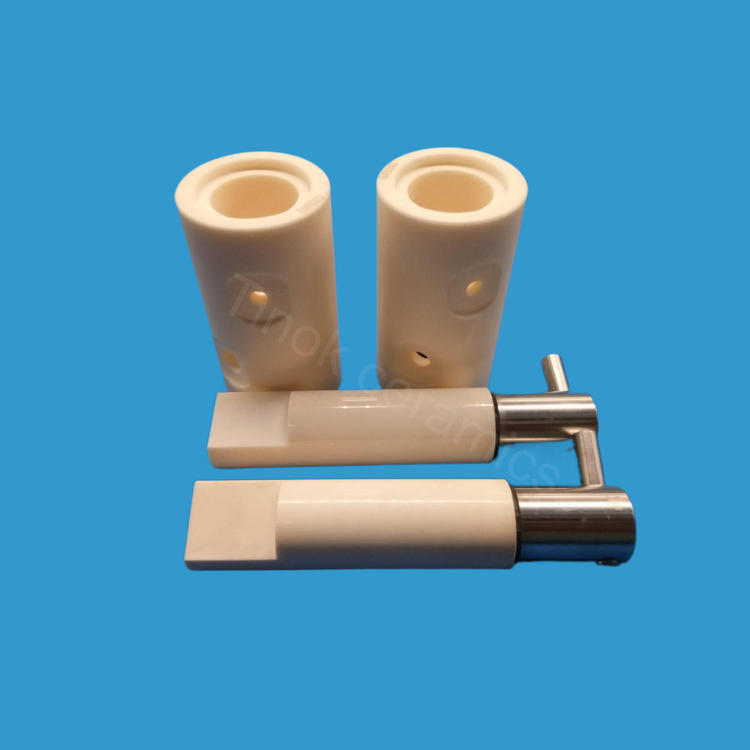

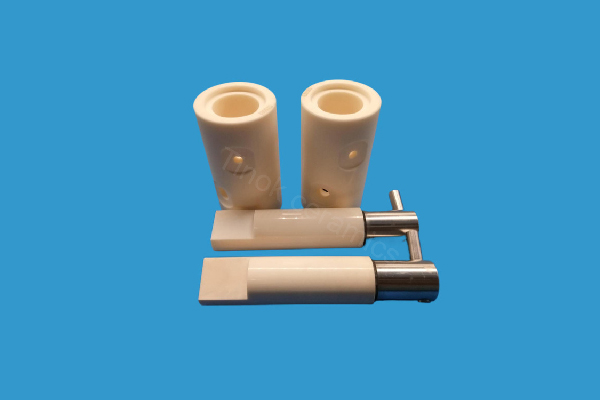

ceramic pump

Ceramic pumps corrosion anti high temperature wear resistance ceramic piston metering filling pump

Ceramic pump adopts high performance technology ceramic material, which has high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties. Because of its high hardness and excellent wear resistance, it can effectively improve the service life of the pump body and reduce maintenance costs. At the same time, its high temperature resistance, corrosion resistance and other properties also ensure the stability and reliability of the pump body in various complex environments.

Ceramic pump adopts high performance technology ceramic material, which has high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties. Because of its high hardness and excellent wear resistance, it can effectively improve the service life of the pump body and reduce maintenance costs. At the same time, its high temperature resistance, corrosion resistance and other properties also ensure the stability and reliability of the pump body in various complex environments.

