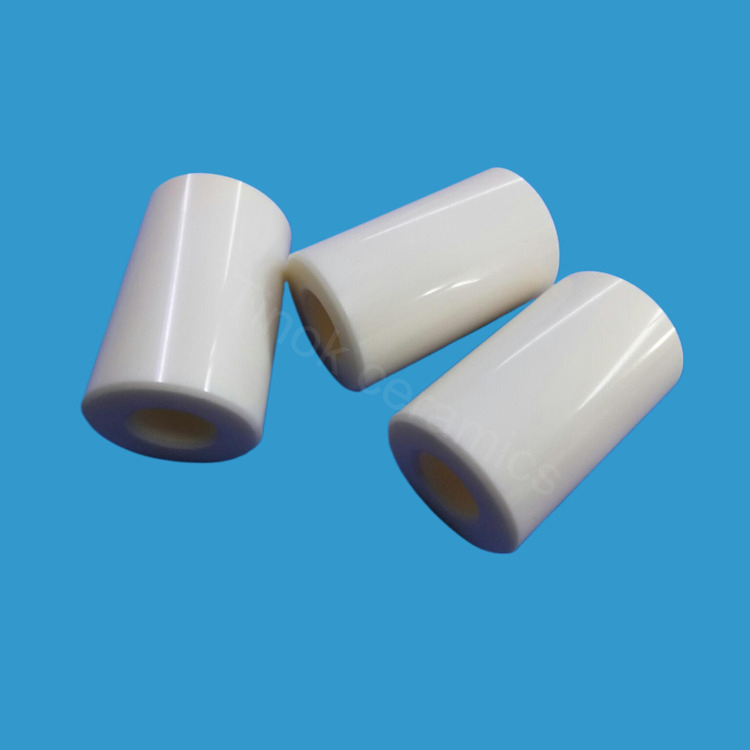

Ceramic sleeve high strength wear resistant insulating alumina zirconia ceramic sleeving bushing

Ceramic sleeve is a part commonly used in mechanical sealing, which is usually composed of two parts, an inner sleeve and an outer sleeve. Among them, the inner sleeve is made of ceramic ring structure, used to contact with the shaft sleeve, the outer sleeve is metal material, used to connect with the sealing end, so as to achieve the sealing function. Ceramic sleeve has the advantages of good thermal stability, corrosion resistance, wear resistance, etc., so it has been widely used.

Ceramic sleeve is a kind of sleeve made of new ceramic material, has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance and insulation. This kind of sleeve is usually made of zirconia ceramic material, can work continuously without oil lubrication at high temperature, is suitable for electronic, aviation, chemical industry and other fields.

Ceramic sleeve property

· Flexural strength

· Chemical resistance

· Electrical insulation

· Corrosion resistance

· Dielectric strength

· Wear resistance

· Temperature resistance

· Thermal conductivity

· High voltage

· Hardness...

Ceramic sleeve definition

Ceramic sleeve is a part commonly used in mechanical sealing, which is usually composed of two parts, an inner sleeve and an outer sleeve. Among them, the inner sleeve is made of ceramic ring structure, used to contact with the shaft sleeve, the outer sleeve is metal material, used to connect with the sealing end, so as to achieve the sealing function. Ceramic sleeve has the advantages of good thermal stability, corrosion resistance, wear resistance, etc., so it has been widely used.

