Analysis of laser rotary cutting drilling technique for ceramic plate substrate

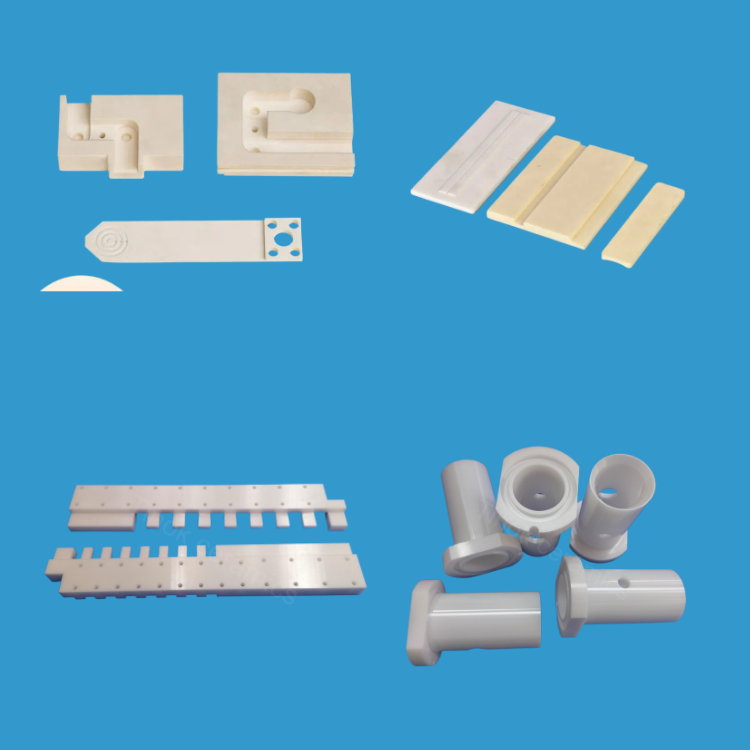

Ceramic plate substrate is a kind of basic material widely used in semiconductor packaging. In the semiconductor packaging industry, the processing of ceramic plate substrates usually requires a drilling process to meet the layout needs of electronic components. The traditional drilling method is mechanical drilling, but this method has some disadvantages, such as high cost, insufficient precision, long occupation time and so on. In order to solve these problems, laser rotary cutting drilling technology of ceramic plate substrate came into being.

The process flow

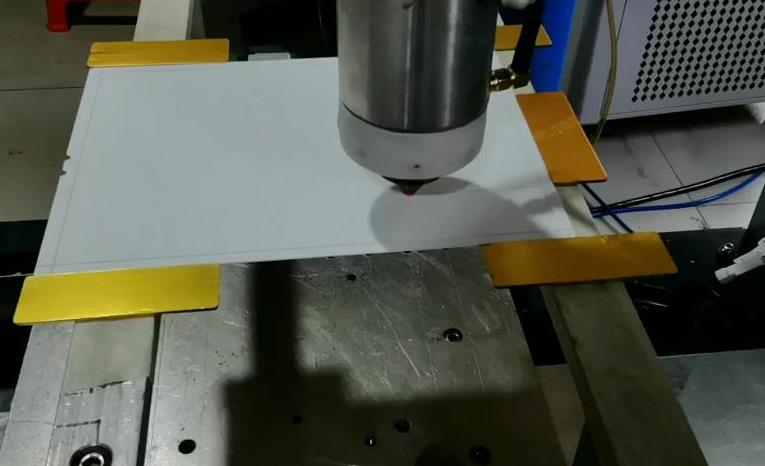

Laser rotary cutting drilling of ceramic plate substrate is a laser processing technology. It uses a rotating ceramic plate substrate, coupled with a high energy laser cutting tool, the rotary cutter can cut the plate substrate quickly and accurately, and can cut tiny drill holes. The specific process flow is as follows:

1. Design CAD drawings, including information such as the drilling position and drilling aperture of the plate substrate.

2. Prepare and reinforce the ceramic plate substrate. Seal the ceramic plate substrate on the copper plate with adhesive to improve stability and ensure spatial accuracy.

3. Pre-cut so that each drill hole is aligned with a point on the cross-section of the plate substrate.

4. Set the laser rotary drilling device, including laser parameters and rotational speed.

5. Start laser rotary drilling, automatic drilling according to CAD drawings.

6. Check the drilling quality.

Advantages and disadvantages

The laser rotary cutting drilling process for ceramic plate substrate has many advantages. First, it does not damage the plate substrate, ensuring the electrical performance of the component. Second, it is effective in areas where smaller apertures (less than 100 microns) are required. In addition, it has the advantages of high efficiency and high precision. However, this processing method also has shortcomings. For example, laser processing generates high heat, which requires pretreatment and cooling. In addition, the quality of laser drilling is affected by many factors, such as bit wear, plate substrate surface state and laser power. Therefore, the precision and quality of laser drilling need attention and adjustment.

Improve quality and efficiency

In order to improve the quality and efficiency of laser rotary cutting drilling on ceramic plate substrate, it is necessary to start from the following aspects:

1. Select appropriate ceramic materials and appropriate processing parameters to ensure drilling accuracy and quality.

2. Take pre-treatment and cooling measures to reduce laser damage to the plate substrate.

3. Implement reasonable processing flow, such as drilling automation, pre-cutting and other steps in CAD drawings.

4. Carefully maintain the equipment, regularly replace the laser cutter and rotating block drill bits, and keep the laser power stable.

The above measures can effectively improve the quality and efficiency of laser rotary cutting drilling on ceramic plate substrate.

As a new technology in semiconductor packaging industry, laser rotary cutting drilling of ceramic plate substrate has played an important role in practical application. It can quickly and accurately complete the drilling process, and is suitable for different pore sizes and different shapes of ceramic plate substrates. At the same time, we need to know the limitations of the technology and understand ways to improve processing efficiency and reduce costs.