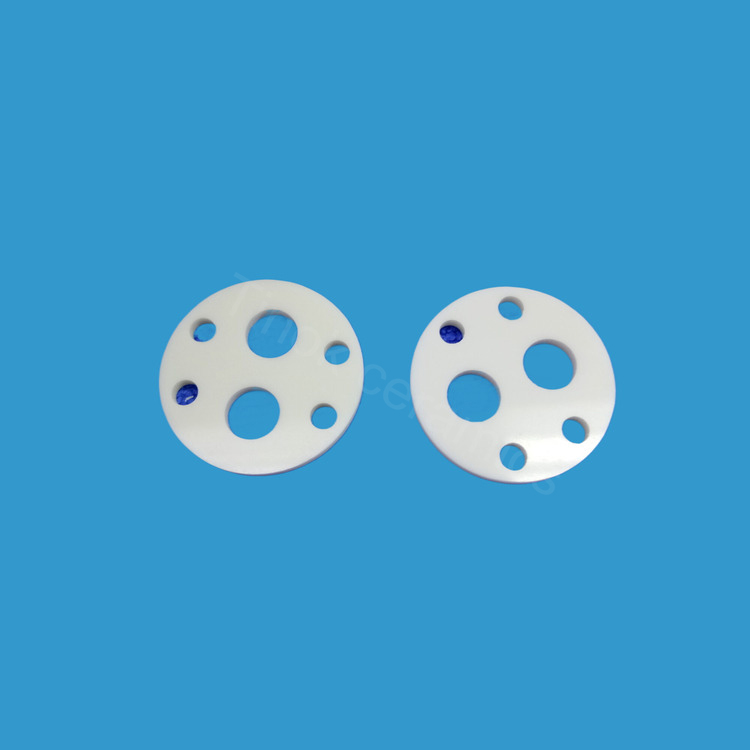

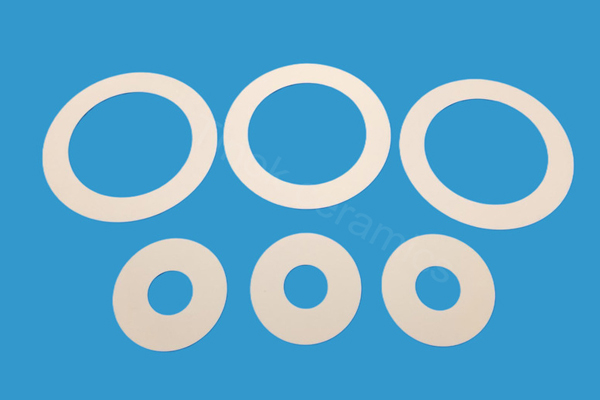

ceramic ring

Ceramic ring high corrosion high wear resistance ceramic sealing rings

Ceramic rings are annular industrial parts made of ceramic materials. It is often used in various reactors in chemical industry, metallurgy, electric power, machinery and other fields to increase the reaction area, promote mass transfer reaction, and enhance the reaction effect. According to different structures and uses, ceramic rings can be roughly divided into ring skeleton ceramic rings, shift-filled ceramic rings and filled ceramic rings.

Ceramic sealing ring is better than other materials in chemical corrosion resistance, wear resistance, high temperature resistance and other properties, and is widely used in machinery, chemical industry, petroleum, food, pharmaceutical, automotive and other fields.