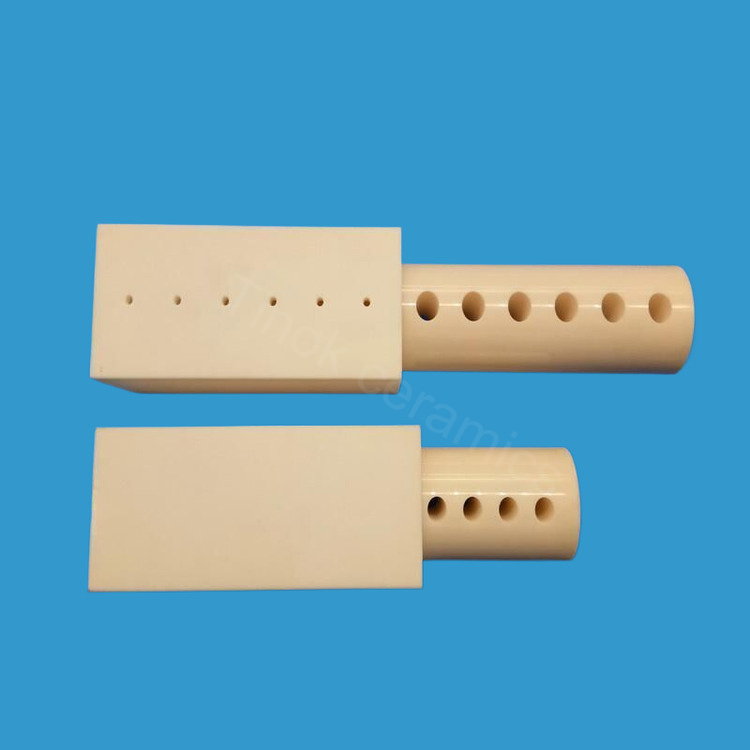

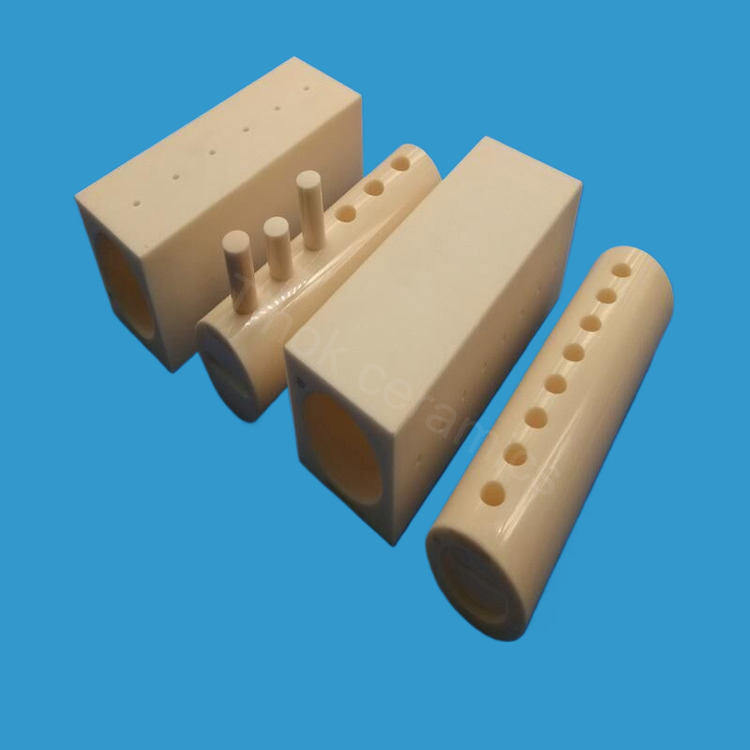

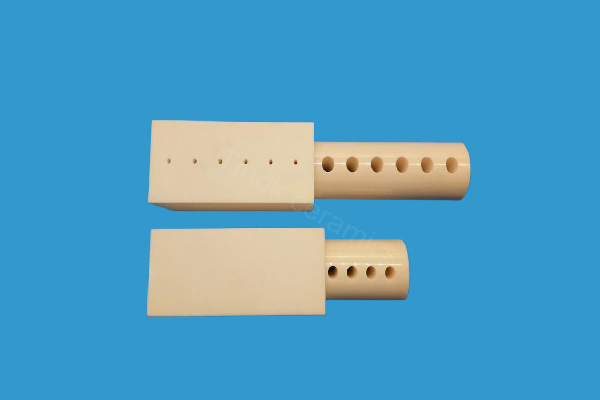

We can customize the ceramic filling pump, ceramic metering pump, ceramic liquid injection pump and other ceramic plunger pumps according to the customer's drawings and requirements. Ceramic pump products are widely used in various fields, our product series includes: ceramic plunger pump, ceramic filling pump, ceramic dosing pump, ceramic metering pump, etc.

