What are the materials of the plunger pump

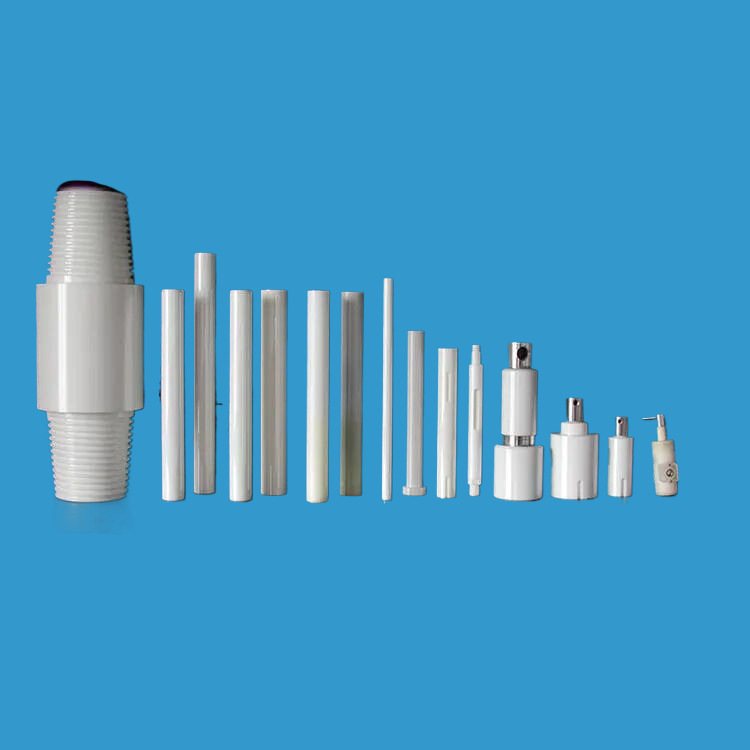

Plunger pump plunger materials mainly include hardened stainless steel and ceramic. Ceramic plungers are known for their high wear resistance, using modern engineering ceramic materials with high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties.

Cast steel plunger

Cast steel plunger is a commonly used plunger material, which is made by casting process and has the characteristics of high strength, good rigidity and light weight. The hardness of the cast steel plunger can be adjusted by quenching, tempering and other processes, and is usually used in high pressure pumps or high temperature and high pressure pumps in the industrial field.

Stainless steel plunger

Stainless steel plunger is made of stainless steel material, mainly used for corrosion, oxidation and other special conditions of the system. Stainless steel plungers can be surface treated according to specific needs, such as chrome plating, nickel plating, etc., to improve its corrosion resistance and service life.

Ceramic plunger

Ceramic plunger refers to a plunger assembly made of ceramic materials. The ceramic plunger material has high hardness, strong wear resistance, high surface smoothness, and will not cause problems such as loosening or expansion due to too high working temperature. Due to the stable nature of the ceramic plunger, it is mostly used in precision industries such as high-pressure car washing.

Cemented carbide plunger

Cemented carbide plunger is a new type of plunger material, which is made by mixing and pressing cobalt powder, tungsten carbide powder and other materials through a specific production process. Cemented carbide plungers have high hardness and strong wear resistance, so they can meet the needs of high pressure and high power working environments, and are often used in the oil well pump or high pressure injection pump in the oil industry.