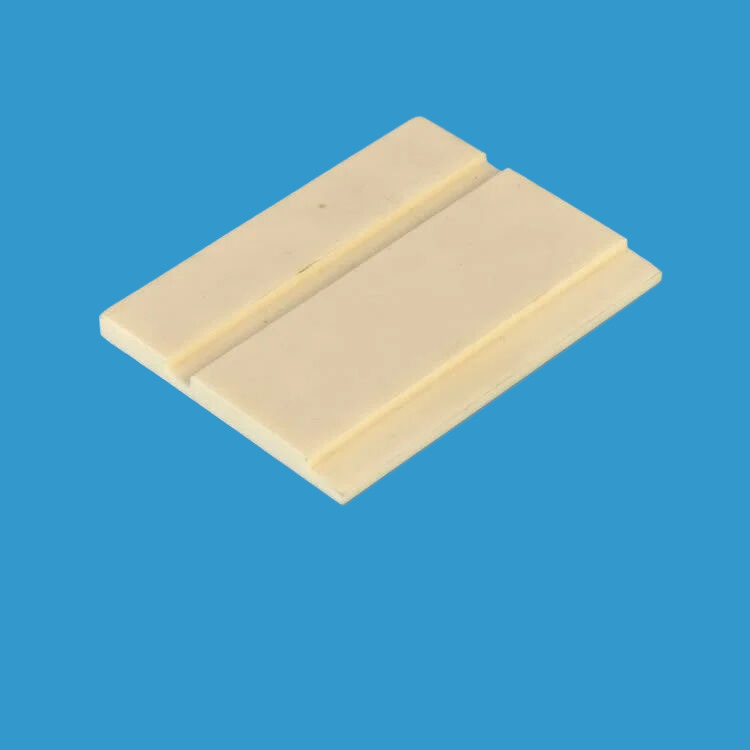

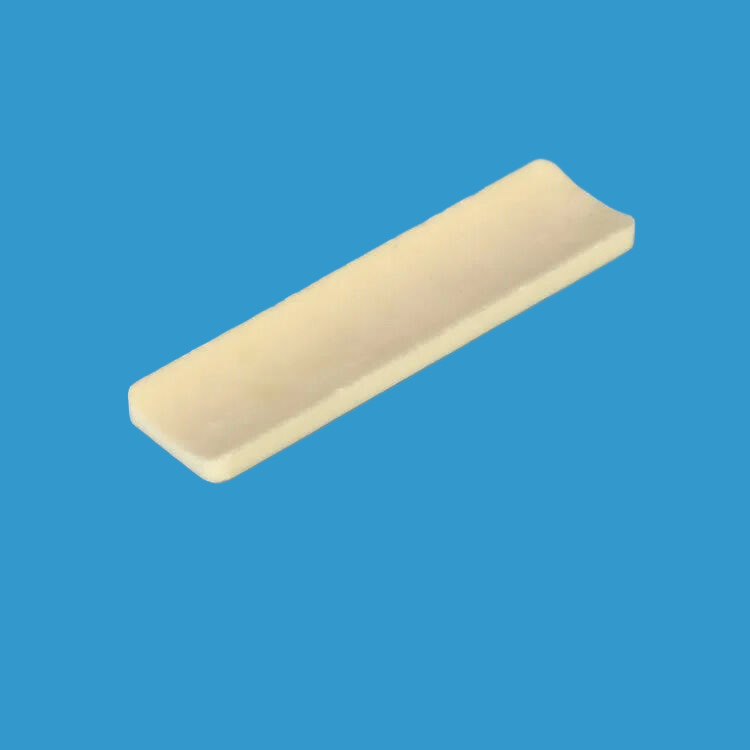

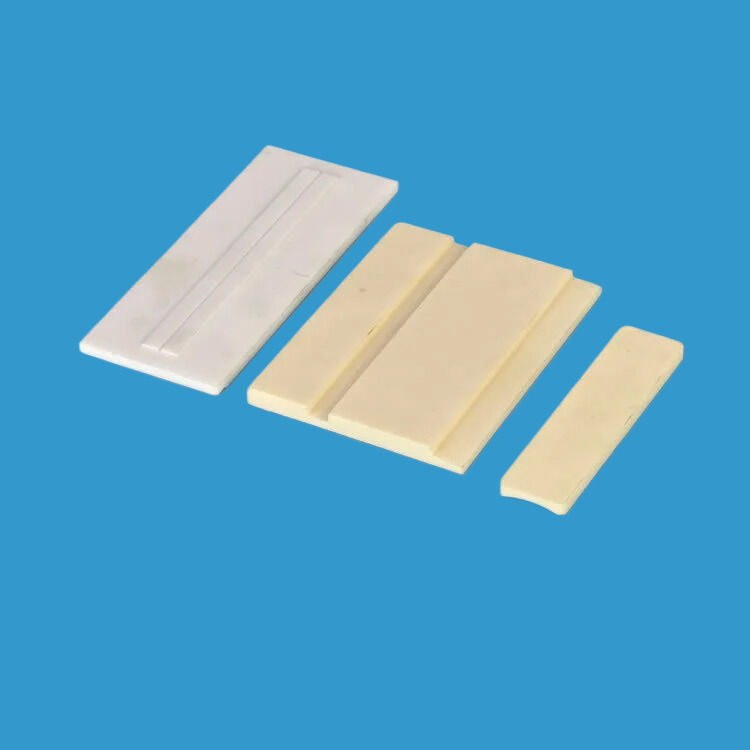

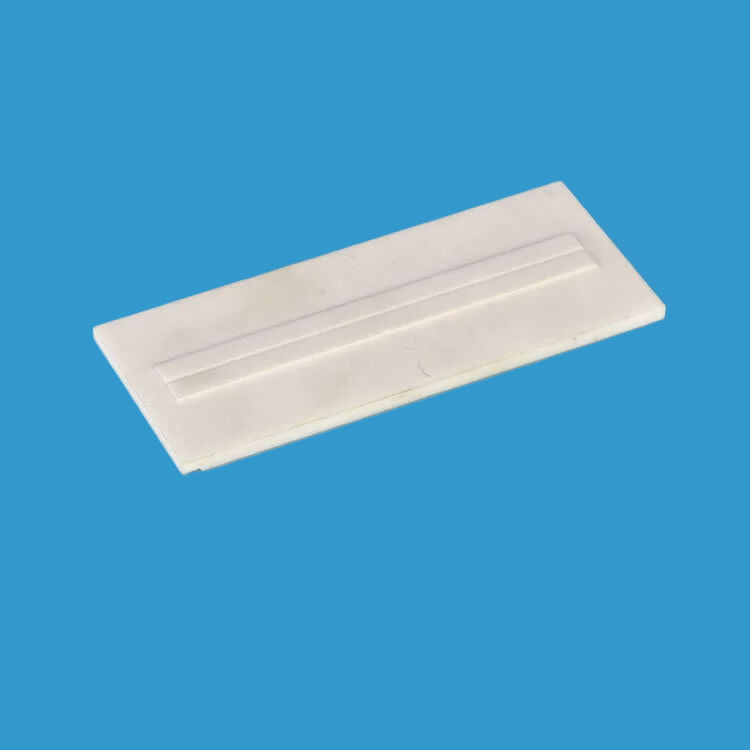

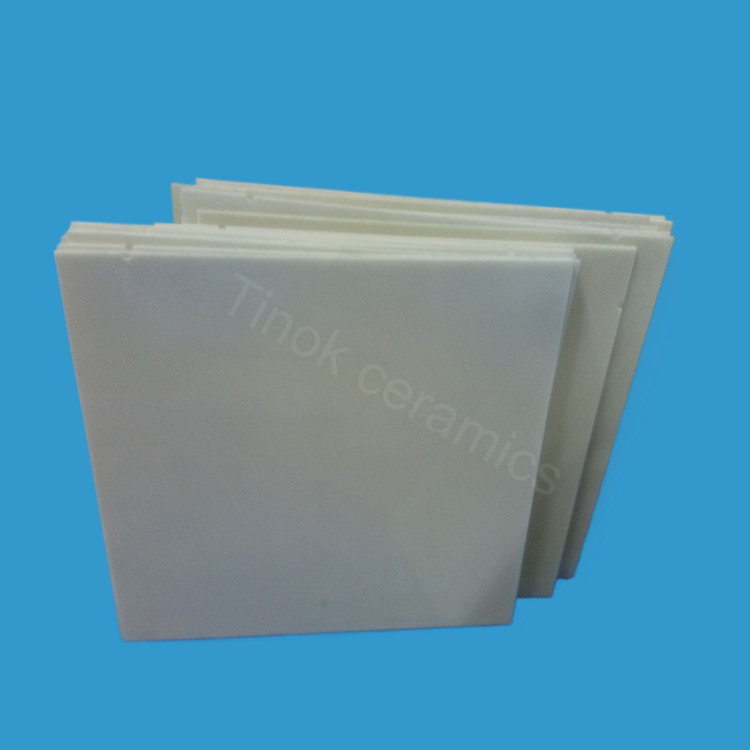

ceramic substrate plate

Ceramic substrate plate is mainly made of alumina or zirconia raw materials, with high hardness, high density and high wear resistance. It has extremely high compressive strength and can withstand high pressures and heavy loads. In addition, it also has excellent heat resistance and can operate stably at high temperatures for a long time. This ceramic plate has excellent chemical stability and good resistance to corrosive substances such as acid and alkali. The physical properties of alumina ceramic substrate plate make it an ideal engineering material.

Materials and specifications

The raw materials of ceramic plate can be selected: zirconia, alumina, silicon nitride and other advanced ceramics.

