The function and application field of ceramic tube

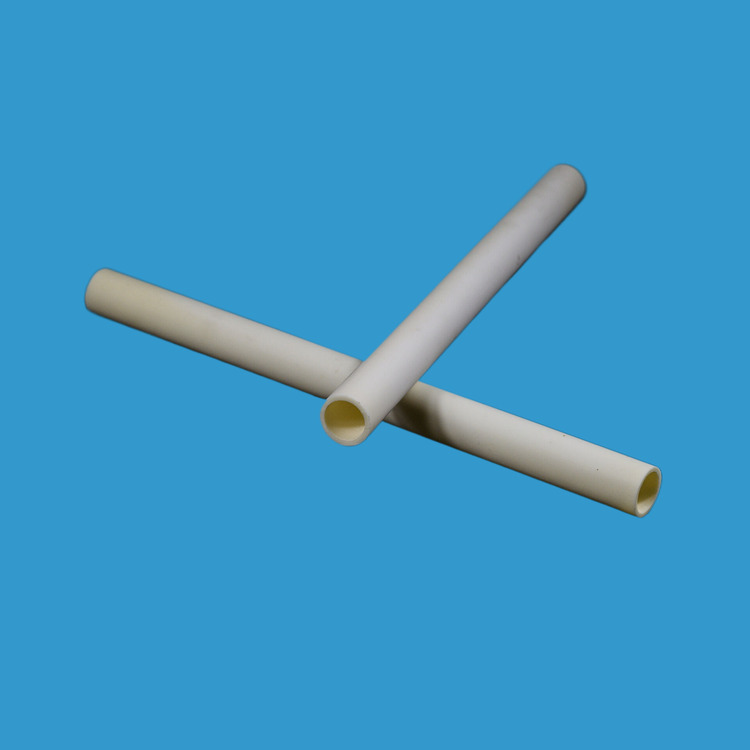

Ceramic tube is a kind of tube with excellent physical and chemical properties, mainly made of alumina, zirconia and other ceramic materials. ceramic tube has excellent wear resistance, corrosion resistance, high temperature, high pressure, insulation, heat insulation, radiation resistance, non-toxic and other characteristics, so it is widely used in machinery, electronics, chemical and medical fields.

The function of ceramic tube

Ceramic tubes mainly have the following functions:

1. Wear parts: Ceramic tube can be used as an important wear part, with wear resistance, corrosion resistance, low viscosity, low resistance and other advantages, can extend the service life of machine parts.

2. Electrical insulator: Because the ceramic tube has high physical and chemical properties and electrical insulation properties, it can be used as an electrical insulator and is widely used in power, electronics and other fields.

3. Thermal isolator: The thermal conductivity of ceramic tube is low, so it can be used to make high temperature isolators, applied to high temperature occasions such as boilers and furnaces.

4. Medical treatment: Ceramic tube has the characteristics of antibacterial, non-toxic and harmless, so it can be used in artificial organs, dentures, medical porcelain and other high-end medical fields.

5. Other fields: Ceramic tubes can also be used in electronics, chemical and other fields, such as the production, storage and transportation of corrosive substances, the use of alumina ceramic tubes can avoid the corrosion reaction between the substance and the metal tube.

Application fields of ceramic tube

The application areas of ceramic tubes are very wide, and common areas include:

1. Machinery: Pumps, valves and tubelines for conveying various fluid media.

2. Chemical industry: used to transfer corrosive media, manufacture chemical reactor, storage tank, etc.

3. Electronics: Used to make capacitors, inductors, photoelectric devices, etc.

4. Medical treatment: Used for artificial organs, dentures, medical equipment.

5. Environmental protection: used for industrial waste gas purification, acid fog emission, hazardous waste disposal, etc.

Advantages and limitations of ceramic tube

Ceramic tubes have excellent physical and chemical properties and many applications, but they also have some limitations.

Advantages: ① Widely used in various fields; ② Excellent performance, wear resistance, corrosion resistance, high temperature, high pressure, insulation, heat insulation, radiation resistance, non-toxic, etc.; ③ Can be designed and customized according to specific requirements.

Limitations: ① high cost; ② Easy to fracture, high protective measures; (3) Ceramic tube processing requirements are high, and manufacturing is difficult.

In summary, ceramic tubes have an important function and a wide range of application fields, although there are some limitations, but with the continuous improvement of technology and process improvement, its application prospects are still broad.