Are zirconia polycrystalline ceramics dentistry?

The zirconia used for dental implants is not a metal but a high-performance ceramic material.

I. Basic Properties of Zirconia

In dental implant materials, zirconia is gaining increasing attention and application. However, many people may have misunderstandings about whether zirconia is a metal. In fact, zirconia (ZrO₂) is not a metal but a high-performance ceramic material. It has extremely high hardness, excellent wear resistance, and chemical stability, which make it have a wide application prospect in the field of dental restoration.

II. Application of Zirconia in Dentistry

Due to its high hardness and wear resistance, zirconia is widely used in the production of dental restorations, such as dental crowns and dental bridges. Compared with traditional metal materials, zirconia ceramics have better aesthetics and biocompatibility. Moreover, its color is similar to that of natural teeth, which can meet patients' demands for aesthetics. Therefore, more and more patients and dentists choose to use zirconia as dental restoration materials.

III. Differences between Zirconia and Metal

Although zirconia exhibits similar metal-like characteristics in some aspects, such as high hardness and wear resistance, it has significant differences in essence. Metals are conductors, while zirconia is an insulator. Additionally, metals have ductility and can be shaped into various forms, while zirconia, due to its ceramic properties, has higher brittleness. These differences make zirconia and metal have their own advantages and limitations in dental applications.

The Characteristics and Applications of Zirconia Polycrystalline Structure

Zirconia polycrystalline structure, as a high-performance ceramic material, has demonstrated its unique advantages and broad application prospects in various fields in recent years.

I. Basic Characteristics of Zirconia Polycrystalline

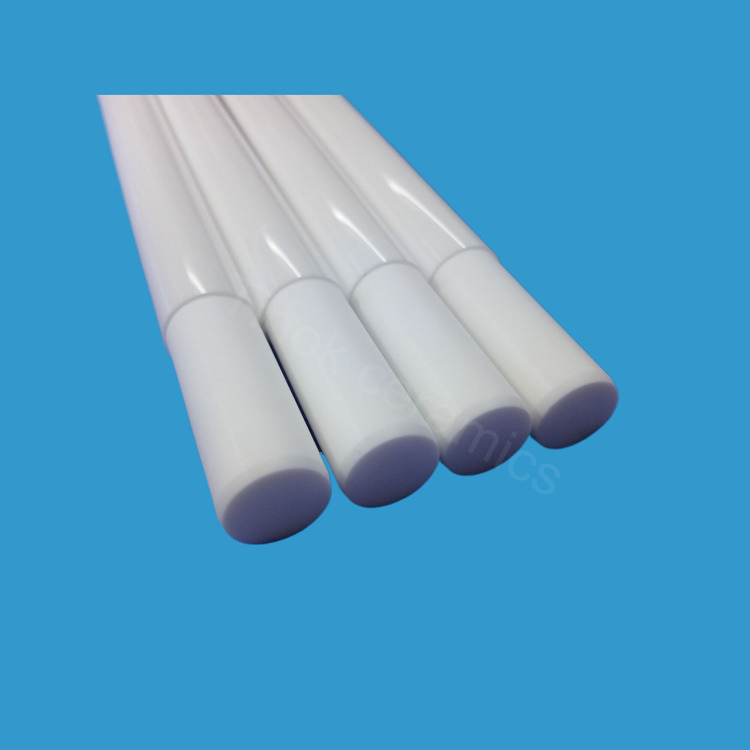

Zirconia polycrystalline is renowned for its high strength, high hardness, and corrosion resistance. This material has an extremely high melting point and can maintain stability in high-temperature environments, making it highly suitable for high-temperature processes and applications. Additionally, its chemical stability makes it an ideal choice for corrosion-resistant materials, especially in harsh environments such as acids and alkalis.

II. Application Areas of Zirconia Polycrystalline

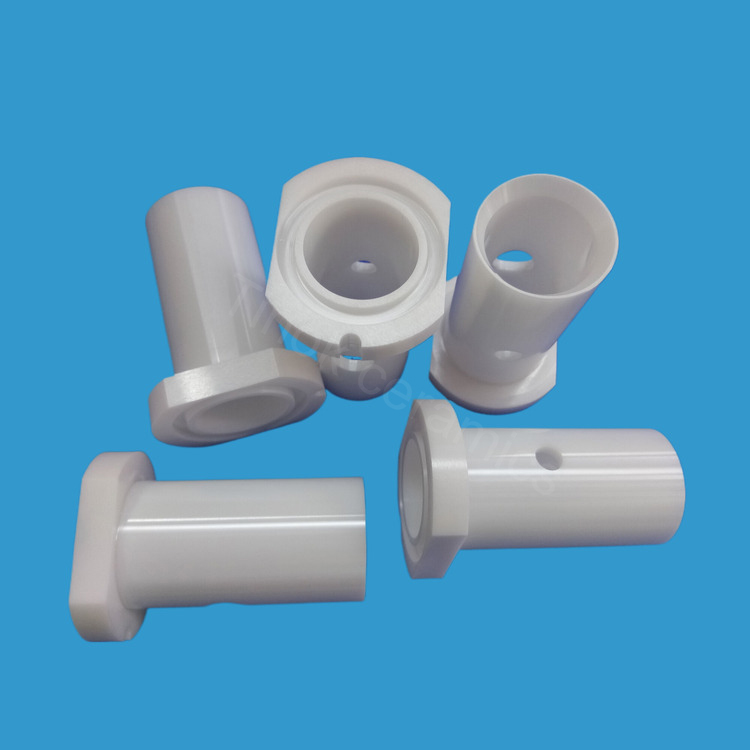

1. Ceramic Materials Field: Due to the high hardness and wear resistance of zirconia polycrystalline, it is widely used in the manufacturing of cutting tools, abrasives, and ceramic parts. These products not only have a long lifespan but also remain stable in high-temperature and corrosive environments.

2. Biomedical Field: Zirconia polycrystalline's biocompatibility makes it an ideal material for dental implants and bone implants. Its high strength and corrosion resistance ensure the long-term stability and safety of the implants.

3. Engineering Field: In the aerospace, automotive, and energy industries, zirconia polycrystalline is used as thermal barrier coatings and wear-resistant coatings to improve the performance and lifespan of mechanical components.