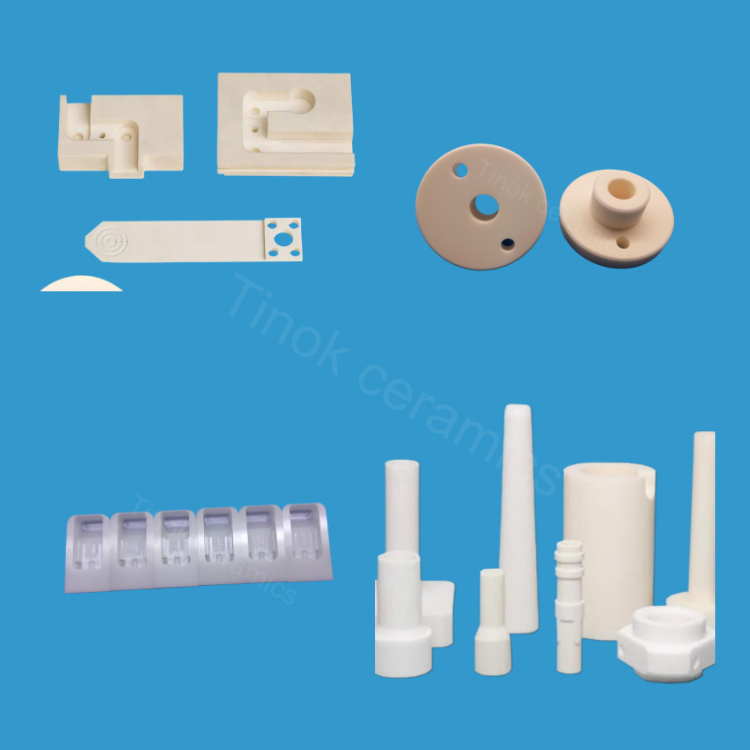

Precision ceramic parts CNC machining ceramic parts center fillet programming guide

First, the principle of processing ceramic parts center rounding and chamfering

The center fillet and fillet of ceramic parts are processed by the milling tool on the CNC machining center, and the edges of the ceramic parts are converted into fillets or fillets. For the processing of ceramic parts, there are generally three ways:

1. Cutting method: The edges of rounded corners of ceramic parts are cut flat, and then chamfered.

2. Two-section cutting method: cut a section along two edges respectively, and then connect the edges of the two sections of cutting.

3. Multi-section cutting method: the edge of the chamfer of the ceramic part is cut several times along the edge, so that the internal Angle of the original right Angle is gradually reduced, and the final corner is formed.

Second, the programming method of the center fillet and chamfer of the machining ceramic parts

The programming of the center fillet of ceramic parts is a very important part in the whole process of ceramic parts processing. The following is the programming method for the fillet of ceramic parts:

1. Choose the right tool: It should be considered according to the hardness, processing amount and processing quality requirements of ceramic parts.

2. Calculate the processing amount: calculate the processing amount according to the drawing and size requirements of the ceramic parts, determine the coordinate system of the processing process of the ceramic parts, and use the computer to write the processing program.

3. Program setting: According to the requirements of ceramic parts processing, set the parameters such as rounded radius and chamfer Angle in the processing program.

4. Set processing parameters: such as feed speed, return speed, cutting depth, etc.

5. Processing: ceramic parts are rounded and chamfered on the machining center.

Third, precautions

When machining the center fillet of ceramic parts, the following points need to be noted:

1. The selection of cutting tools and the fixing of cutting tools: the appropriate cutting tools should be selected according to the needs of processing ceramic parts, and ensure that they are firmly fixed.

2. Ensure the safety of the processing of ceramic parts: the operator should ensure the safety of processing and observe the wear of the cutting edge at any time.

3. Control processing parameters: the processing parameters of ceramic parts should be controlled during processing to avoid excessive wear or too fast damage to the cutting edge.

4. Processing quality requirements: to ensure that the products processed by ceramic parts can meet the processing quality requirements.

In short, machining ceramic parts center fillet is a very important process and technology, we need to try and sum up experience many times in practice, in order to achieve the ideal effect.