Can metals be welded together with ceramics

When ceramics are used in circuits, they must first be metallized, that is, a metal film that is firmly bonded to the ceramic and not easily melted is applied to the surface of the ceramic to make it conductive. Then, it is connected to the metal lead or other metal conductive layers through a welding process to form a whole. The most crucial step in the ceramic-metal sealing process is metallization, and its quality affects the final sealing effect. Ceramic engraving and milling machines are CNC machine tools with high technological content and high precision. Ceramic engraving and milling machines can process various industrial ceramic materials, such as alumina ceramics, zirconia ceramics, beryllium oxide ceramics, aluminum nitride ceramics, silicon nitride ceramics, etc. They are used to make various special-shaped and structural parts as required by the drawings. For the drilling, slotting, thread processing and micro-hole processing of industrial ceramic materials, ceramic-specific engraving and milling machines can be used for rapid processing. The ceramic-specific engraving and milling machine operates stably and reliably, with high processing quality and precision, low failure rate, low production cost, high production efficiency, and simple, convenient and safe operation. All parts have undergone high-precision grinding processing, ensuring high precision and long service life.

The difficulties in welding ceramics and metals

1.The linear expansion coefficient of ceramics is small, while that of metals is relatively large, which leads to joint cracking. Generally, the thermal stress problem of the metal intermediate layer should be well handled.

2. Ceramics themselves have a low thermal conductivity and weak resistance to thermal shock. When welding, minimize the temperature gradient at the welding site and its surroundings as much as possible, and control the cooling rate after welding.

Precision processing of ceramics

3. Most ceramics have poor electrical conductivity or even do not conduct electricity at all, making it very difficult to use electric welding methods.

4. Due to the stable electronic coordination of ceramic materials, it is not very possible to connect metals with ceramics. Ceramic metallization treatment or brazing with active brazing filler metal is required.

5. As most ceramic materials are covalent crystals, they are not prone to deformation and often suffer from brittle fracture. At present, most of the welding is carried out by using the intermediate layer to lower the welding temperature and the indirect diffusion method.

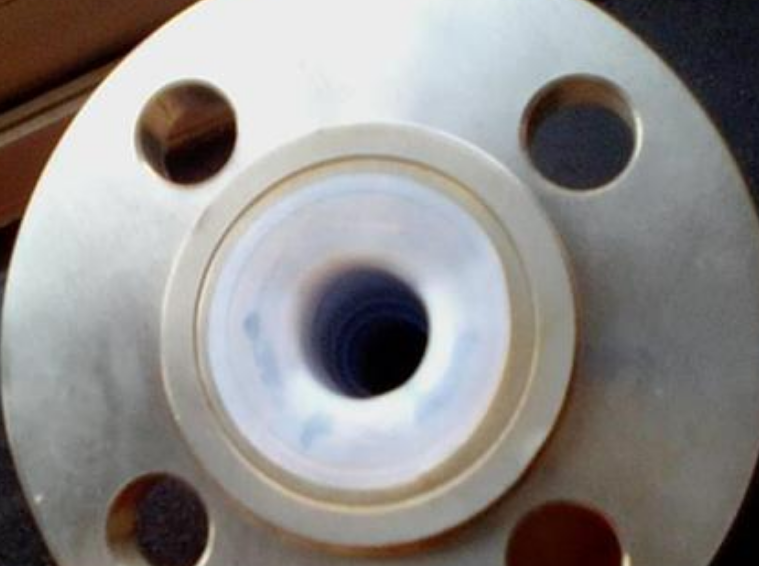

6. The structural design of ceramic and metal welding is different from that of ordinary welding. It is generally divided into flat sealing structure, sleeve sealing structure, needle sealing structure and pair sealing structure, among which sleeve sealing structure has the best effect. The manufacturing requirements for these joint structures are all very high.

The most commonly used connection technique: brazing

Brazing, a welding technique, hinges on a filler metal with a melting point lower than that of the base metal. It melts the filler metal at a temperature slightly higher than its melting point. The molten filler metal not only wets the surface of the materials to be joined, but also fills the gap between the joints, achieving the mutual diffusion of elements between the base material and the filler metal, thus completing the connection. This technology is particularly suitable for welding dissimilar materials with significant differences in physical and chemical properties, such as ceramics and metals. Its advantages lie in its simple operation, high connection strength, and suitability for extreme environments such as high temperature and high pressure.

However, the brazing of ceramics and metals faces two major challenges. The first issue is wettability. Since the wettability between metals and ceramics is often poor, or even non-wettability exists, measures need to be taken to improve the wettability of the brazing filler metal to the ceramic surface. This is usually achieved by metallizing the ceramic surface or adding active metal elements (such as Ti, Zr, Hf, V) to the brazing filler metal.