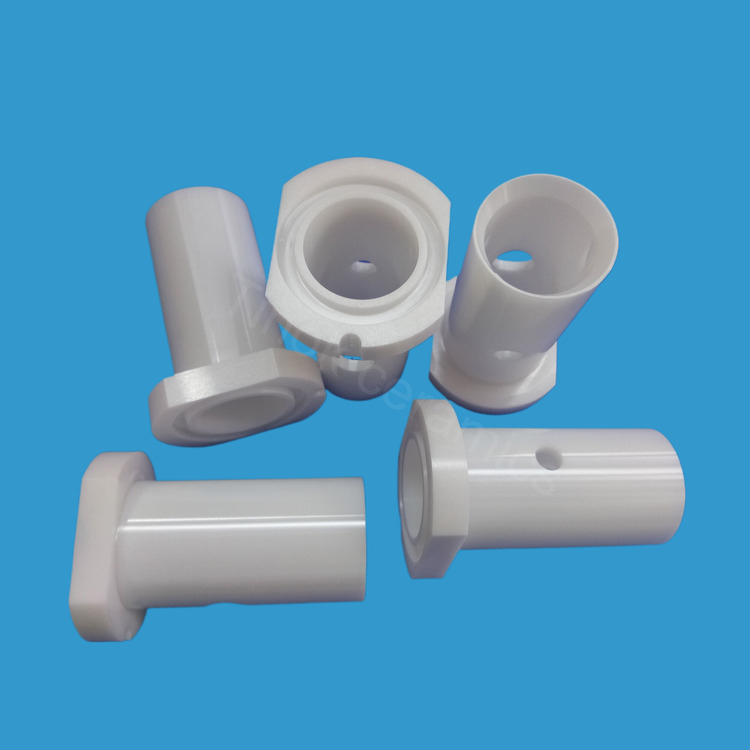

Material selection of sleeve in ceramics

Ceramic sleeve is mainly made of alumina, silicon nitride, zirconia and other materials, of which alumina is the most widely used, followed by silicon nitride and zirconia. These materials have good high temperature resistance, corrosion resistance, wear resistance and other properties.

Material | 95%-99.99% alumina ceramic(Al2o3); zirconia ceramics; silicon carbide ceramics; silicon nitride ceramics..etc |

Color | White or Black or Yellow |

Size | According to drawings or samples |

Surface Roughness | Ra0.05 |

Torlerance | +/- 0.02mm |

Lead time | 10 - 30days |

Shipping | Air Express (DHL/UPS/TNT/ FedEx) |

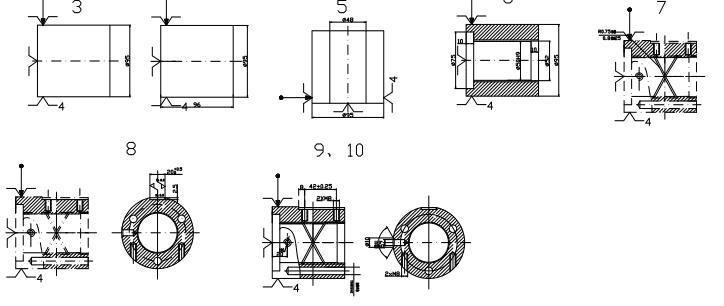

Ceramic sleeve size and processing parameters

Ceramic sleeve refers to the sleeve type parts made of ceramic materials. There are a variety of sizes, with common internal diameters ranging from 10 mm to 500 mm and lengths ranging from 10 mm to 1000 mm. The specific size specifications should be selected according to the use occasion and specific use needs to meet the production needs.

Manufacturing process of sleeve in ceramics

The manufacturing process of ceramic sleeve mainly includes the preparation of raw materials, molding, sintering and other steps. In the molding process, you can choose injection molding, static pressing, plasma spraying and other methods, different processes have different effects on the performance of the sleeve in the ceramic.

Ceramic sleeve applications

Because the sleeve in ceramic has good wear resistance and corrosion resistance, it has been widely used in some special environments. For example, in the petroleum, chemical, electric power and other fields, liquid and gas pipeline in the high temperature, high pressure, corrosion and other extreme environment, the use of ceramic sleeve can effectively ensure the safe operation of mechanical equipment.

As a new type of seal with high strength, high precision, high reliability, high temperature resistance, corrosion resistance and wear resistance, ceramic sleeve is widely used in chemical industry, electric power and other fields. Although the production cost is relatively high, the excellent performance in extreme environments is very considerable compared to the economic benefits.