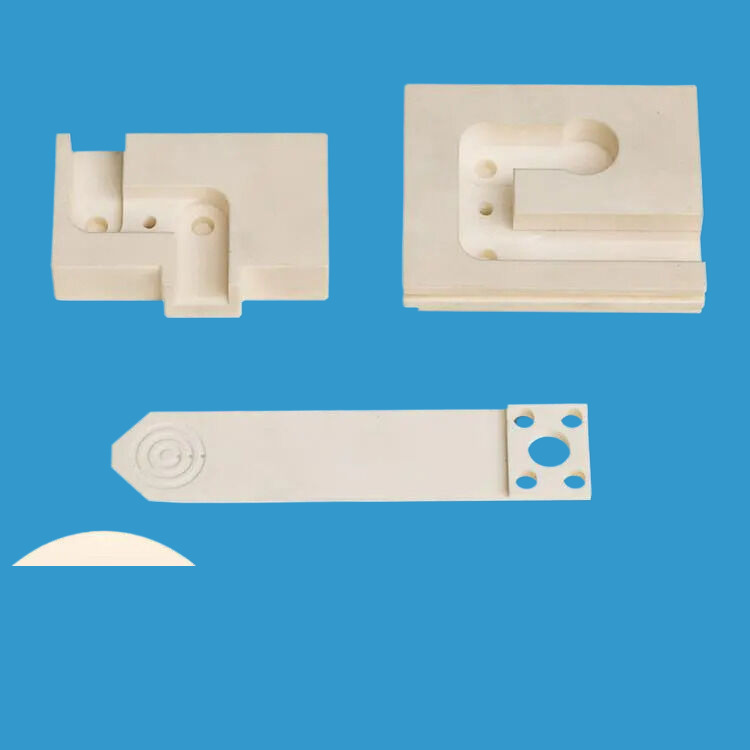

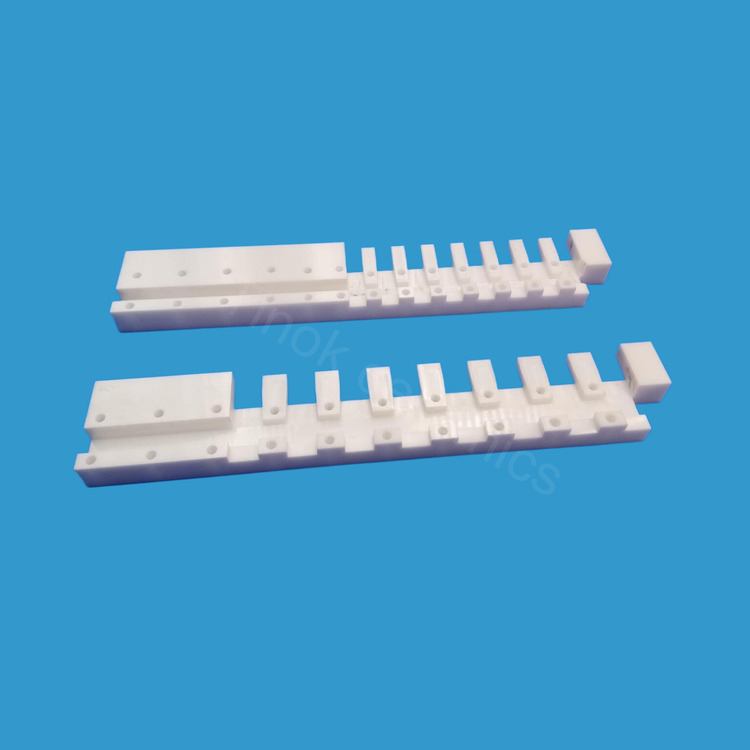

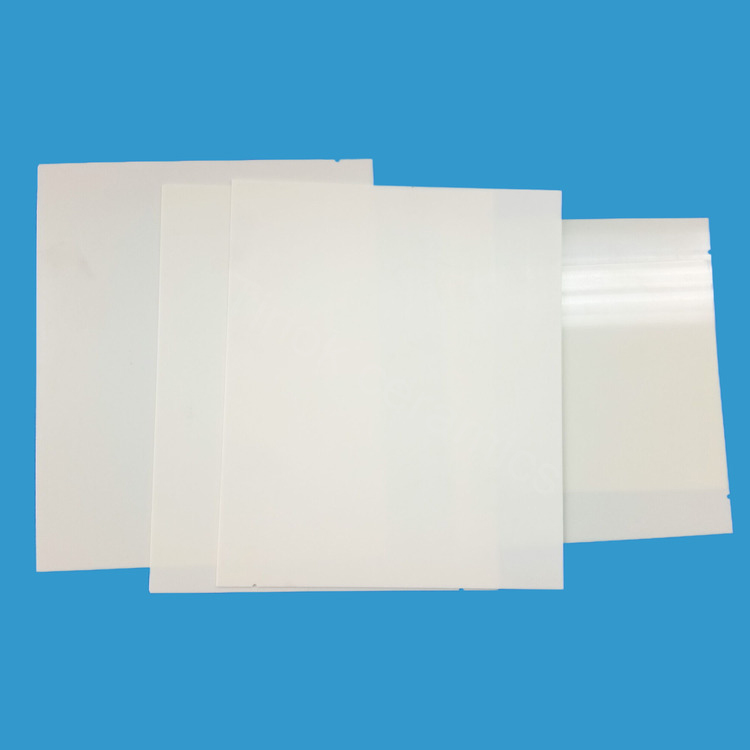

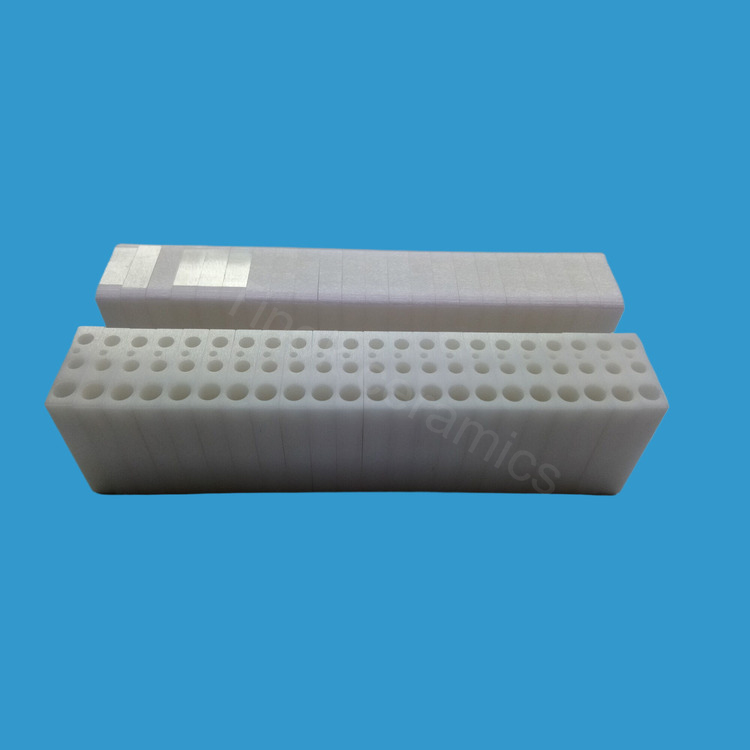

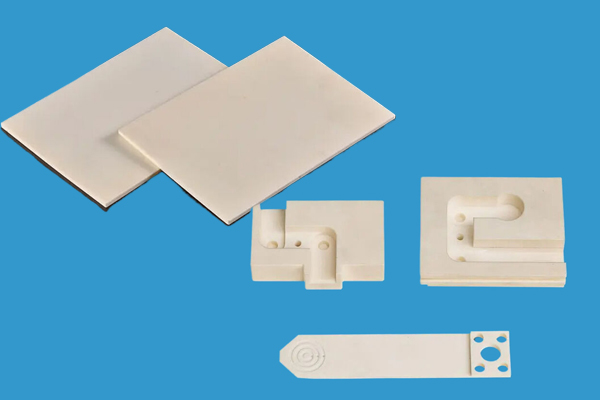

There are many types of ceramic plates. The conventional ceramic plates on the market are square ceramic plates, circular ceramic cups, semi-circular ceramic plates, ring ceramic plates, etc. At the same time, according to the way of use, ceramic plates have ceramic inserts, ceramic gaskets, ceramic protection plates, ceramic base plates, ceramic base plates, ceramic processing plates, etc.

Optional materials are available:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· Zirconia (ZrO2 TTZ /YTZP/ZDY)...

