What car parts are ceramic?

Ceramic materials have always been one of the materials widely used in all walks of life, and in the automotive car field, ceramic materials are also one of the more widely used materials. In the automotive car manufacturing process, in addition to common components such as wheels, brake pads and engines, ceramic materials have a wide range of other applications.

One. Engine components

1. Cylinder liner and piston ring

Ceramic materials can overcome the wear of metal materials, thermal expansion coefficient difference and other problems. It has excellent wear resistance, high temperature strength and low thermal expansion coefficient. Ceramic liner can reduce the heat loss of automotive car engines and increase fuel efficiency.

2. Valve

The main body of alumina ceramic valve chip is alumina ceramic and metal substrate, its strength and wear resistance are much better than ordinary cast iron and steel valve.

Two, brake system

Brake force is large, the use of high frequency, ceramic material hardness, thermal stability and corrosion resistance are in line with the use of automotive car brake system requirements. At present, the main components of the brake system are as follows:

1. Brake pads

Brake pads made of ceramic composite materials not only have a longer service life, but also do not produce a lot of dust and noise when braking.

2. Brake disc

The brake disc made of ceramic is lighter than the ordinary metal brake disc, the coefficient of thermal expansion is lower, the service life is longer, and the braking performance is better.

Three, the horn

The high-frequency characteristics of ceramic materials are very favorable for the manufacture of horns, and the high-frequency horns made of ceramic materials are not easy to be deformed, which can ensure the stability and high quality of the sound.

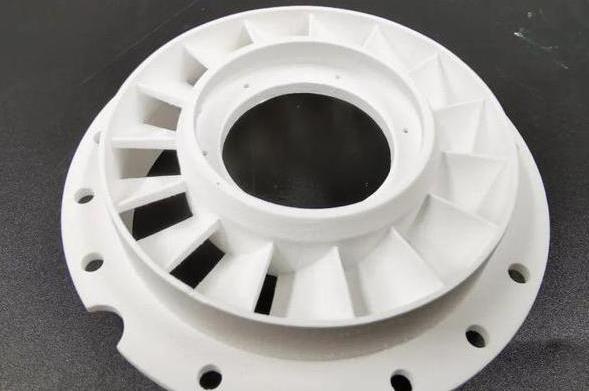

Four, turbocharger

Turbocharger is an important device to improve the power performance of automobiles. The application of ceramic materials can effectively reduce the heat loss and inertia loss, and improve the efficiency of turbocharger.

Five. Sensor

The sensor is the core of the automotive car electronic control system, and ceramic materials are widely used in vehicle sensors because of their excellent physical properties, such as oxygen sensors, pressure sensors, temperature sensors and so on.

automotive car ceramic connectors are made of inorganic non-metallic materials such as zirconia ceramics and yttrium oxide ceramics sintered, so compared with the alumina ceramics used in the past, the strength and high temperature resistance have been significantly improved, further enhancing its application effect in the automotive car field.

Some traditional materials made of automotive car engines, often have a serious problem of heat loss, in order to reduce this part of the loss, it is necessary to use good thermal insulation performance of zirconia ceramic materials around the combustion chamber for heat insulation, and then use exhaust gas turbocharger and power turbine to recover exhaust energy, so as to effectively improve the thermal efficiency of automotive car engines.

In addition, many of the equipment, parts and small equipment used in automobiles are also made of special ceramic materials. Such as electronic buzzer, ultrasonic oscillator, heat-absorbing glass, photocell, oil plug ring, oil water seal and so on. These automotive car products made of new special ceramic materials usually have high physical and chemical properties, such as impact resistance, wear resistance, corrosion resistance, high temperature resistance, light weight, and easy processing and production.

In general, ceramic materials are widely used in automotive car manufacturing, which can improve the heat resistance, corrosion resistance and wear resistance of automotive car parts, and play an important role in reducing vehicle fuel consumption and improving power performance.