Analysis of the molecular structure of aluminum nitride

Aluminum nitride is a covalent molecule, which consists of nitrogen and aluminum atoms closely bonded by covalent bonds, and has a unique crystal structure and excellent physical and chemical properties.

Aluminum nitride, which sounds like a high-tech material, actually plays an important role in our daily lives and in many industrial fields. So, what molecular structure does aluminum nitride belong to? Let's unravel its mystery.

I. Molecular composition of aluminum nitride

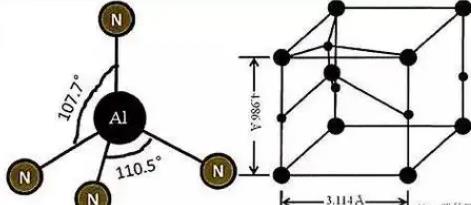

Aluminum nitride, with the chemical formula AlN, is a compound composed of nitrogen atoms (N) and aluminum atoms (Al) in a certain proportion. These two atoms are not simply stacked together, but are closely linked by strong covalent bonds, forming stable aluminum nitride molecules. The existence of this covalent bond makes aluminum nitride have unique physical and chemical properties, such as high hardness, high thermal conductivity and good insulation.

Ii. Crystal structure of aluminum nitride

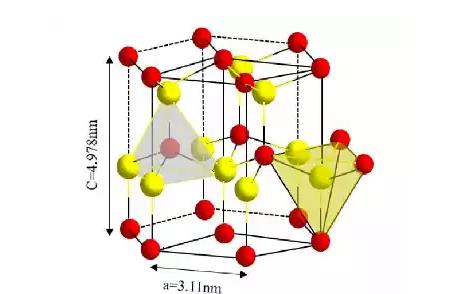

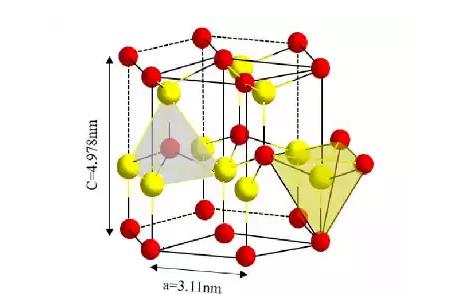

The crystal structure of aluminum nitride is an important reflection of its molecular properties. It usually has a hexagonal wurtzite type structure, in which aluminum and nitrogen atoms are arranged alternately, forming a tight packing pattern similar to a honeycomb. This structure not only enhances the hardness and stability of aluminum nitride, but also makes its internal electron arrangement more orderly, thus having excellent electrical and thermal conductivity properties.

Introduction to the basic knowledge of aluminum nitride ceramics

1. Product nature

1) Composition and structure

The molecular formula of aluminum nitride is Si3N4, which belongs to covalent bonded compounds. Aluminum nitride ceramics are polycrystalline materials with hexagonal crystal structure, generally divided into α and β crystal directions, which are composed of [SiN4] 4-tetrahedra, of which β-Si3N4 has higher symmetry, smaller molar volume, and is thermochemically stable in temperature. And α-Si3N4 is easier to generate in the dynamics, high temperature (1400℃ ~ 1800℃), α phase transformation, β type, this phase transition is irreversible, so α phase is conducive to sintering.

2) Appearance

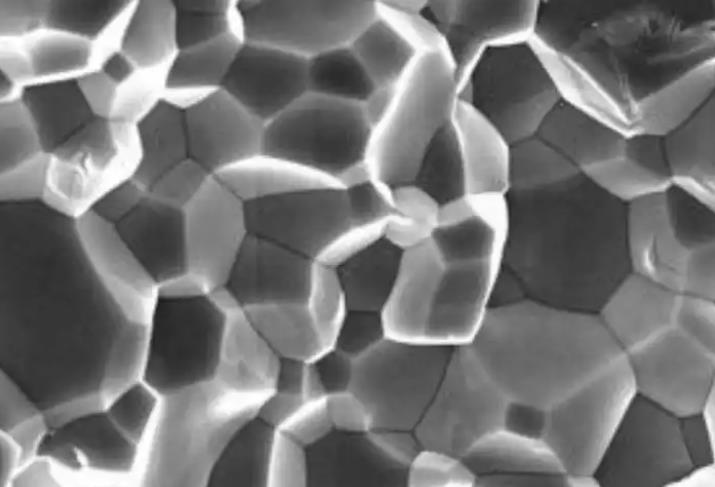

Different crystal phase aluminum nitride appearance is different, α-Si3N4 is white or grayish white, wool-like or acicular, β-Si3N4 is darker, dense granular polyhedron or short prism, aluminum nitride whisker is transparent or translucent, aluminum nitride ceramic appearance is gray, blue gray to gray black, due to density, phase ratio varies. There are also other colors due to additives. Aluminum nitride ceramic surface after polishing, metallic luster.

3) Density and specific gravity

The theoretical density of aluminum nitride is 3100±10kg/m3, and the actual specific gravity of α-Si3N4 is 3184 kg/m3, and the true specific gravity of β-Si3N4 is 3187 kg/m3. The bulk density of aluminum nitride ceramics varies greatly due to the process, generally more than 80% of the theoretical density, between about 2200 ~ 3200 kg/m3, the porosity is the main reason for the different density, the porosity of aluminum nitride reaction sintering is generally about 20%, the density is 2200 ~ 2600 kg/m3. The hot pressed aluminum nitride porosity is below 5%, the density is 3000 ~ 3200 kg/m3, compared with other materials with similar uses, not only the density is lower than all superalloys, but also the density is lower in high temperature structural ceramics.

