difference between zirconia and ceramic

What is the difference between zirconia ceramics and pure ceramics?

In the world of ceramics, zirconia ceramics, with its outstanding performance and wide range of application fields, is gradually standing out among various ceramic materials and becoming the preferred choice for industrial manufacturing and artistic creation. So, what are the differences between zirconia ceramics and pure ceramics? Let's uncover the mystery of this exciting showdown between materials and properties together.

Material Properties Comparison

Zirconia Ceramic

Zirconia ceramic is renowned for its high hardness, high strength, wear resistance, corrosion resistance, and high-temperature stability. Its hardness exceeds that of ordinary steel, and its strength is 2-3 times that of ordinary ceramics. This unique material property enables zirconia ceramic to shine in high-end mechanical equipment, medical devices, aerospace, and electronic components. Whether it is the ceramic cylinder liner for oil drilling or the packaging of precision electronic components, zirconia ceramic can meet various demanding application requirements with its outstanding performance.

Pure Ceramic

Pure ceramic, as a representative of traditional ceramics, is renowned for its excellent insulation properties, high temperature resistance, and chemical stability. However, compared to zirconia ceramic, pure ceramic is slightly inferior in terms of hardness and strength. Its raw materials are relatively simple and the process complexity is lower, making it more suitable for applications in daily utensils, decorations, and handicrafts.

Comparison of Process and Appearance

Zirconia ceramic

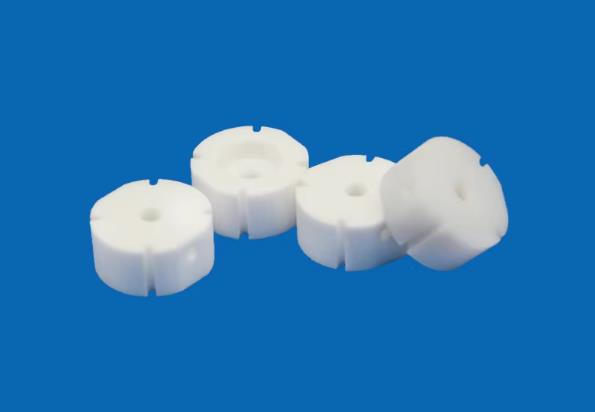

The manufacturing process of zirconia ceramic is relatively complex, involving multiple procedures such as ultra-low-speed fine processing and high-temperature sintering to complete. This meticulous process gives zirconia ceramic a gray-white, fine texture and high gloss. Whether used for the case and chain of high-end watches or as denture material for oral dentistry, zirconia ceramic can showcase its unique charm and quality.

Pure Ceramic

The manufacturing process of pure ceramics is relatively simple. Generally, steps such as molding, drying, and sintering are sufficient to complete the process. Due to its lower production cost, the quality is relatively uneven. However, this also provides more possibilities for artistic creation. Whether it is colorful ceramic artworks or practical and durable ceramic tableware, pure ceramics can win the affection of consumers with its unique charm and texture.

Application Domain Comparison

Zirconia Ceramics

The wide range of applications of zirconia ceramics is the best proof of its outstanding performance. From wear-resistant structural components in oil drilling, to packaging materials for precision electronic components; from dentures and surgical instruments for medical devices, to thermal shielding materials for aerospace and aviation; zirconia ceramics can meet various complex and demanding application requirements with its excellent performance.

Pure Ceramic

Although the application fields of pure ceramics are relatively limited, their significance in daily life cannot be ignored. Whether it is kitchenware and appliances, or cleaning supplies and decorations in the bathroom; pure ceramics can provide consumers with safe, practical and aesthetic choices through its excellent insulation, high-temperature resistance and chemical stability.