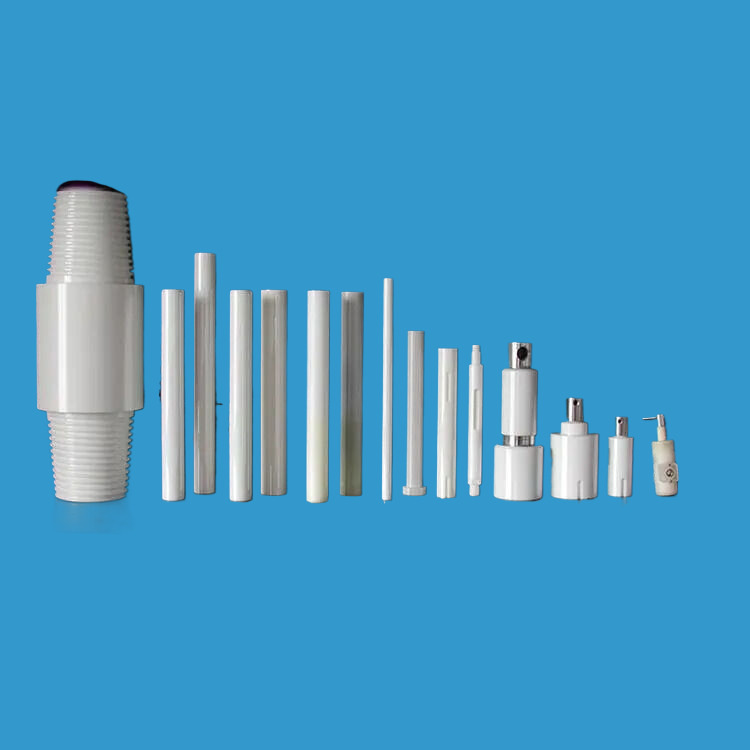

How to drill out a ceramic shaft

Ceramic shaft drilling needs to choose carbide drill bit or diamond drill bit, of which diamond drill bit is better. When operating, pay attention to control the speed and feed speed to avoid excessive rupture.

Ceramic is a kind of material with high hardness and good wear resistance, so it is widely used in many fields. However, due to its high hardness, it is easy to break or damage when drilling, so it is particularly important to choose the right drill bit and the correct operation method.

Several processing methods of ceramic shaft punching

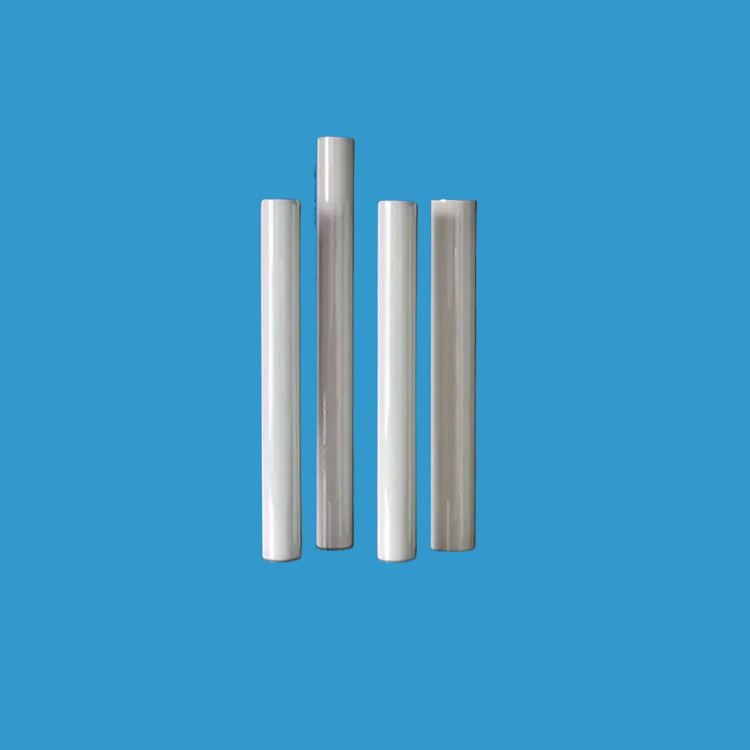

There are many ways to drill ceramic shafts, among which common ones include mechanical drilling, electric discharge machining, and laser drilling. Here's a quick comparison:

Laser drilling: Laser drilling is a commonly used ceramic shaft drilling method. It uses a high energy laser beam to process the ceramic shaft, and through the thermal effect, the material instantly evaporates or melts to form holes. Laser drilling has the characteristics of non-contact, high precision and high efficiency, and can realize the aperture and hole distance control at the micron level, which is suitable for precision drilling needs.

