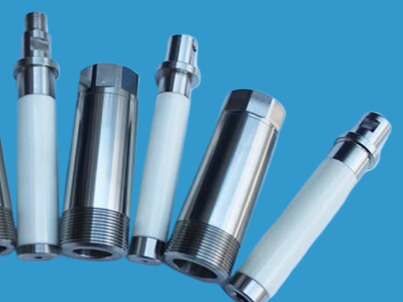

The difference between ceramic plunger and metal plungers

Ceramic plungers and metal plungers are common sealing materials, with the continuous development of science and technology, they have been widely used in different application fields. In the selection and identification of the plunger, many consumers will wonder what is the difference between them, the following author will be analyzed from the characteristics and differences of two perspectives.

Peculiarity

1. Ceramic plunger

Ceramic plunger is made of high purity alumina at high temperature, and has the advantages of high hardness, high temperature resistance, acid and alkali etching resistance. Therefore, it is widely used in the need of high strength, wear resistance, corrosion resistance, high temperature resistance, good sealing fields, such as petroleum, chemical, gas, water treatment and other industries of needle valve seal structure, constant pressure pump, gas-liquid booster pump, pneumatic hydraulic components.

2. Metal plunger

Metal plunger is made of stainless steel, copper, aluminum and other materials, with high strength, wear resistance, corrosion resistance, good machinability and other advantages. Therefore, it is widely used in mechanical equipment, construction machinery, automotive, aerospace, manufacturing and other fields of sealed door structure, shock absorber, brake system and so on.

Distinction

1. Observe the appearance: the appearance of the ceramic plunger is smooth and without obvious defects, the surface of the plunger has strong pressure resistance, wear resistance and corrosion resistance, and the surface of the metal plunger is mostly bright, and some subtle defects can be seen.

2. Test weight: The ceramic plunger has a relatively high density and relatively light weight, while the metal plunger has a relatively large density and heavy weight.

3. Test hardness: Ceramic plunger hardness is high, wear resistant, can resist strong impact, while metal plunger hardness is low, wear resistance is poor, can only resist ordinary impact.

4. Observe the degree of wear: a layer of metal oxide will appear on the surface of the metal plunger after wear, while cracks and wear marks will appear on the surface of the ceramic plunger.

The performance of ceramic and metal plungers is very different. Ceramic plunger has good wear resistance, corrosion resistance and excellent fatigue resistance. Ceramic material has high hardness, low friction coefficient, small wear, and is not easy to deformation, so the sealing of ceramic plunger is better. On the contrary, the metal plunger is relatively poor in terms of wear and corrosion resistance, but its high temperature resistance and pressure resistance are better than ceramic materials.

Materials

Ceramic plungers use ceramic materials, while metal plungers are made of metal materials. Ceramic materials are amorphous structure, common alumina, silicon nitride and other materials. Ceramic material has high hardness, high strength, high temperature resistance, corrosion resistance and other excellent properties. The metal materials are stainless steel, copper, aluminum and other main materials, with good machinability, electrical conductivity, thermal conductivity and other characteristics.

Life span

Because ceramic plunger has high hardness, wear resistance, corrosion resistance and other excellent characteristics, its service life is obviously longer than that of metal plunger. The metal plunger is affected by wear, corrosion and other factors, and the life is relatively short.

In summary, there are differences between ceramic plungers and metal plungers in terms of material, performance and life. Therefore, when selecting the plunger, it is necessary to select the plunger suitable for the material according to the conditions and requirements of use in order to achieve the best use effect.

What is a ceramic plunger? The characteristics and application scenarios of ceramic plunger are explained in detail

Definition and characteristics of ceramic plunger

Ceramic plungers are cylindrical parts made of ceramic materials that are commonly used for sealing and regulating in fluid control systems. Compared with ordinary metal plungers, ceramic plungers have the following characteristics:

1. Good wear resistance: the hardness and wear resistance of ceramic materials are better than that of metal materials, so the service life of ceramic plungers is longer.

2. Strong corrosion resistance: Because ceramic is a material with high chemical stability, ceramic plungers have good corrosion resistance.

3. Good sealing performance: Due to the high surface finish of the ceramic material, the ceramic plunger can get a good sealing effect.

4. Good temperature stability: the linear expansion coefficient of ceramic material is small, and it has good temperature stability and thermal shock performance.

The application scenario of ceramic plunger

1. Automotive engine: Ceramic plungers can be used in the injection system of automotive engines to improve fuel injection accuracy and combustion efficiency and reduce exhaust emissions.

2. Hydraulic system: Ceramic plungers can be used for sealing and flow control in hydraulic pumps or hydraulic motors.

3. Medical devices: Ceramic plungers can be used in high-precision infusion and injection systems in medical devices to ensure that the liquid does not leak out.

4. Chemical equipment: Ceramic plungers can be used for high temperature, high pressure and corrosive liquid flow control in chemical equipment.

In short, because the ceramic plunger has the characteristics of wear resistance, corrosion resistance and good sealing performance, the ceramic plunger can be used to replace the traditional metal plunger in some scenarios requiring relatively high control accuracy, such as automotive, medical, chemical and other fields.