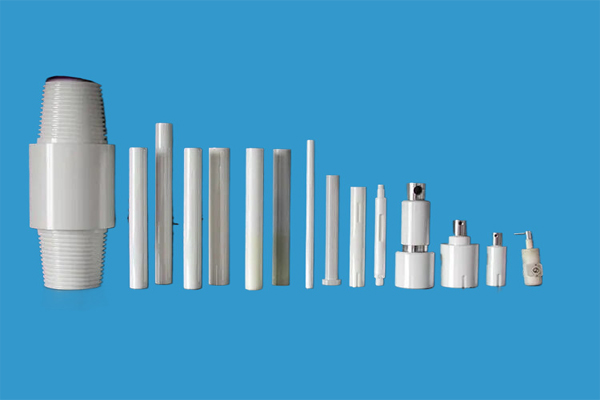

Type of ceramic plunger/ shaft:

Pump Plunger, Valve Rod, Plunger Pins, Piston Plunger, Pump Shaft, Piston Rod, Shaft... etc

Application of ceramic plunger:

·Liquid Pumps ·Metering Pumps ·High Pressure Pumps ·Mud Pumps ·Pump Seals ·Valve Pumps etc

Materials:

Alumina, zirconia, silicon nitride, silicon carbide.

Parameter type

Sizes: Diameter:3-60mm; length:20-650mm

Ceramic plunger shaft machining parameter

The parameters of the ceramic plunger include dimensional accuracy, finish, hardness, parallelism, cylindricity and single section roundness.

The dimensional accuracy has reached 0.001mm, to ensure the high precision requirements of the ceramic plunger.

The finish is less than Ra0.02, ensures the smooth degree of the ceramic plunger surface, is conducive to reducing friction and wear.

The hardness range is Hv1280-1340, shows the wear and pressure resistance of the ceramic plunger.

Parallelism and cylindricity are controlled within 0.01mm and 0.003-0.01mm respectively, ensures the geometric shape accuracy of the ceramic plunger, is conducive to improving the performance and life of the pump.

The circularity of a single section is less than 0.001, further ensures the accuracy of the geometry of the ceramic plunger.

Advantages of ceramic shaft

- 1. Good wear resistance: ceramic materials have the characteristics of high hardness and low friction coefficient, making ceramic shafts able to withstand higher loads and rotation speeds, and long service life.

- 2. Strong corrosion resistance: ceramic material has excellent chemical stability, is not easy to be corroded by acid, alkali, salt and other chemical substances, can be used in harsh environments.

- 3. Good high temperature resistance: ceramic shaft can maintain stable physical properties in high temperature environment, not easy to deformation, burn, with high thermal stability.

- 4. Weight reduction: Due to the low density of the ceramic material itself, the use of ceramic shafts can effectively reduce the total weight of the equipment.

- 5. Good sealing performance: Due to the high surface finish of the ceramic material, the ceramic plunger can get a good sealing effect.

Application scenario of ceramic plunger

- 1. Automotive engine: Ceramic plungers can be used in the injection system of automotive engines to improve fuel injection accuracy and combustion efficiency and reduce exhaust emissions.

- 2. Hydraulic system: Ceramic plungers can be used for sealing and flow control in hydraulic pumps or hydraulic motors.

- 3. Medical devices: Ceramic plungers can be used in high-precision infusion and injection systems in medical devices to ensure that the liquid does not leak out.

- 4. Chemical equipment: Ceramic plungers can be used for high temperature, high pressure and corrosive liquid flow control in chemical equipment.

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.