What are structural ceramics?

Structural ceramics are commonly referred to as ceramics used in the manufacture of mechanical equipment and processing tools in various industrial sectors. At present, the most commonly used structural ceramics are alumina, silicon carbide, zirconia and silicon ammonia. Most of these ceramic materials are sintered with powder raw materials at a certain temperature and pressure. In the case of alumina ceramics, it is made by pressing and sintering extremely fine pure aluminum oxide powder. Under pressure and high temperature, the fine alumina particles are welded together to form a fine crystalline structure, and its atomic distance is very small. In this way, its binding force is much larger than other materials, even at high temperatures is much harder than the general material, so it has excellent wear resistance, but also has a strong corrosion resistance, is the ideal material for making processing tools.

Types of structural ceramics

In materials, there is a class of structural materials mainly made of various materials made of mechanical properties such as strength, hardness and toughness. Metal has been widely used as a structural material. However, because the metal is susceptible to corrosion, it is not resistant to oxidation at high temperatures and is not suitable for use at high temperatures. The appearance of high-temperature structural materials makes up for the weakness of metal materials. This kind of material can withstand high temperature, not afraid of oxidation, acid and alkali corrosion resistance, high hardness, wear resistance, low density and other advantages, as a high temperature structural material, very suitable.

1, alumina ceramics

Alumina ceramics (artificial corundum) is a promising high temperature structural material. Its melting point is very high, can be used as high-grade refractory materials, such as crucible, high temperature furnace tube. Using the advantages of alumina hardness, it is possible to manufacture corundum grinding machines used in the laboratory to grind materials with less hardness than it. With high purity raw materials, the use of advanced technology, can also make alumina ceramics transparent, can produce high-pressure sodium lamp tubes.

2. Silicon nitride ceramics

Silicon nitride ceramics Ceramic is also an important structural material, it is a kind of superhard substance, small density, itself has lubricity, and wear resistance, in addition to hydrofluoric acid, it does not react with other inorganic acids, corrosion resistance; It also resists oxidation at high temperatures. Moreover, it can also resist cold and thermal shock, heated to more than 1000 in the air, sharply cooled and then sharply heated, and will not crumble. It is silicon nitride that has such good characteristics that it is often used to manufacture mechanical components such as bearings, turbine blades, mechanical sealing rings, and permanent molds.

3, boron nitride ceramics, boron carbide ceramics

4. Artificial gems

The main components of ruby and sapphire are Al2O3 (corundum). The red color of rubies is due to a small amount of chromium compounds mixed with them; The blue color of sapphire is due to a small amount of titanium compounds mixed in it. In 1900, scientists used the method of melting alumina and adding a small amount of chromium oxide to produce a ruby with a mass of 2g-4g. It is now possible to produce rubies and sapphires as large as 10g.

Structural ceramics are ceramic materials used in various industrial fields for the manufacture of precision parts in advanced machinery and equipment, functional ceramics are a kind of spiritual materials, they can sense light, or distinguish smells, or can store information, can show special functions of ceramics.

Definition of structural ceramics and functional ceramics:

1. Structural ceramics refer to advanced high-tech ceramic products that mainly use their mechanical, thermal and partial chemical functions in the application. If the ceramics can be applied at high temperatures, they can be called high-temperature structural ceramics.

(2) Functional ceramics refer to advanced ceramic materials and products that are mainly used for their non-mechanical properties, and this class of materials has one or more functions.

Structural ceramics and functional ceramics similarities and differences:

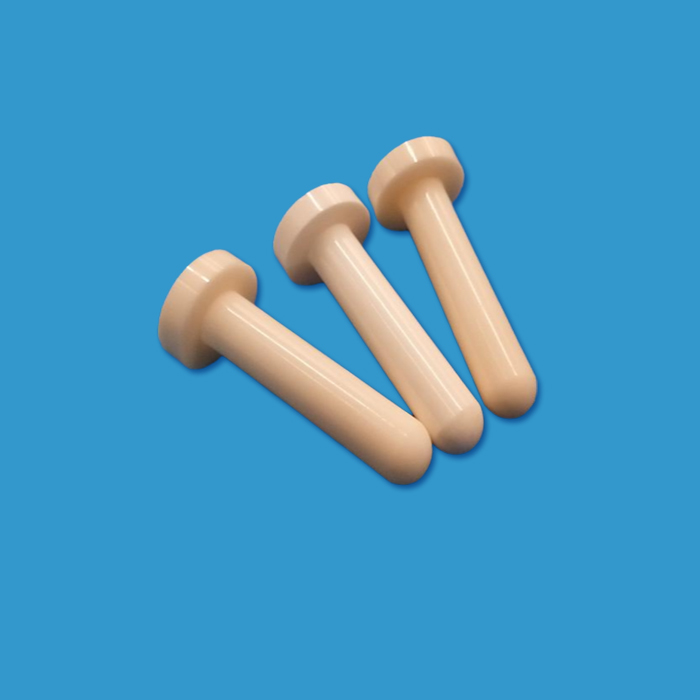

1. Structural ceramics: It can be designed by designers into a variety of styles and structures that can be processed according to the actual needs of equipment assembly, mainly used at high temperatures, also known as high temperature structural ceramics. This kind of ceramics has the advantages of high strength, high hardness, corrosion resistance, wear resistance and ablative resistance at high temperatures, and is an important material in the fields of space technology, military technology, atomic energy, industry and chemical equipment. There are many kinds of structural ceramics used in industry, such as: ceramic tube sleeve, ceramic center rod, ceramic roller, lithium battery ceramic pump, ceramic ring, ceramic plate, petrochemical ceramics, military ceramics and other industries are widely used.

(2) Functional ceramics: The use of ceramics for light, magnetic, electrical, sound, heat and other physical properties of the special function of the ceramic material is called functional ceramics. There are many kinds of functional ceramics with different uses. For example, according to the differences in the usual electrical properties, it can be made into semiconductor ceramics, dielectric ceramics, insulating ceramics, conductive ceramics and other electronic materials, which are used to make capacitors, high temperature and high frequency devices in the electronics industry.