Dry forming process of zirconia ceramics

Dry forming of zirconia ceramics uses powder materials, that is a mixture of solid particles and air, as raw materials for forming. Dry forming can be further divided into dry pressing forming and isostatic pressing forming. Due to the different pressure application methods, the quality of the green bodies prepared by these two forming methods varies greatly.

The so-called dry molding process uses powder materials, that is, a mixture of solid particles and air, as raw materials for molding. To reduce friction and increase the strength of the formed green body, the powder may contain a small amount of liquid wrapped around the particles, such as pesticides, binders, lubricants, etc. In order to densify, it is usually necessary to expel the air between the particles as much as possible. Generally, the method of pressurization is adopted to force the particles to approach each other and expel air. According to the way pressure is applied during the forming process. The dry forming of zirconia ceramics can be further divided into dry pressing forming and isostatic pressing forming. Due to the different pressure application methods, the quality of the green bodies prepared by these two forming methods varies greatly.

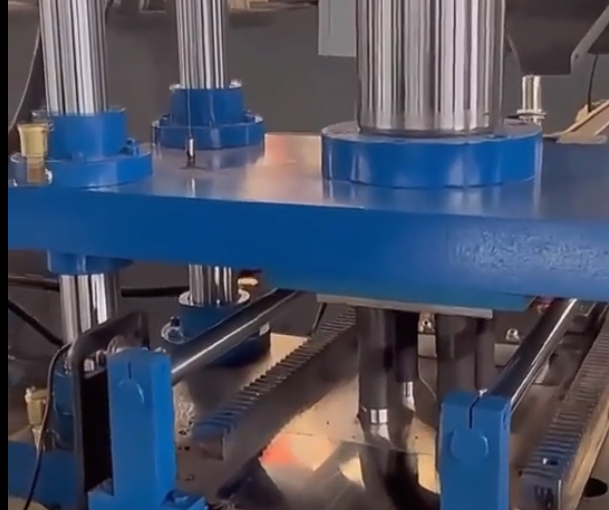

Dry pressing, also known as die pressing, is a process in which granulated powder is placed in a steel mold and pressurized on a press to form a green body of a certain shape. Dry pressing molding is commonly used in the production process of advanced ceramic solid materials: The characteristics of dry pressing molding are low binder content, generally 7%-8%, and it can be directly sintered without drying. It has many advantages such as simple production process, high efficiency, small green body shrinkage, and the ability to be automated in production. It can be widely used in the production of various functional ceramics and electronic components in the form of circular and thin sheets. It is especially suitable for pressing products of simple shapes with a height of 0.3-60mm and a diameter of 5-50mm. During dry pressing, parameters such as the pressing method, pressure, pressing speed and holding time have a significant impact on the density of the green body. Especially due to uneven pressure distribution, the internal density distribution of the green body is inconsistent, thereby affecting the performance.

Zirconia ceramics in dry pressing molding, the pressure application methods include unidirectional pressing and bidirectional pressing. Due to the different pressure application methods, the distribution and transmission of pressure within the mold also vary. When unidirectional suppression occurs, a distinct pressure gradient will emerge. The greater the pressure difference of the green body is, the greater the density of the green body is at the top. The density of the central part below is relatively low. This is mainly because when the pressure is transmitted to the billet through the press head, the particles of the comparison group in the billet layer close to the press head separate the fine particles and ultrafine particles in that layer, making them approach each other not only vertically but also horizontally. Then the indenter advances further, and the pressure is transmitted to the inner layer through the dense layer close to the indenter and gradually decreases. Part of the pressure is also transmitted to the mold wall from the pressure head. Therefore, the green body has different densities at different heights and cross-sections.

Do you want to know the process advantages of dry pressing zirconia ceramic plates?

Zirconia ceramic dry pressing forming is a forming method that uses pressure to press the dry powder blank of zirconia ceramic plates into a dense body in a mold. Due to the low moisture content and high pressure of the dry-pressed zirconia ceramic plate green body, the green body is relatively dense. Therefore, it can obtain zirconia ceramic plate green bodies with small shrinkage, accurate shape and no need for vigorous drying. Dry pressing of zirconia ceramic plates has been widely used in industrial ceramics and achieved good results.

The process advantages of dry pressing forming: The dry pressing forming process of zirconia ceramic plates is simple, with a large production volume of zirconia ceramic plates, few defects, and is convenient for mechanization. Therefore, it is quite suitable for forming simple and small-sized zirconia ceramic plate blanks. Zirconia ceramics are white and yellow or gray when containing impurities. They usually contain HfO2 and are not easy to separate.

Under normal pressure, pure ZrO2 has three crystal states. The production of zirconia ceramics requires the preparation of high-purity, well-dispersed, ultrafine particles and narrow particle size distribution powders. There are many methods for preparing ultrafine zirconia powders. The purification of zirconia mainly includes chlorination and thermal decomposition, alkali metal oxidation decomposition, lime melting, plasma arc, precipitation, colloid, hydrolysis, spray pyrolysis, etc.