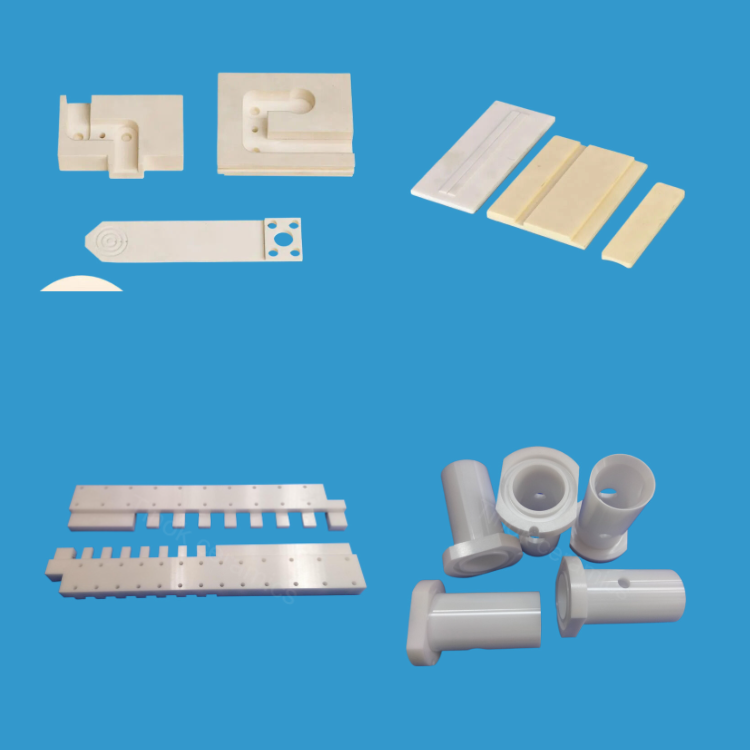

How to machining arc groove for alumina ceramic plate parts

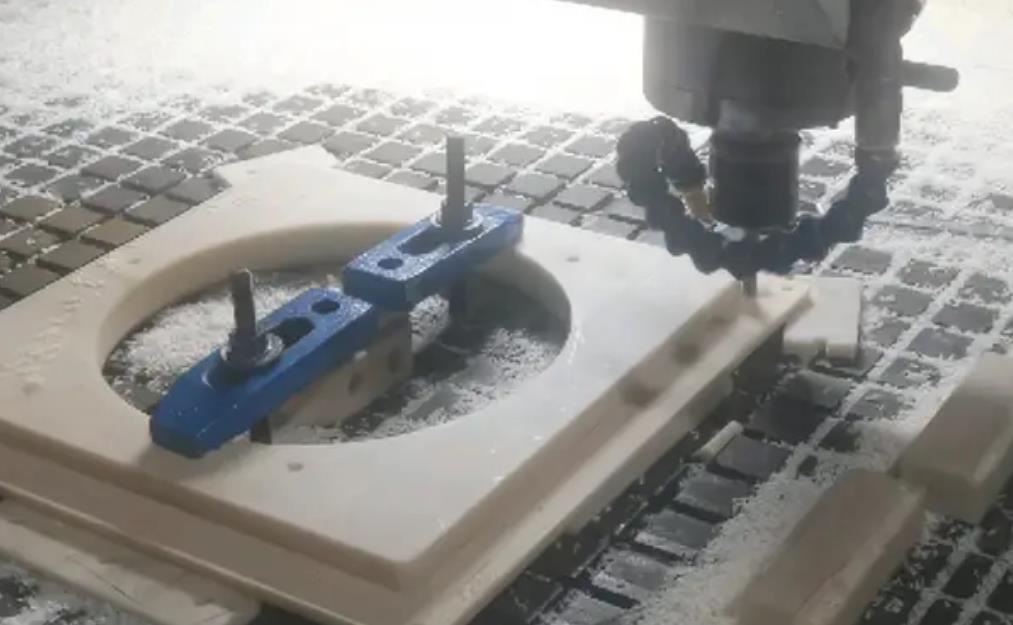

First, milling machining alumina ceramic plate arc groove

Milling method is one of the most commonly used arc groove machining methods for alumina ceramic plates, and its steps are as follows:

1. First of all, select the appropriate machining parameters, including cutting speed, feed rate and cutting depth.

2. Determine the position and path of the tool, and pay attention to avoid collision between the tool and the surface of the alumina ceramic plate.

3. Start milling, milling in accordance with the predetermined path until the desired groove width and depth are reached.

Second, drilling machining alumina ceramic plate arc groove

The drilling method is suitable for circular grooves with small diameters, and the steps are as follows:

1. First, select the appropriate drill bit, the diameter should be half the width of the desired groove.

2. Determine the drilling position and depth to avoid drilling into the alumina ceramic plate.

3. Drill holes until they reach the required depth.

4. Expand the width of the slot by vibration or rotation until the desired size is reached.

Third, stamping machining alumina ceramic plate arc groove

The stamping method is suitable for mass machining and circular grooves with large slot width, and the steps are as follows:

1. First of all, choose the right mold, including punch, mold seat, etc.

2. Fix the alumina ceramic plate on the mold to ensure the gap between the alumina ceramic plate and the mold in order to complete the punch rod.

3. Start punching rod until desired groove width and depth is reached.

Four. Precautions for machining arc grooves of alumina ceramic plates

1. Select the appropriate cutting speed, feed rate and cutting depth according to the alumina ceramic plate material and machining method, so as not to burn the alumina ceramic plate or seriously wear the tool.

2. When milling and drilling, care should be taken to avoid collision between the tool and the surface of the alumina ceramic plate, so as not to damage the alumina ceramic plate and the tool.

3. When stamping, attention should be paid to the accuracy and flatness of the mold, so as not to affect the machining effect and the quality of the alumina ceramic plate.

4. After machining, the tool and alumina ceramic plate should be cleaned in time to ensure the effect of the next machining.

In short, through reasonable machining methods and precautions, the machining of alumina ceramic plate parts circular groove can be efficiently completed, and the production efficiency and quality can be improved.