What are the finishing machining and technologies of ceramic rods

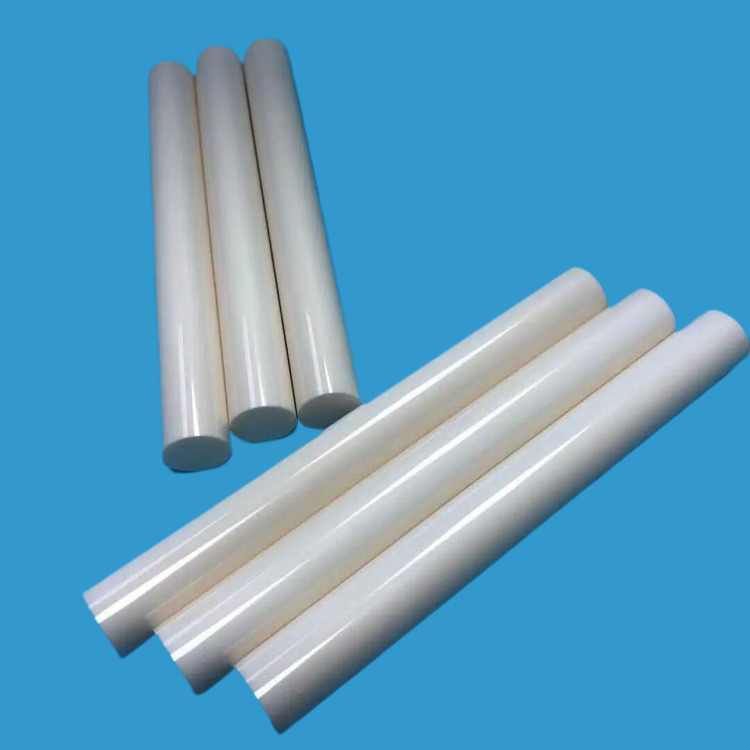

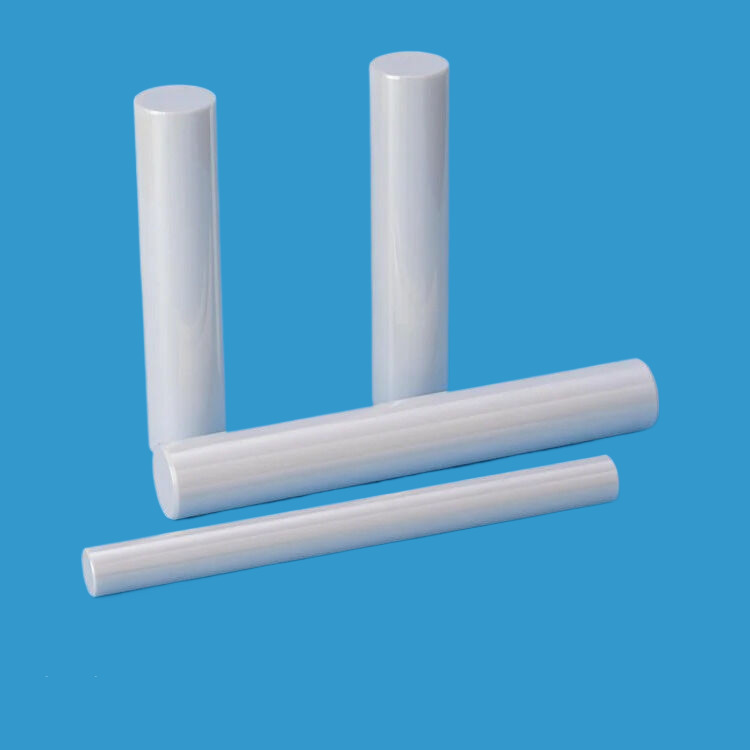

Ceramic rods are generally made of zirconia or alumina as raw materials and are formed by isostatic pressing, hot die casting, dry pressing and other machining. Ceramic rods are widely used in aerospace, medical equipment, military machinery and other high-end fields. Our processing experience is rich, can be turned, milling, planing, grinding, drilling, cutting, tapping and other processing and achieve high accuracy; Dimensional accuracy: up to 0.001; Finish: up to atomized mirror.

The following is a detailed introduction to the ceramic rod processing technology:

First, ceramic rod polishing

After the ceramic rod is sintered out, the surface is very rough, and it needs to be polished by centerless grinding and grinding equipment. Our polished ceramic rod can achieve the effect of atomizing mirror.

Second, ceramic bar chamfer

Ceramic bar chamfer is 45 degrees, 60 degrees, 90 degrees, we have a ready-made grinding wheel, ceramic bar can be poured at different angles.

Three, ceramic rod grooving

Ceramic rods can be slotted on one side or two sides! Slot can be opened according to different customer requirements.

Four, ceramic rod drilling

The ceramic bar can be perforated on the end face and cylindrical surface according to customer requirements.

Five, ceramic rod straightness processing

The straightness of the ceramic rod is related to the length of the ceramic rod, the longer the easier to bend, generally 100mm long ceramic rod we can control the straightness of 0.1mm, 300mm long straightness of 0.3mm.

Six, ceramic rod cylindrical processing

The outer circle of the ceramic rod generally needs to be cylindrical grinding, and the roundness of the ceramic rod can reach 0.002mm.

Ceramic rod has good mechanical properties, with fall resistance, wear resistance, super strength, super hard, high temperature resistance (fire resistance), super corrosion resistance, never rust, oxidation resistance, insulation, lubrication and other excellent properties. The material has excellent insulation performance, no porosity, high temperature resistance, low temperature resistance, heat shock resistance, and no ventilation characteristics. The hardness of zirconia ceramics is high, the brittleness of the material is large, and it is easy to collapse and fracture during processing. Usually, ceramic parts are processed using special ceramic engraving machining, which can effectively reduce costs and achieve high precision machining.