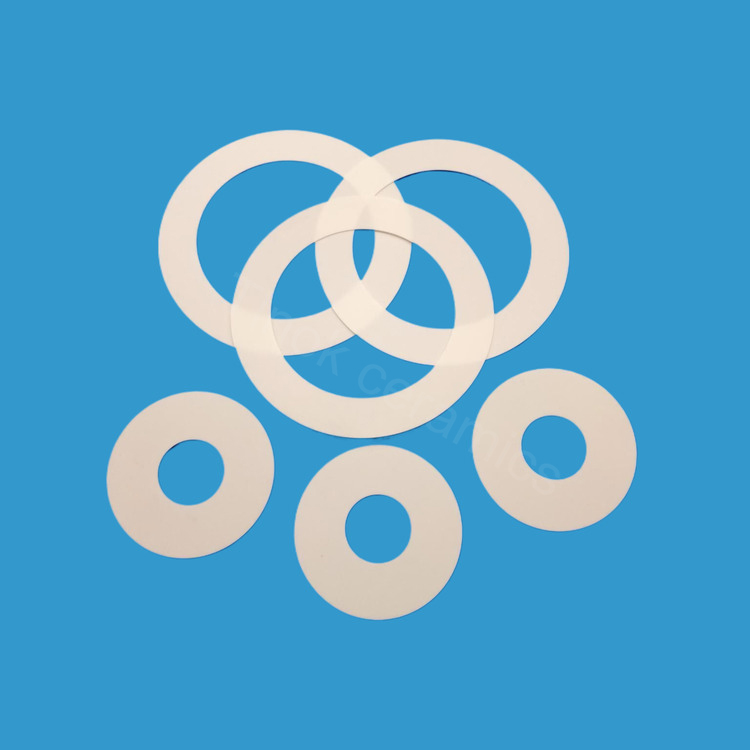

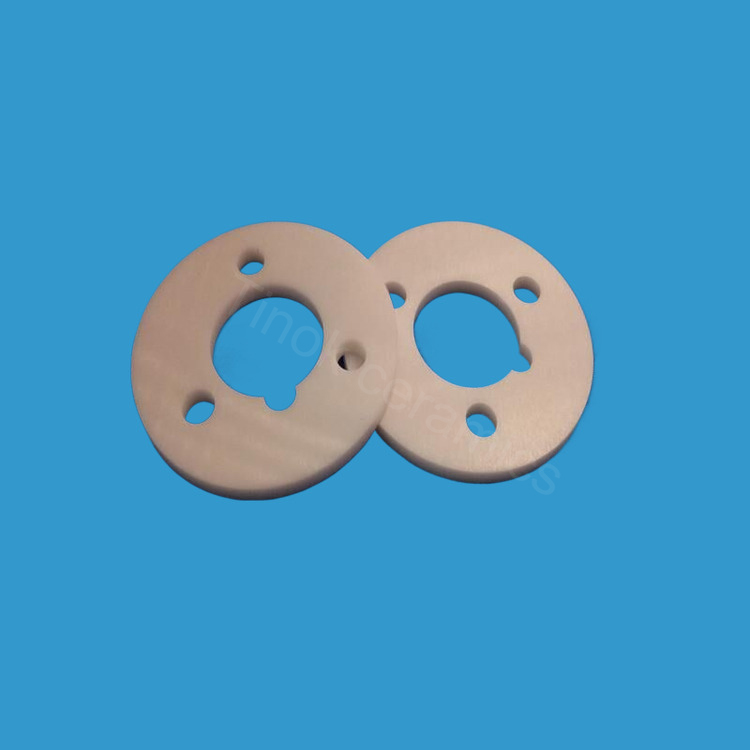

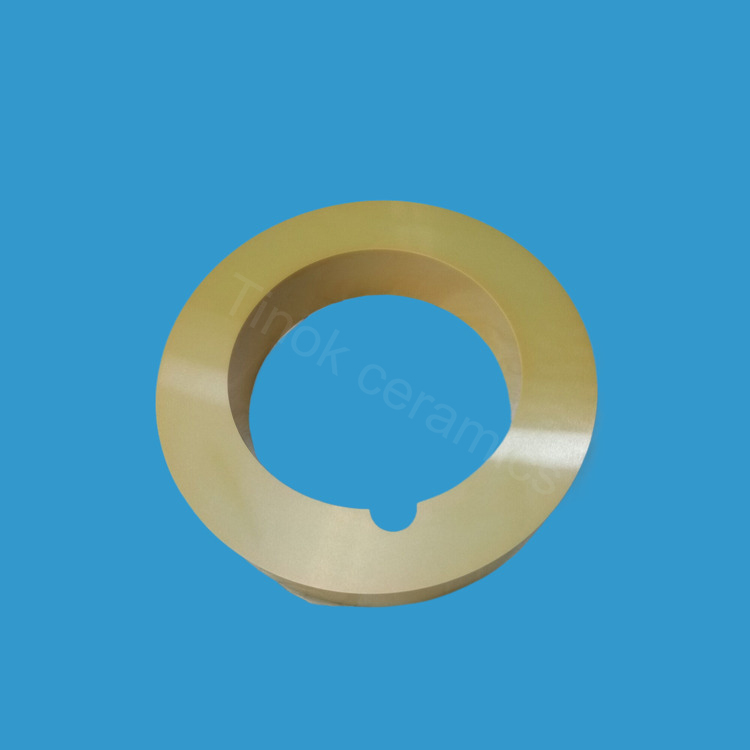

Ceramic ring sealing ring is a kind of sealing ring made of ceramic material, its structure is relatively simple, usually composed of two parts: inner and outer ring.

