Precision ceramic parts processing chamfer: technical and operational guidelines

Ceramic parts CNC engraving machine precision ceramic parts processing chamfer: technical and operational guidelines

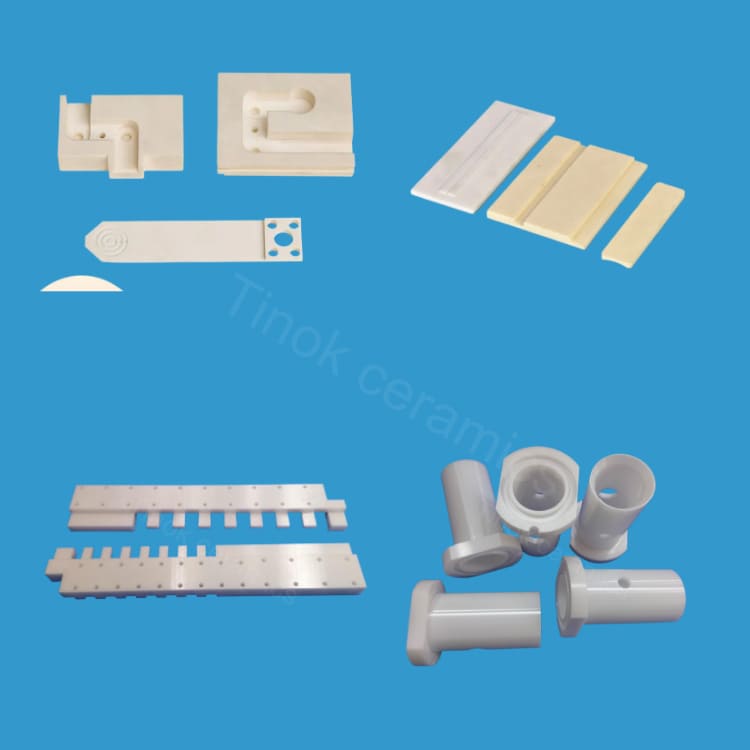

CNC engraving machine for ceramic parts can process precision ceramic accessories chamfer, its ceramic parts processing precision is high, high efficiency, widely used in various materials ceramic parts chamfer processing.

The basic concept and importance of chamfering of ceramic parts

Ceramic parts chamfering processing, that is, a certain Angle of the bevel is processed at the edge or hole of the ceramic parts to improve the beauty and performance of the ceramic parts. Chamfering can not only avoid stress concentration, improve the strength and stability of ceramic accessories, but also prevent scratching or scratching and improve the overall quality of the product. Therefore, chamfering has a very important position in the manufacturing industry.

CNC engraving machining advantages of ceramic parts chamfer

CNC engraving machine, as a high-precision machining equipment, has significant advantages in chamfer machining. First of all, CNC engraving machine can achieve high-precision chamfer processing to meet the needs of complex shapes and angles of various ceramic parts. Secondly, CNC engraving machining efficiency is high, can greatly improve the production efficiency. In addition, the CNC engraving machine also has the characteristics of simple operation and good processing stability, which makes the chamfer processing easier to achieve.

Method and step of NC engraving machining ceramic parts chamfer

1. Determine the processing requirements of ceramic parts: according to the material, size and chamfer requirements of ceramic parts, determine the appropriate processing parameters and tools.

2. Write ceramic parts processing program: Using CNC engraving machine programming software, write processing program according to ceramic parts drawings and processing requirements. The program should include key parameters such as tool path, machining speed and cutting depth.

3. Install ceramic accessories and tools: Place the ceramic accessories on the work table of the CNC engraving machine, and install the selected tool.

4. Run the processing program: start the CNC engraving machine and carry out the chamfer processing according to the written processing program. In the processing process, it is necessary to pay close attention to the processing state and adjust the processing parameters in time to ensure the processing quality.

5. Inspection and correction: After the processing is completed, the ceramic accessories are inspected to check whether the chamfer meets the requirements. If there is no compliance with the requirements, it is necessary to modify the processing procedures or processing parameters of ceramic parts and re-process.

CNC engraving machine machining ceramic parts chamfer precautions

1. Choose the right tool: Select the right tool according to the ceramic accessories material and chamfer requirements to ensure processing quality and efficiency.

2. Control cutting speed: Too fast cutting speed may lead to increased tool wear or a decline in the surface quality of ceramic parts, so it is necessary to choose the right cutting speed according to the characteristics of the material and the tool.

3. Safety protection during processing: In the process of processing, it is necessary to take safety protection measures, such as wearing protective glasses and gloves, to avoid accidental injuries.

In short, CNC engraving machine has unique advantages and application value in the processing of ceramic parts chamfer. By mastering the technical points and operating steps of CNC engraving machining ceramic parts chamfer, we can realize the chamfer processing of various materials and shapes of ceramic parts, and improve product quality and production efficiency.