Ceramic plunger or ceramic spray plunger which performance is better?

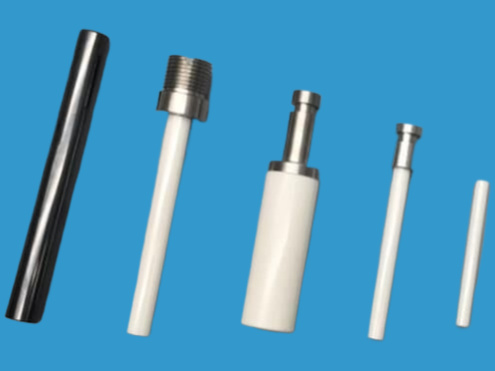

To know which is more suitable for the plunger pump, we should first understand the difference between the ceramic plunger and the ceramic spray plunger and their basic properties. Although they look very similar, they are actually very different, and different manufacturing processes also lead to different performance effects of the products.

Ceramic plungers are divided into many types, but different ceramic plungers have different roles, what kind of ceramic plunger should we choose, or what kind of ceramic plunger should we use on a machine, this is a very important issue, let's discuss the ceramic plunger and ceramic spray plunger which is more suitable for the plunger pump, for the ceramic plunger, I believe that we have a certain understanding, the basic performance of the ceramic plunger is dependent on the performance of the ceramic used, ceramic high temperature resistance, wear resistance, is a good material to use. However, in order to know which is more suitable for the plunger pump, we should first understand the difference between the ceramic plunger and the ceramic spray plunger and their basic properties. Although they look very similar, they are actually very different, and different manufacturing processes also lead to different performance effects of the products.

When we choose which is more suitable for the plunger pump, we must first consider the working environment of the plunger pump, and what kind of products are needed. Only when we know the production environment in advance, can we know what kind of products should be selected as parts for the machine.

The difference between ceramic spray and ceramic plunger

1, production process: ceramic spraying is a surface treatment technology, the powder ceramic glaze sprayed on the metal surface, after high temperature sintering, and ceramic is the use of traditional ceramic process, through the process of molding, drying, sintering and other production.

2, material composition: ceramic glaze is mainly composed of aluminum silicate, magnesium oxide, sodium oxide, alumina and sodium chloride and other substances, while ceramics are mainly composed of clay, feldspar and quartz and other natural minerals mixed.

Material characteristics

1. Ceramic plunger

Ceramic plunger usually adopts high purity alumina ceramic, the material has the advantages of high hardness, high wear resistance, high corrosion resistance and high mechanical strength, while its low coefficient of thermal expansion, low density, poor thermal conductivity, easy processing and forming, making it an ideal material for manufacturing precision mechanical components.

2. Spray ceramic

ceramic spraying is to coat the metal surface with a high melting point, high hardness ceramic coating to improve its corrosion resistance, wear resistance, insulation and reduce thermal diffusion coefficient and other properties, usually used materials including alumina, zirconia, silicon carbide and so on.

Application field

1. Ceramic plunger

Ceramic plungers are widely used in high-precision mechanical equipment, such as precision instruments, pressure control components and hydraulic valves, and their high mechanical strength and corrosion resistance can operate statically in a variety of harsh environments.

2. Spray ceramic

ceramic spraying is mainly used in the field of protective coating, such as the surface coating of automotive engines, industrial machinery, etc., to protect it from corrosion and wear, but also to increase its insulation and mechanical strength.

The production process

1. Ceramic plunger

The ceramic plunger usually adopts the injection molding process, which has high processing precision, high consistency and stability, and relatively high production cost.

2. Spray ceramic

ceramic spraying adopts flame spraying, plasma spraying, arc spraying and other processes, which has wide adaptability and low production cost.

Other differences

1. Performance comparison

The wear resistance and corrosion resistance of ceramic plunger are stronger than that of ceramic spray, but the relative price is also higher. ceramic spraying is relatively cheap, but difficult to manufacture into complex shapes, the scope of application is limited.

2.Security

The high hardness of the ceramic plunger makes it prone to debris, which may cause damage to machinery or personal safety. ceramic spraying is relatively safe, and there is no problem of debris falling off.

Ceramic plungers have the following characteristics:

(1) Ceramic plunger using high-performance technology ceramic material, with high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties. Ensure reliable material performance.

(2) The micro-porous structure obtained by the unique processing means of the ceramic plunger working face has a self-lubricating effect, which changes the sliding friction and lubrication mechanism of the traditional plunger pump.

(3) The surface of the inner cavity adopts a fluid structure, without dead corners and grooves. The surface of the inner cavity and the surface of the plunger are processed to the mirror by advanced high-precision internal and external cylindrical grinding machine, and the external surface is polished by vibration, which is convenient for cleaning and disinfection.

(4) The pump body structure is precisely sealed with the product structure for easy disassembly.

(5) This kind of product has been corrosion resistance, acid and alkali resistance safety performance test, its indicators have reached the international advanced level.

Features of ceramic spray piston pump

1. Corrosion resistance: ceramic spray coating can effectively prevent chemical corrosion and wear inside the pump body. At the same time, brass itself also has good corrosion resistance and can adapt to the transportation of most media.

2. High strength: The material of the brass plunger pump has a high strength, especially in the case of high temperature and high pressure, and can show its high strength characteristics.

3. High efficiency: ceramic spray brass plunger pump can achieve high efficiency transport, and can adjust the output of different flows. This is also one of the reasons why it is widely used in industrial production.

It can be seen that the ceramic plunger has better performance than the ceramic spray plunger, and is more suitable for the operation requirements and working environment of the injection pump and plunger pump.