4) Electrical insulation

Aluminum nitride ceramics can be used as high-temperature insulating materials, and its performance indicators mainly depend on the synthesis method and purity. The free silicon not nitriding in the material, and the alkali metals, alkaline earth metals, iron, titanium, nickel and other factors brought into the preparation can worsen the electrical properties of aluminum nitride ceramics. General silicon nitride ceramics at room temperature, in the dry medium in the specific resistance of 1015 ~ 1016 ohms, the dielectric constant is 9.4 ~ 9.5, at high temperatures, aluminum nitride ceramics still maintain a high specific resistance value, with the improvement of process conditions, silicon nitride can enter the ranks of common dielectric.

5) Thermal properties

Sintered silicon nitride, its thermal expansion coefficient is low, 2.53 × 10-6 /℃, thermal conductivity is 18.42 W/ m ·K, so it has excellent thermal shock resistance, second only to quartz and glass-ceramics, there are experimental reports that the density of 2500 kg/m3 reaction sintered silicon nitride sample by 1200 Cooling to 20℃ thermal cycle thousands of times, still does not break, silicon nitride ceramics have good thermal stability, can be used at high temperature for a long time. It can be used up to 1400 ° C in an oxidizing atmosphere and up to 1850 ° C in a neutral or reducing atmosphere.

6) Mechanical properties

Aluminum nitride has high mechanical strength, the general bending strength of hot pressed products 500 ~ 700MPa, up to 1000 ~ 1200MPa; The flexural strength after reaction sintering is 200MPa, and the high can be 300 ~ 400MPa. Although the room temperature strength of the reaction sintered product is not high, its strength does not decrease at a high temperature of 1200 ~ 1350℃. The creep of aluminum nitride decreases at high temperature. For example, the load of reaction-sintered silicon nitride is 24MPa at 1200℃, and its deformation is 0.5% after 1000h.

7) Friction coefficient and self-lubricity

The friction coefficient of aluminum nitride ceramics is small, under the condition of high temperature and high speed, the friction coefficient is also small, so it can ensure the normal operation of the mechanism, which is one of its outstanding advantages, aluminum nitride ceramics began to grind when the sliding friction coefficient reached 1.0 to 1.5, after precision runin, the friction coefficient is greatly reduced, maintain below 0.5, Therefore, aluminum nitride ceramics are considered to be self-lubricating materials. The main reason for this self-lubricity, which is different from graphite, boron nitride, talc, etc., is the scale layer structure of the material organization. It is under the action of pressure, the friction surface is micro-decomposed to form a thin gas film, so that the sliding resistance between the friction surface is reduced, and the friction surface is increased. In this way, the more friction, the smaller the resistance, the wear amount is particularly small, and most materials in continuous friction, due to surface wear or temperature rise softening, the friction coefficient is often gradually increased.

8) Machinability

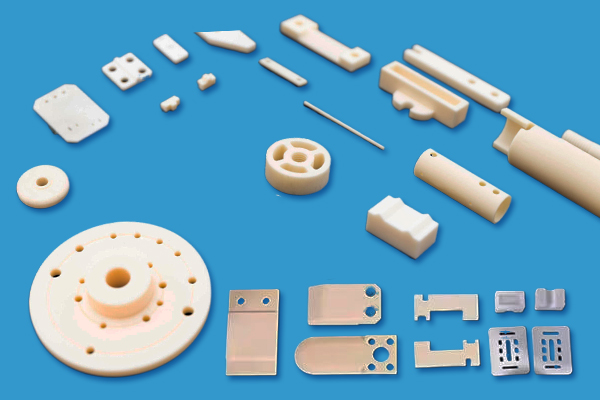

Aluminum nitride ceramics can be machined to achieve the required shape and precision, surface finish.

9) Chemical stability

Aluminum nitride has excellent chemical properties, and can resist all inorganic acids except hydrofluoric acid and sodium hydroxide solution less than 25% corrosion. It is resistant to oxidation at temperatures up to 1400 ° C, and can be used up to 1870 ° C in a reducing atmosphere, and is non-wetting to metals (especially liquid AL), especially non-metals. From the above physical and chemical properties of aluminum nitride ceramics, it can be seen that the excellent performance of aluminum nitride ceramics has special use value for the working environment of high temperature, high speed and strong corrosive media often encountered by modern technology. Its outstanding advantages are:

The advantages

(1) High mechanical strength, hardness close to corundum. The bending strength of hot-pressed silicon nitride at room temperature can be as high as 780-980mpa, and some even higher, compared with alloy steel, and the strength can be maintained to 1200 ℃ without falling.

(2) Mechanical self-lubrication, small surface friction coefficient, wear resistance, large elastic modulus, high temperature resistance.

(3) The thermal expansion coefficient is small, the thermal conductivity is large, and the thermal shock resistance is good.

(4) Low density and small specific gravity.

(5) Corrosion resistance and oxidation resistance.

(6) Good electrical insulation.

Application

(1) In the metallurgical industry, the production of crucible, Muffle furnace furnace, combustion nozzle, heating element fixture, casting mold, aluminum conduit, thermocouple protection sleeve, aluminum electrolytic cell lining and other thermal equipment components.

(2) In the machinery manufacturing industry to produce high-speed turning tools, bearings, metal parts heat treatment support, rotor engine blades, gas turbine guide blades and turbine blades.

(3) Used in the chemical industry as ball valves, pump bodies, sealing rings, filters, heat exchanger parts and immobilized catalyst carriers, combustion boats, evaporating dishes.

(4) In the semiconductor, aviation, atomic energy and other industries for the manufacture of switching circuit substrates, film capacitors, high temperature or temperature change of electrical insulators, radar wire cover, missile nozzle, atomic reactor support and isolation parts, carrier of nuclear fissile material.

(5) Artificial joints can be done in the pharmaceutical industry.