Ceramic pump type

Structural ceramic pump

Structural ceramic pump is one of the most widely used ceramic pump types at present, with simple structure and convenient operation. Its main components are pump head, pump body, rotating shaft, impeller and so on. Structural ceramic pump with excellent wear resistance and corrosion resistance, widely used in chemical, food and other industrial fields.

Ceramic plunger pump

The plunger ceramic pump is composed of a plunger, a guide rod and a pump body, and adopts reciprocating movement to achieve liquid transportation. Plunger type ceramic pump is suitable for conveying liquid viscosity, solid particles and corrosive liquids.

The processing parameters of ceramic metering pump include processing range and processing precision

The machining range involves outer diameters from 1mm to 100mm, inner diameters from 0.1mm to 80mm, and lengths from 0.5mm to 400mm. These parameters ensure that the ceramic metering pump can be adapted to a variety of application scenarios and filling requirements.

Processing technology, processing range (mm) : outer diameter 1-- 100, inner diameter 0.1-- 80, length 0.5-- 400;

Machining accuracy (mm) : verticality 0.01, concentricity 0.01, roundness 0.005, straightness 0.005, parallelism 0.01, flatness 0.005, roughness 0.05, fit clearance 0.005.

In terms of machining accuracy, ceramic metering pump has reached the high precision standards, including the specific values of perpendicularity, concentricity, roundness, straightness, parallelism, flatness and roughness. These precision parameters ensure that the performance of the ceramic metering pump is stable and reliable, can meet the needs of various precision filling.

In addition, ceramic metering pump also has specific technical indicators, such as the filling range from 0.2ml to 50ml, the use temperature is between 10℃ and 40℃, filling accuracy standards vary according to the filling volume, less than 2ml filling volume up and down deviation does not exceed ±1%, more than 2ml filling volume up and down deviation does not exceed ±0.5%. These technical specifications together ensure the performance and accuracy of the ceramic metering pump in a variety of working environments.

Ceramic pump features

- 1. High corrosion resistance. Ceramic pump is a non-metallic pump, not easy to rust, will not be corroded by corrosive liquid, can work in corrosive environment for a long time.

- 2. High temperature wear resistance. Ceramic pump can work in high temperature environment, its thermal expansion coefficient is similar to most metals, so it has excellent temperature performance. At the same time, the excellent anti-wear performance of the ceramic pump enables it to work stably for a long time in a high-speed flow state.

- 3. Wear resistance. The hardness of ceramic pumps is several times that of steel and can withstand greater wear. The parts of the pump and the base are connected with threads to make the pump body more firm.

- 4. Excellent electrical performance: ceramic positioning pins have good electrical insulation properties and can be used to make various electrical components.

- 5. environmental protection and pollution-free: ceramic is an environmentally friendly material, the preparation process does not produce harmful substances, friendly to the environment.

Ceramic pump application field

- 1. Chemical industry. Ceramic pumps are widely used in corrosive liquid transportation, fluorine chemical industry, pharmaceutical production and other fields.

- 2. Pharmaceutical industry. Ceramic pumps are also widely used in transportation, separation and preparation processes in the pharmaceutical industry.

- 3. Electronics industry. Ceramic pumps can also be used in electroplating, semiconductors, solar cells and other fields in the electronics industry.

- 4. Thermal field: Ceramic positioning pin has excellent high temperature resistance, can be used to make thermocouple casing, high temperature furnace and other thermal equipment.

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.