Cleaning machine pump head ceramic plunger and metal plunger difference

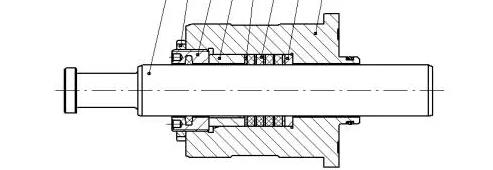

When cleaning the car, the pump head used is an important part of it. The plunger in the pump head is the key component to ensure the normal operation of the cleaning machine. For different materials of the plunger, its performance and application scenarios are also different. In this paper, the ceramic plunger and steel plunger in the pump head of cleaning machine are compared, and the difference between them is analyzed.

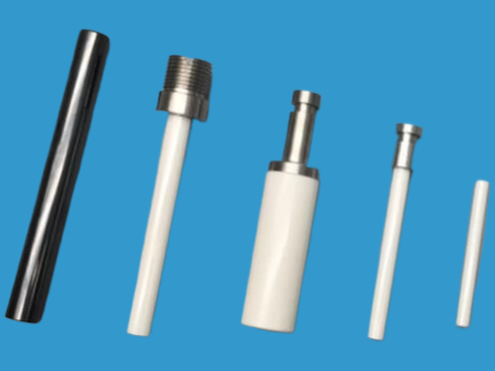

Characteristics and use scenarios of ceramic plunger

Ceramic plunger is a kind of washer plunger material widely used in vehicle maintenance industry. Due to its unique structure and properties, ceramic plungers have the following characteristics:

1. Corrosion resistance: The reaction of ceramic plungers with chemicals and corrosive liquids is weak, and the service life is long.

2. High hardness: ceramic hardness is higher, more wear resistance than the metal plunger, long service life, the possibility of failure and wear is low.

3. Easy thermal conductivity: ceramic plunger has good thermal conductivity, which can help rapid heat dissipation and long service life.

We need to note that the use of ceramic plungers is mainly under high pressure, suitable for spray, cleaning and impact cleaning machine applications. However, if used under low pressure, it is easy to damage the parts.

Characteristics and use scenarios of metal plunger

The metal plunger is a common material in the pump head of the southpointing machine, and its characteristics are as follows:

1. High compressive strength: compared with ceramic material, the pressure bearing capacity of metal plunger is stronger.

2. A wide range of application scenarios: metal plungers are suitable for automobile maintenance, industrial cleaning, high-pressure painting and other industries and applications.

It should be noted that the wear of the metal plunger will allow the remaining harmful substances to remain in the pump, resulting in easy failure of the cleaning machine.

Comparison of ceramic and metal plungers

1. Service life: the service life of the ceramic plunger is longer, but it needs to be used under high pressure; The service life of the metal plunger is short, but the applicability is wide.

2. Compressive strength: The compressive strength of the steel plunger is higher than that of the ceramic plunger.

3. Corrosion resistance: the corrosion resistance of ceramic plungers is stronger than that of steel plungers.

4. Cost performance: The metal plunger is more cost-effective, but it requires frequent maintenance before use, and the ceramic plunger does not need frequent maintenance.

By comparing the characteristics, application scenarios and advantages and disadvantages of the ceramic plunger and metal plunger in the pump head of the cleaning machine, this paper makes suggestions for vehicle maintenance practitioners in purchasing and using the cleaning machine, and improves the efficiency of the use of the cleaning machine and the production safety in the process of cleaning and maintenance.