How to evaluate the quality and effect of precision ceramic machining?

The quality and effect evaluation of precision ceramic machining is an important link to ensure the stability of product performance and meet customer needs. The evaluation process usually includes the following considerations: raw material selection, process flow, equipment and tool selection, process control, and performance verification of the final product. The evaluation methods and basis for these aspects are described in detail below.

Selection of raw materials

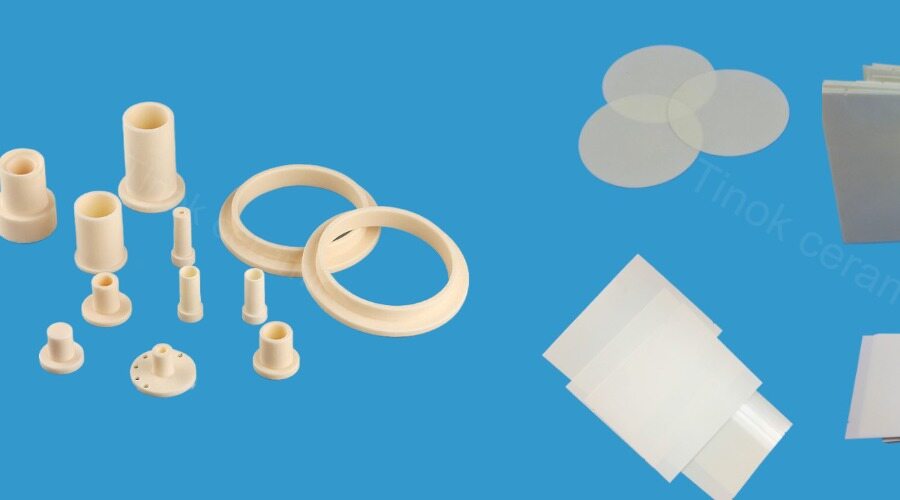

The quality and effect of precision ceramics largely depend on the choice of raw materials. Commonly used precision ceramic raw materials include alumina, silicon nitride, silicon carbide and so on. There are several methods to evaluate the quality of raw materials:

Physical properties test

Evaluate the quality of raw materials by testing their physical properties, such as density, hardness, compressive strength, etc.

Chemical analysis

Use chemical analysis methods to analyze the composition and impurity content of raw materials to ensure compliance with requirements.

Microstructure observation

Use a microscope to observe the degree of crystallization, grain size and impurity distribution of raw materials to evaluate their quality.

Process evaluation

The process flow has great influence on the quality and effect of precision ceramic machining. When evaluating the process flow, the following factors should be considered:

Process feasibility

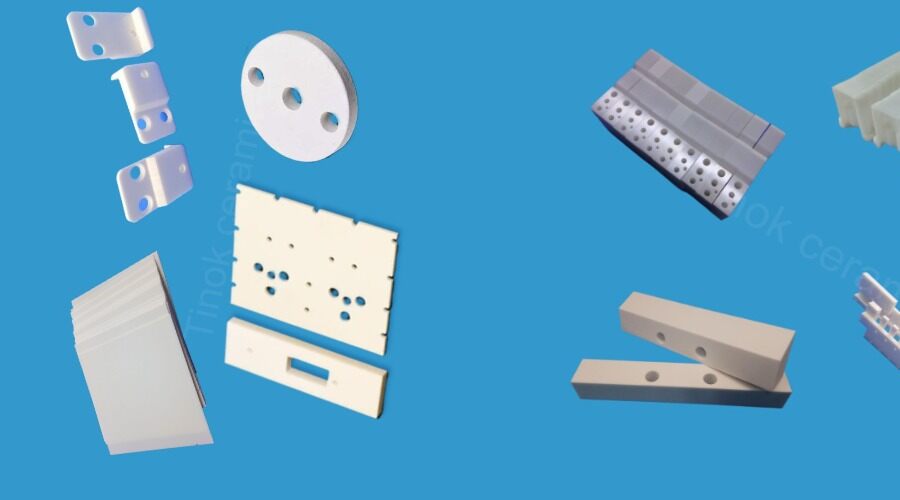

Evaluate whether the process can meet the requirements of the product, including machining accuracy, surface quality, etc.

Process stability

Evaluate the stability and repeatability of the process to ensure a stable product for each production.

Process parameter control

evaluate the control ability of process parameters, including the control range and accuracy of temperature, pressure, speed and other parameters.

Select equipment and tools

The choice of equipment and tools also has a great impact on the quality and effect of precision ceramic processing. When evaluating equipment and tools, consider the following aspects:

Equipment performance: Evaluate the accuracy, stability and adaptability of the equipment to ensure that it can meet the processing requirements of the product.

Tool quality

Evaluate the material, manufacturing process, etc. of the tool to ensure its quality and service life.

Process control

Process control is an important link to ensure quality and effect in precision ceramic machining. There are several main ways to evaluate process control:

Detection method

Select the appropriate detection method, such as optical microscope, scanning electron microscope, etc., to detect and monitor the quality of different links and processes.

Data analysis

analysis and statistics of the collected processing data to evaluate the control ability and stability of the processing process.

Process optimization

Improve the processing quality and efficiency of products through the optimization of the processing process.

Product performance verification

The performance verification of the final product is the most important step to evaluate the quality and effect of precision ceramic machining. The main evaluation methods are as follows:

Product testing

Perform necessary tests on the final product, such as physical performance testing, chemical analysis, screen printing, etc., to verify whether the performance of the product meets the requirements.

Product practical application test

The product is applied to actual scenarios to evaluate its use effect and lasting performance in actual environments.

In short, the quality and effect evaluation of precision ceramic processing needs to consider raw material selection, process flow, equipment and tool selection, process control and performance verification of the final product. Through reasonable evaluation methods and basis, we can ensure the stability of products and customer satisfaction.