Size parameter of ceramic substrate plate

Shape: Rectangle, square, circle, semicircle, irregular, hole, customizable

Sizes: The thinnest thickness is 0.05mm, the max width is 550mm

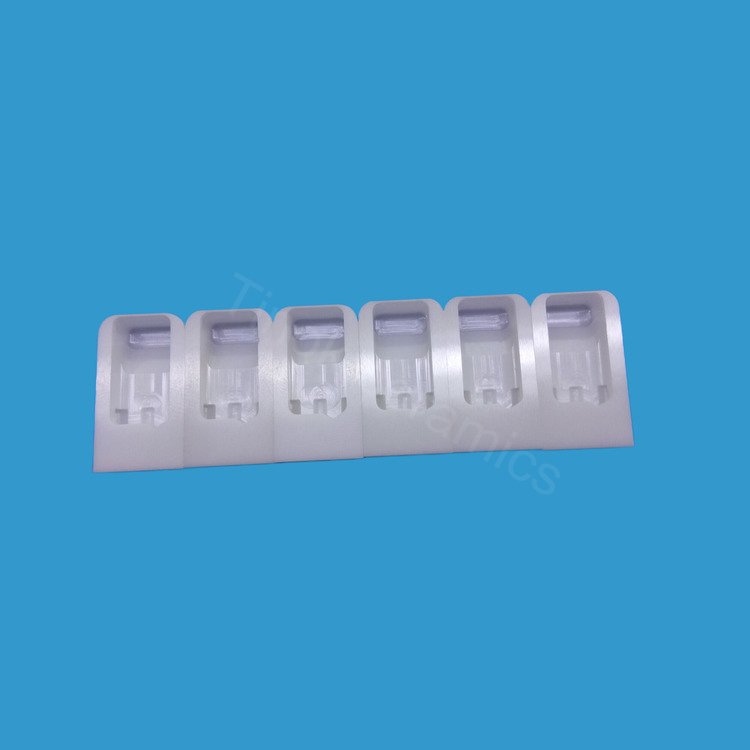

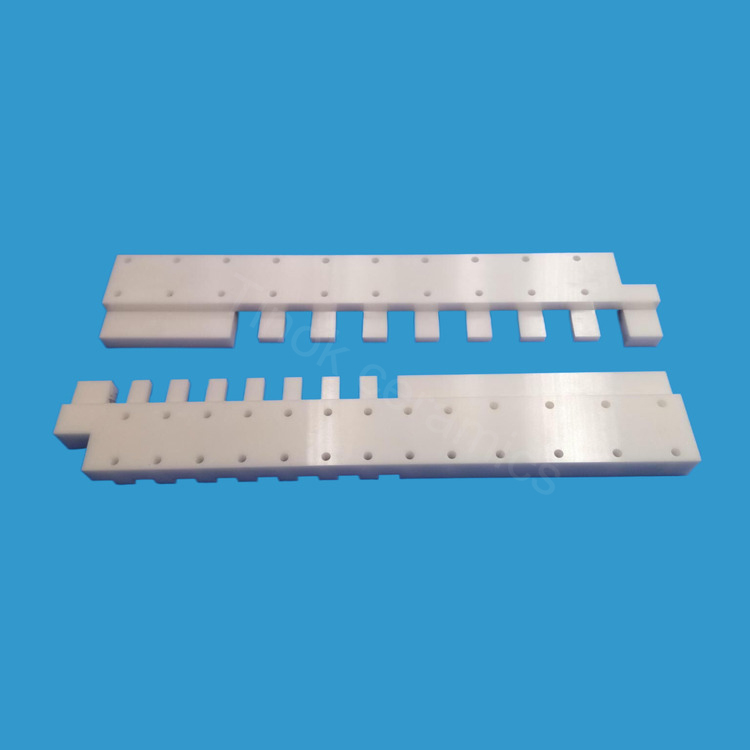

Processing service of ceramic substrate plate

The processing of ceramic plates is generally processed according to customer's customized requirements. Because each industry and each equipment use different parameters for ceramic plates, the process of custom processing is also different.

Ceramic plate surface processing modeling technology, with a variety of models of large water grinding, surface grinding, end grinding, double-sided grinding and other types of ceramic surface processing equipment, machining parts size tolerance up to 0.001, flatness up to 0.001, parallelism up to 0.001, perpendicularity up to 0.001, can be customized.

Suitable equipment, polishing fluid and brightening fluid can be selected according to the finish requirements of different parts. The highest finish can reach mirror, which can be customized on demand.

Ceramic substrate plate features

- 1.High hardness: the hardness of ceramic plate is very high, and its Rockwell hardness is HRA80-90, which far exceeds the wear resistance of wear-resistant steel and stainless steel.

- 2. High melting point: the melting point of alumina is as high as 1700 degrees, which makes the ceramic plate can work for a long time in a high temperature environment without being affected, and has good high temperature resistance.

- 3. Excellent mechanical strength: alumina ceramic plate has good conductivity and mechanical strength, can withstand greater pressure and impact force, to ensure its stability and reliability in the process of use.

