Does the strength of a ceramic part depend on its size? why?

The strength of ceramic components is indeed related to their size, mainly due to the effects of porosity and grain size.

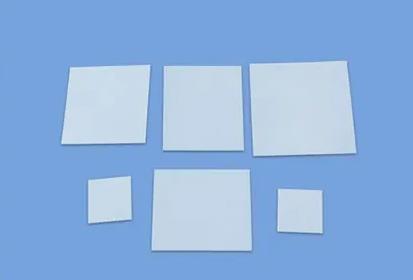

Size effect and porosity

Ceramic materials are difficult to achieve complete densification during sintering, and the remaining pores significantly reduce the actual strength. When the component size is reduced to the sub-micron level, the change in porosity has a magnified effect on strength. For example, if the porosity of alumina ceramics increases by 5%, its tensile strength decreases by 25%; if the porosity increases from 0% to 30%, the fracture strength will drop from 700 MPa to 100 MPa.

The influence of grain size

Fine grain structure can significantly enhance ceramic strength. Experiments show that the room temperature fracture strength is inversely proportional to the grain size (as per the formula ∝). The finer the grains, the higher the strength. In microforming, reducing the size may expose more pore defects, leading to a decrease in strength.

Theoretical strength comparison

The theoretical strength of ceramics is usually 1/50 to 1/500 of the actual strength, mainly due to manufacturing defects (such as pores, cracks) causing stress concentration. Although reducing the size may reduce the impact of defects, it is difficult to completely eliminate defects in actual production, so the strength is still constrained by size.

The strength of ceramic materials and its influencing factors

The strength of ceramic materials is one of the important mechanical properties of these materials. It determines the ability of the material to resist damage when subjected to external forces. The strength of ceramic materials is influenced by several factors:

1. Porosity: Porosity is a common defect in ceramic materials, which significantly reduces the strength of the material. The higher the porosity, the lower the strength of the ceramic material.

2. Grain size: Grain size has a significant impact on the strength of ceramic materials. Generally, the smaller the grain size, the higher the fracture strength of the material, as smaller grains help to hinder the propagation of cracks.

3. Properties of grain boundaries: The composition, nature, and quantity of grain boundaries have a significant influence on the strength of ceramic materials. Grain boundaries can effectively prevent the propagation of cracks.

4. Temperature: The strength of ceramic materials is greatly affected by temperature. At high temperatures, the strength of ceramic materials may decrease, but in some cases, they also exhibit certain plasticity.

5. Chemical composition of the material: Different ceramic materials, such as oxides, nitrides, borides, and carbides, have different inherent strengths due to the types and strengths of their chemical bonds.

6. Microstructure: The microstructure of ceramic materials, including grain boundaries, interface between phases, and microscopic defects, all have an impact on the strength of the material.

7. Composites: By adding a second phase, such as fibers or particles, to the ceramic matrix, the fracture toughness and strength of the ceramic can be improved.

8. Sintering process: The sintering process has a significant impact on the density and microstructure of ceramic materials, thereby affecting the strength of the material.

9. Heat treatment: Appropriate heat treatment can reduce residual stress in ceramics, improving the strength of the material.

10. Surface treatment: Surface treatment, such as polishing or coating, can reduce surface defects and improve the surface strength of the material.

Understanding these influencing factors is crucial for designing and developing ceramic materials with the desired strength characteristics. By precisely controlling these factors, the performance of ceramic materials can be significantly improved, thereby playing a key role in various engineering applications.