Mechanical drilling: Mechanical drilling is one of the traditional ceramic shaft drilling methods. It uses a rotating tool (such as a drill) to process the ceramic shaft. Mechanical drilling speed is relatively slow, need to gradually cut ceramic materials, and easily lead to tool wear. Mechanical drilling is suitable for general drilling requirements that do not require high aperture and hole spacing.

Electrical Discharge Machining (EDM) is a method of perforating a ceramic shaft material by means of electrical discharge machining. It uses an electrical pulse to generate an electrical spark discharge between the workpiece surface and the electrode, causing local corrosion and dissolution of the material to form holes. Edm is suitable for ceramic materials with high hardness, but the control of aperture and hole distance is relatively poor.

First. Prepare tools

Before drilling ceramic, you need to prepare the following tools: drill, electric drill, alcohol, pen or charcoal strip. First, the ceramic shaft is washed and dried, and then wiped clean with alcohol where the ceramic shaft is to be drilled. A pen or charcoal strip can be used to mark the ceramic shaft so that it is easy to find the exact location when drilling.

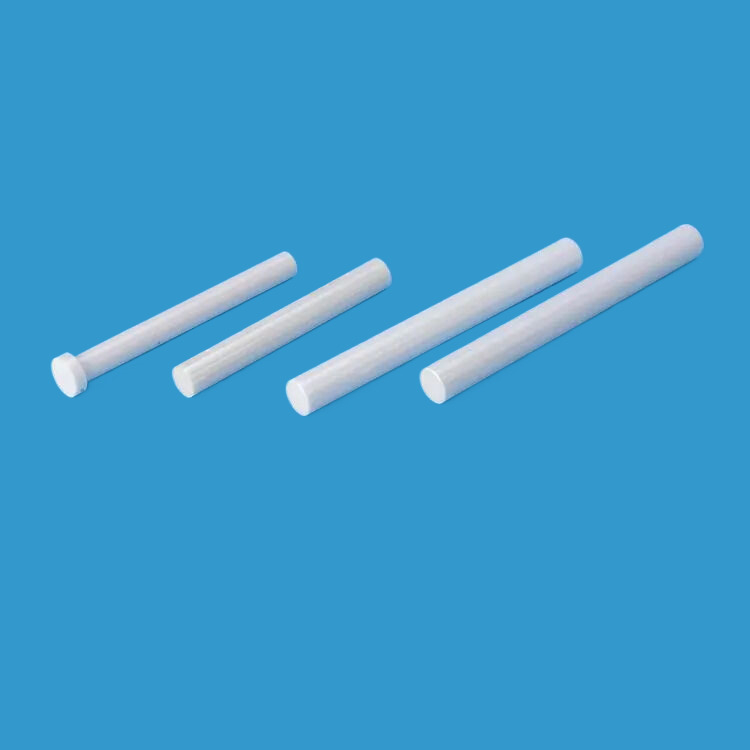

Second, select the drill

Drilling ceramic shafts requires the use of special drill bits, usually tungsten plated bits. The drill bit is harder and wear-resistant than ordinary steel drills and can drill holes quickly and accurately. It should be noted that the diameter of the bit should be suitable for the size of the ceramic shaft hole to be drilled.

Carbide drill bit: Carbide drill bit is a commonly used ceramic shaft drilling tool, suitable for ceramic shafts of general thickness. Its advantage is that the price is relatively low, but it should be noted that due to the high hardness of the ceramic, the speed and feed speed need to be properly reduced when drilling to avoid overheating or fragmentation of the drill bit.

2. Diamond drill bit: Diamond drill bit is a more advanced ceramic shaft drilling tool, with higher hardness and wear resistance, suitable for thicker or harder ceramic materials. Although the price is relatively high, the drilling effect is better, which can improve work efficiency and drilling quality.

Three, adjust the speed and Angle

When using an electric drill to drill a ceramic shaft, attention should be paid to controlling the speed and Angle. Too fast or too slow will affect the efficiency and service life of the drill. In general, the speed should not be too fast to avoid overheating damage to the drill. The Angle should also be appropriate, generally keep it perpendicular to the surface of the ceramic shaft.

Four. Start drilling

After installing the tungsten-plated bit, start drilling. Generally start at a slow speed, and then accelerate until the hole is deeper. It should be noted that the operation should not use too much force, and should maintain a certain stability and durability.

Five. Handle the corners

After drilling, you can use a small file tool to treat the corner of the hole to make it more smooth. This ensures the integrity and aesthetics of the ceramic shaft holes.

In short, drilling ceramic shafts requires the selection of appropriate tools and skills to ensure the quality and effect of ceramic shaft holes.