- 4. Chemical resistance: Ceramic plate has strong chemical resistance and can work stably in various corrosive media.

- 5. Smooth surface: The surface of the ceramic plate is smooth, and the friction coefficient is small, which makes it have good wear resistance and corrosion resistance during use.

Application of ceramic substrate plate

- 1. Machinery industry: Ceramic plates are widely used in machinery industry, such as the manufacture of high-speed cutting tools, bearings, valves and seals. Due to its high hardness and wear resistance, it can effectively extend the service life of mechanical equipment and improve production efficiency.

- 2. Power industry: Ceramic plates have a variety of applications in the power industry, and can be used as insulation materials, bases for electronic components and substrates for circuit boards. Its high heat resistance and chemical stability make it able to withstand high temperature and corrosive gas erosion, to ensure the normal operation of power equipment.

- 3. Chemical industry: Ceramic plate has excellent corrosion resistance and chemical stability, so it is widely used in the chemical industry. It can be used as the lining material of reactors, pipelines and containers to resist the erosion of corrosive substances such as strong acids and alkali, so as to ensure the safety and stability of chemical processes.

- 4. Other fields: Ceramic plates can also be used in the petroleum industry, metallurgical industry and medical equipment and other fields. For example, in the petroleum industry, it can be used as an oil well repair material and an oil storage tank lining material, with good weather resistance and oil corrosion resistance.

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.