What are the surface treatment methods of alumina ceramic plate?

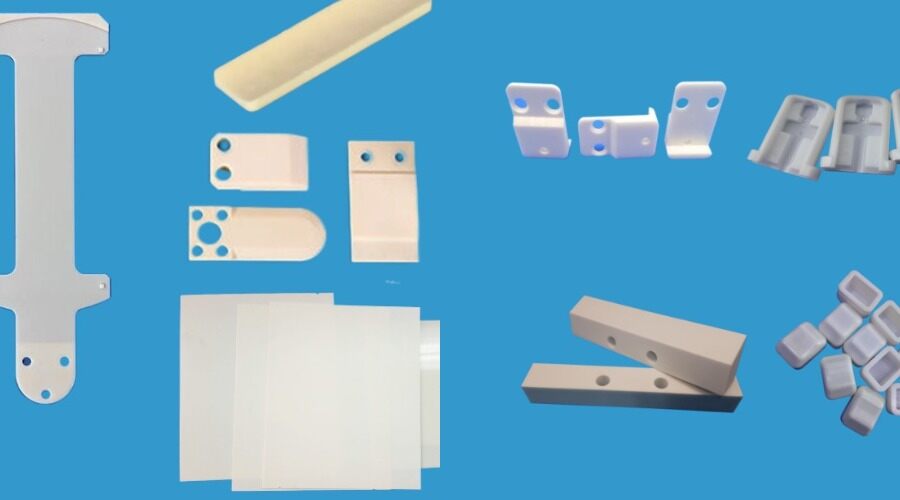

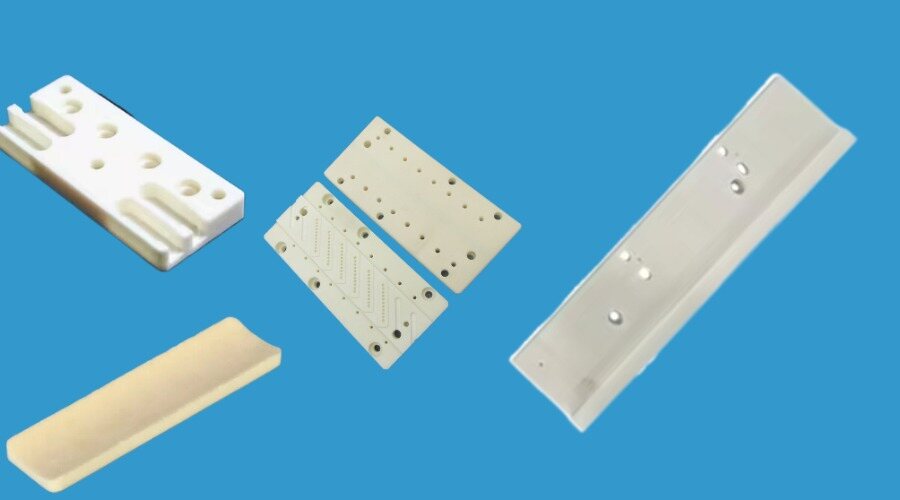

Alumina ceramic plate is a kind of ceramic material with excellent properties, which is widely used in electronic, chemical, medical and other fields. In order to improve the surface properties of alumina ceramic plates, various surface treatment methods are often used. The following will introduce several common alumina ceramic plate surface treatment methods.

Mechanical processing

Mechanical processing refers to the processing of the surface of alumina ceramic plate through mechanical equipment, common methods include grinding, polishing and so on. These methods can remove the defects, small holes and rough edges on the surface of the alumina ceramic plate, and improve the surface processing quality and finish.

Grinding is a method to process the surface of alumina ceramic plate to a certain roughness. Commonly used grinding tools are grinding wheels, cutting tools, etc. Grinding can eliminate the roughness and appearance defects on the surface of alumina ceramic plate, making its surface more flat and smooth.

Polishing is the high-speed rotation of the surface of the alumina ceramic plate through the processing tool, the use of abrasive and polishing fluid to remove the fine dents and scratches on the surface, and get a smoother surface. Polishing can improve the finish and appearance of alumina ceramic plate, so that it has a better texture.

Chemical treatment

Chemical treatment is through a series of chemical reactions to change the nature and structure of alumina ceramic plate surface. Common chemical treatment methods include pickling, solution treatment, electrochemical treatment and so on.

Pickling is to soak the alumina ceramic plate in an acidic solution, and remove the oxide, impurities and oxide layer on the surface through acid erosion. Pickling can improve the cleanliness and purity of the surface of alumina ceramic plate and reduce the influence of surface defects and oxide layer on the performance.

Solution treatment is to soak alumina ceramic plate in a specific solution and change the properties and chemical composition of its surface by reaction. Solution treatment can form a new layer of chemical substances on the surface of alumina ceramic plate, improve its wear resistance, corrosion resistance and chemical stability.

Electrochemical treatment is by adding a certain voltage and current on the surface of alumina ceramic plate, so that it can undergo electrolytic reaction and change the properties and morphology of its surface. Common electrochemical treatment methods include anodic oxidation and anodic grinding. Electrochemical treatment can form an oxide layer with specific functions on the surface of the alumina ceramic plate, such as enhancing the wear resistance, corrosion resistance and electrical conductivity of the ceramic.

Coating treatment

The coating treatment is to coat a specific substance on the surface of the alumina ceramic plate to form a layer of firmly attached protective layer. Common coating treatment methods include chemical vapor deposition, physical vapor deposition, gel coating and so on.

Chemical vapor deposition is the decomposition of the material to be coated into a gas, which causes a chemical reaction on the surface of the alumina ceramic plate to generate a firmly attached coating. This method can make the surface of the alumina ceramic plate have specific functions, such as oxidation resistance, high temperature resistance, enhance adhesion and so on.

Physical vapor deposition is a thin film produced by depositing a layer of physical principles on the surface of alumina ceramic plates, such as evaporation, sputtering, etc. Physical vapor deposition can change the chemical composition and crystal structure of the surface of alumina ceramic plate, and improve the surface hardness, wear resistance and corrosion resistance.

The gel coating method is to coat the specific sol on the surface of the alumina ceramic plate, and form a solid gel layer after heat treatment. The gel coating can improve the wear resistance, corrosion resistance and electrical conductivity of the surface of alumina ceramic plate, and prolong its service life.

The above are several common alumina ceramic plate surface treatment methods, each method has different advantages and disadvantages and scope of application. In practical applications, suitable surface treatment methods can be selected according to specific needs to improve the performance and service life of alumina ceramic plates.