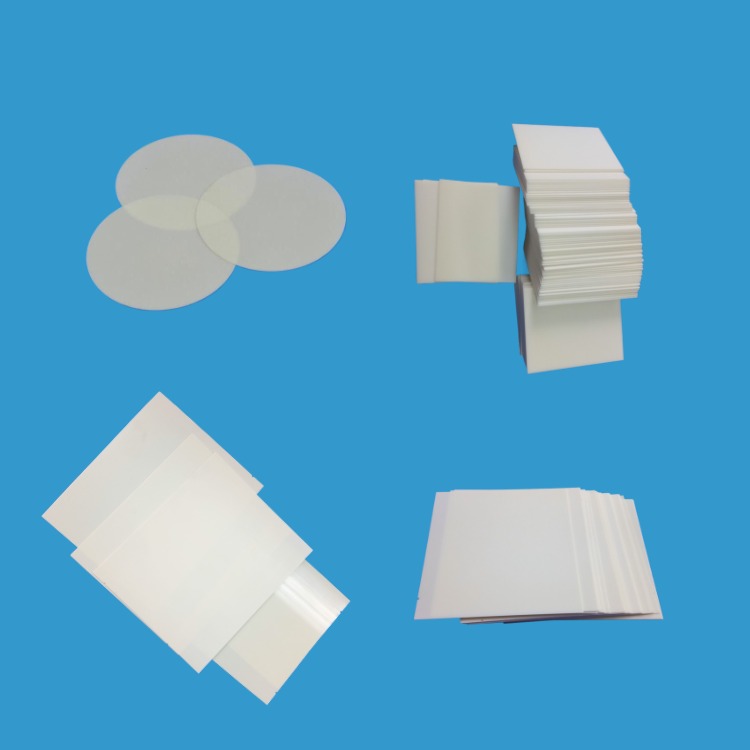

Precision polishing of alumina ceramic plate

Precision polishing of alumina ceramic plate is a key process, which plays a vital role in the surface treatment of ceramic plate.

This process is described in detail from three aspects: preparation, polishing steps, and the importance of precision polishing.

1, Preparation Before precision polishing of alumina ceramic plate, it is first necessary to check and prepare the equipment and tools.

Ensure that the functions of the polishing machine are normal, the polishing disc is complete and without damage, the polishing fluid is sufficient, and the appropriate polishing media and parameters need to be selected according to the alumina ceramic plate of different materials.

In addition, the operator should wear protective equipment to ensure safe production.

2, Polishing steps In the alumina ceramic plate precision polishing, first of all, the substrate to be polished is installed on the polishing machine polishing disc, adjust the speed of the polishing machine and polishing time.

Then, add the appropriate amount of polishing liquid according to the actual situation, start the polishing machine, and start the polishing operation.

In the polishing process, it is necessary to constantly observe the surface of the substrate and adjust the parameters of the polishing machine in time to ensure that the polishing effect meets the requirements.

The polished substrate is removed and cleaned to ensure that its surface finish is up to standard.

3, The importance of precision polishing The surface quality of the alumina ceramic plate directly affects the subsequent process and the quality of the final product.

Precision polishing, as a key part, can effectively remove burrs and defects on the surface of the substrate, improve its finish and flatness, and thus improve the reliability and stability of the entire process.

Moreover, precision polishing can also increase the corrosion resistance of the substrate, extend its service life, reduce production costs, and improve product quality and market competitiveness.

In general, the precision polishing of alumina ceramic plate is a crucial process, which needs to be operated in strict accordance with the operating procedures to ensure the stability and consistency of the polishing effect.

Only by doing a good job of precision polishing can we ensure that the quality and performance of the alumina ceramic plate meet the requirements and lay a solid foundation for the successful manufacturing of the final product.

It is hoped that through the above introduction, we can have a deeper understanding of alumina ceramic plate precision polishing and apply it in actual production.