Ceramic metallization treatment, also known as the two-step method or indirect brazing method, mainly includes techniques such as Mo-Mn method, ion implantation method, vapor deposition method and chemical coating. This method first metallizes the ceramic surface and then completes the connection by conventional brazing. The core lies in converting the wettability of metal brazing filler metals to ceramics into wettability to metal coatings, thereby significantly enhancing the wettability effect. However, it should be noted that this method is rather complicated to operate and has a long cycle.

Another method is to add active metal elements to the brazing filler metal, which is also known as active brazing method, one-step method or direct brazing method. This method shows significant advantages in the connection of dissimilar materials between ceramics and metals. During the brazing process, active elements in the liquid brazing filler metal, such as Ti, Zr, V, Hf, etc., react with the ceramic, thereby improving the wettability of the brazing filler metal on the ceramic. These active elements react with the ceramic surface to form a compound reaction layer composed of the two, which has a structure and properties similar to those of metals, thereby achieving the metallurgical connection between ceramics and metals.

The wetting conditions of liquid AgCu and AgCu-5Ti (mass fraction) on the surface of Ti3SiC2 ceramics are illustrated. It can be seen from this that the addition of Ti element significantly reduces the wetting Angle. In addition, the residual stress problem caused by the difference in expansion coefficients between metals and ceramics should not be ignored either, as it may lead to insufficient joint strength. To address this issue, during the brazing process of ceramics and metals, methods such as adding special intermediate layers or using composite brazing filler metals are usually adopted to effectively alleviate residual stress and thereby enhance the overall strength of the joint.

Ceramic/metal intermediate layer brazing structure

The intermediate layer method is an effective way to alleviate the residual stress between ceramics and metals. It achieves this goal by introducing a buffer layer with a moderate coefficient of thermal expansion and elastic modulus between the two. This buffer layer can absorb part of the stress, thereby reducing the influence on the strength of the joint. The commonly used intermediate layer materials can be classified into three major categories: soft, hard and soft/hard composite. Soft intermediate layers, such as Cu, Ni, Al and other soft metals, release stress through their plastic deformation or creep. Hard intermediate layers, such as metals like W and Mo, have a relatively low coefficient of thermal expansion, similar to that of ceramics, and thus can effectively relieve stress. The soft/hard composite intermediate layer combines the advantages of both, usually consisting of a soft metal layer, a hard metal layer and a filler metal layer, and better cope with stress through its gradient change characteristic.

In addition, the composite brazing filler metal method is also a practical technique. It further enhances the strength of the joint by directly adding or in-situ generating reinforcing phases in the filler metal, such as C fibers, ceramic particles, metal particles or TiB whiskers, etc. These reinforcing phases can effectively disperse and alleviate residual stress, thereby enhancing the stability of the overall structure.

Ceramic-metal connections show important applications in multiple fields:

(1) Medical field

Bioceramic materials have been widely used in the medical field due to their excellent biocompatibility and antibacterial properties, such as bioceramic scaffolds, synthetic bones and artificial teeth. Meanwhile, metals such as titanium, titanium alloys and cobalt-based alloys also play an important role in dental, orthopedic and medical equipment. The application of ceramic-metal connections in the medical field is particularly important because bimetallic materials may generate metal wear particles that are detrimental to health during the application process. This problem can be effectively solved by connecting ceramic materials at the friction points, such as the connection application between metal Ti and Al2O3 ceramics.

(2) Power electronics field

In today's industrial age, electrical energy has become an indispensable source of energy, and ceramic-metal connections also play a crucial role in the field of power applications. Insulated Gate bipolar Transistor (IGBT), as a new type of power control device, is widely used in multiple fields such as mobile phones and high-speed railways. The active metal brazing method has been successfully applied to the brazing connection of IGBT modules with Si3N4 ceramic /Cu and AlN/Cu, which are mostly used in the manufacturing of IGBTs. In addition, as a key component for high-voltage power control, the vacuum switch tube is composed of ceramic and metal connections. The connection quality directly affects the vacuum degree of the vacuum tube and the power control effect. The brazing connection of Al2O3 ceramic tubes with metals (such as stainless steel, Cu) demonstrates excellent air tightness and joint performance in this aspect.

(3) Automotive field

Ceramic materials have also been widely applied in the automotive field. Engine valves need to have the characteristics of high-temperature resistance and wear resistance. Ceramic materials have a low specific gravity, and when applied to valves, they can increase the engine speed. For instance, Si3N4 ceramic joints have been successfully applied in this field. Furthermore, the valve toutings of diesel engines need to rub against the cams at a high frequency, which also involves the ceramic-metal connection technology.

(4) Solid fuel cells

Solid oxide fuel cells are one of the most promising batteries in the future. Its ceramic-metal composite structure composed of electrolyte, positive electrode and negative electrode bears a heavy load during operation. Therefore, ceramic-metal joints are required not only to have load-bearing capacity and air tightness, but also to have excellent oxidation resistance. The commonly used materials mainly include stainless steel and YSZ, etc.