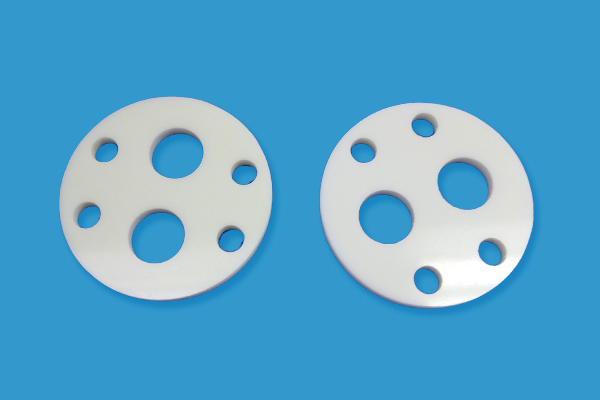

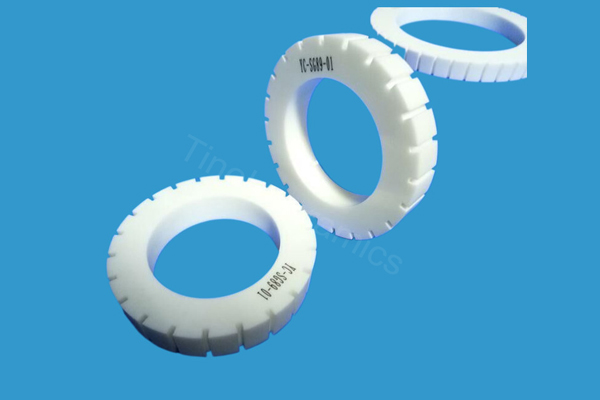

Ceramic ring sealing ring is a kind of sealing ring made of ceramic material, its structure is relatively simple, usually composed of two parts: inner and outer ring. The inner ring is usually placed directly on the shaft, while the outer ring is mounted on the housing or sealing seat. The main characteristics of ceramic ring seals are high corrosion resistance, high wear resistance, high heat resistance and so on. In addition, the characteristics of ceramic materials themselves also include good insulation, high hardness, high strength advantages.

Parameter type

Ceramic ring using dry pressing, hot pressing, isostatic pressing and other forming processes, made of 95, 99 alumina ceramic ceramic seals, ceramic rings, ceramic tubes, mirror polishing processing, accuracy up to ±0.01,

Specifications: Caliber 100mm-- 650mm, length 100-- 1600mm, wall thickness 5-- 300mm

Dimension :

Inside Diameter as small as 0.3 mm; inside diameter as small as 0.3 mm; tolerance as fine as 0.002mm

Outside Diameter as big as 400mm; tolerance as fine as 0.001mm

Can be custom other sizes and shapes for the rings

Precautions for selecting ceramic rings

1. Select the appropriate ceramic ring material according to the actual use, pay attention to its corrosion resistance, high temperature resistance, wear resistance and other characteristics.

2. Select the appropriate ceramic ring to ensure that it is fully matched with the reactor and does not affect the normal use of the reactor.

3. Check the size and appearance of the ceramic ring to ensure that there are no burrs, cracks and other defects.

Ceramic seal ring characteristics

- 1, chemical corrosion resistance: strong acid, strong alkali resistance is better than other materials;

- Wear resistance: not easy to wear, strong durability;

- Heat resistance: high mechanical strength at high temperature, can be applied to high temperature conditions;

- 5. Good sealing performance: Due to the high surface finish of the ceramic material, the ceramic plunger can get a good sealing effect.

Application of ceramic seal ring

Ceramic ring seals are widely used in machinery industry, chemical industry, metallurgy industry and other fields. It is used to make airtight, watertight, dust-proof, shock absorption and insulation materials, etc., which plays a good sealing effect, thus avoiding the failure of mechanical parts due to dust, oxidation and other reasons. At the same time, the high strength ceramic sealing ring can also be used for the sealing of high pressure, high speed and high speed motion equipment.

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.