Alumina ceramics have high wear resistance

Alumina ceramic is a kind of ceramic material mainly composed of alumina (Al2O3), which has the characteristics of high hardness, high strength and high wear resistance. This paper will introduce the high wear resistance of alumina ceramics in detail, and discuss its application in various fields.

Alumina ceramics have a very high hardness, its Mohs hardness can reach 9. This makes alumina ceramics excellent in terms of wear resistance. In contrast, traditional ceramic materials such as porcelain Mohs hardness is only 6-7, diamond and silicon carbide are 10 and 9.5, respectively. High hardness enables alumina ceramics to resist external scratches and wear on their surface, thereby extending their service life.

Alumina ceramics are composed of uniform and dense microcrystalline particles without pores and cracks between the particles. This microstructure guarantees high wear resistance of alumina ceramics. The dense structure makes the alumina ceramics effectively resist the erosion of external media and particles, and it is not easy to produce surface wear and spalling.

Alumina ceramics have high wear resistance. Alumina ceramic is a kind of high hardness, high strength ceramic material, its hardness is close to diamond, second only to diamond. This makes alumina ceramics have excellent properties in terms of friction, wear and grinding.

The wear resistance of alumina ceramics is mainly reflected in the following aspects:

High hardness: The hardness of alumina ceramics is very high, and it can resist scratches and wear of external objects.

Excellent wear resistance: Alumina ceramics have good wear resistance and can be used for a long time without damage under harsh conditions such as high speed, high temperature and high pressure.

Low coefficient of friction: Alumina ceramics have a low coefficient of friction, which can reduce the friction loss when in contact with other materials.

Corrosion resistance: alumina ceramics have good corrosion resistance, can resist acid, alkali and other chemical substances erosion, not easy to be damaged by corrosion.

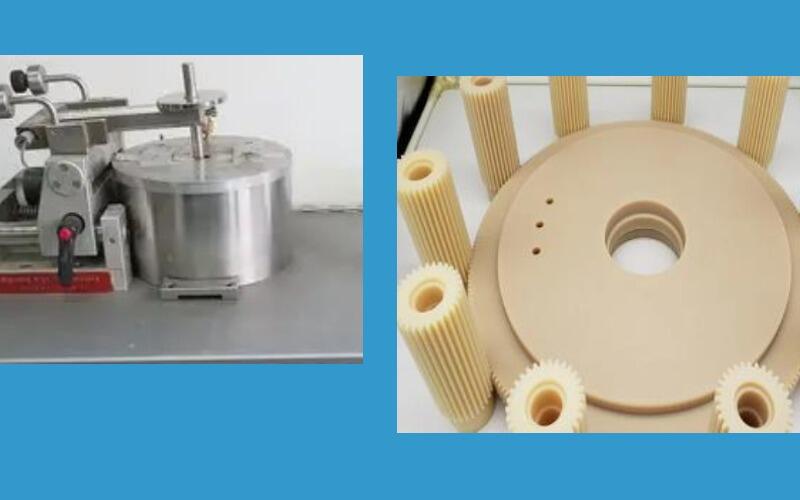

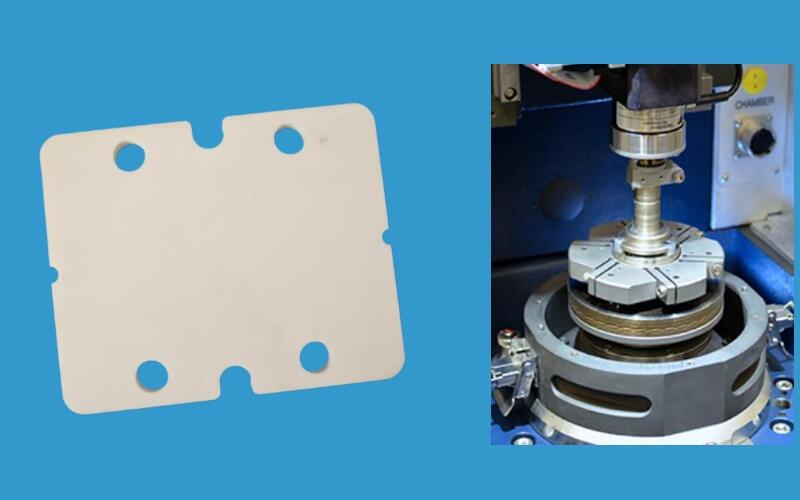

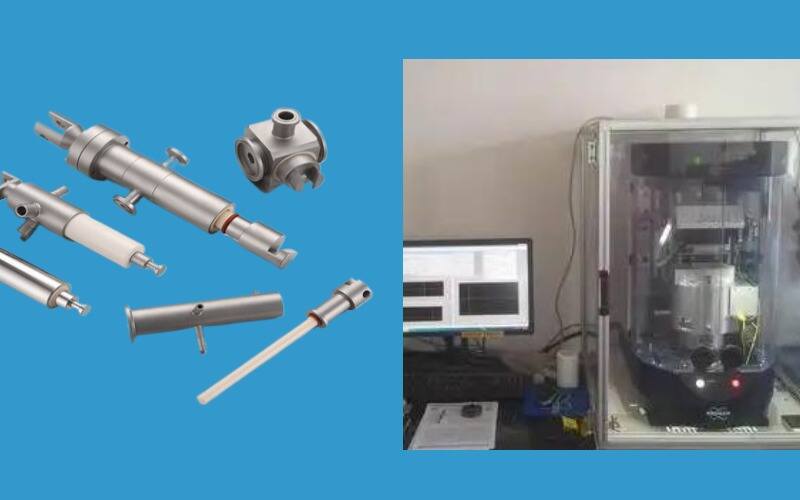

The high wear resistance of alumina ceramics makes it widely used in many fields. In the field of mechanical engineering, alumina ceramics are used as components such as bearings, seals and cutting tools to improve the wear resistance and life of equipment. In the chemical industry, alumina ceramics are often used in wear-resistant parts such as valves, pipes and storage tanks, which can effectively resist corrosion and wear. In addition, alumina ceramics are widely used in electronics, medical devices and automotive, providing wear resistance and high temperature resistance. With the continuous progress of science and technology, the high wear resistance of alumina ceramics will provide new application opportunities for more fields.