The reason and the solution of alumina ceramics porosity

What is the phenomenon that alumina ceramics have many pores?

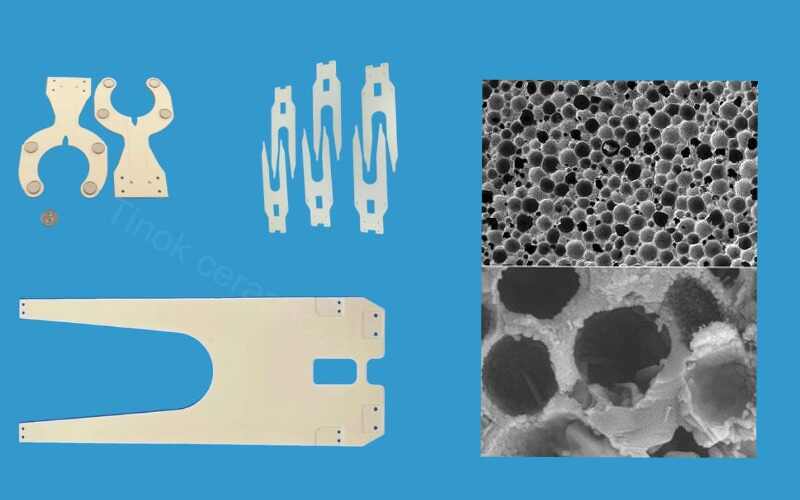

Alumina ceramic is a kind of ceramic material with high strength, high hardness, high temperature stability and chemical stability. It is widely used, including electronics, machinery, petrochemical, medical devices and other industries. However, in the processing of alumina ceramics, there will be a phenomenon of more pores, that is, a larger number of pores in the material.

What is the reason for the porosity of alumina ceramics?

The main reasons for the porosity of alumina ceramics are as follows:

1. Gases and impurities in the material: During the preparation of ceramic materials, if there are gases or impurities in the material, pores will be formed during the sintering process.

2. Non-uniformity of the preparation process: sintering is a necessary process for the preparation of alumina ceramics, but the non-uniformity of the sintering temperature and sintering cycle will lead to the phenomenon of porosity.

3. The sintering temperature is not high enough: the sintering temperature is not high enough is also one of the important factors leading to the porosity of alumina ceramics.

How to solve the problem of alumina ceramics porosity?

The following are some ways to solve the problem of porosity in alumina ceramics:

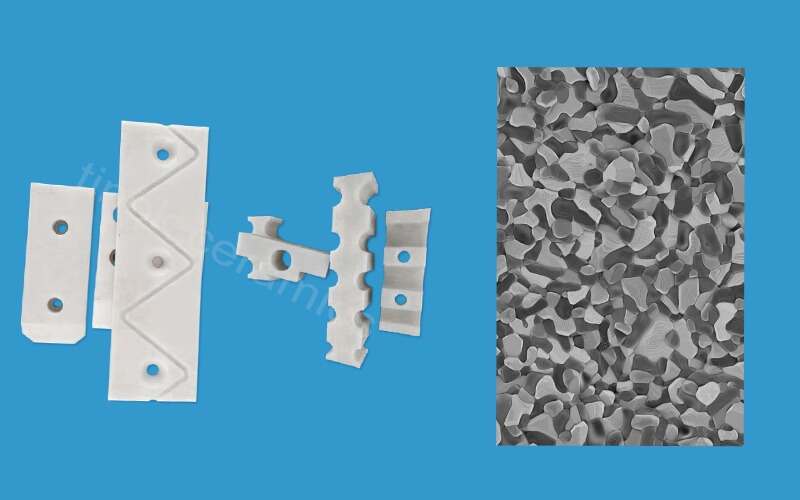

1. Control the gas and impurities in the preparation process: Controlling the gas and impurities content in the material during the preparation process can reduce the possibility of porosity formation.

2. Increase the sintering temperature: Increase the sintering temperature and strengthen the control of the sintering cycle during the sintering process, which can also reduce the possibility of porosity formation.

3. Add thermal shock resistant materials: Adding thermal shock resistant materials during the preparation process can improve the temperature stability during the sintering process and reduce the formation of pores.

Alumina ceramic is a kind of high performance material, but it has a lot of porosity in the process of processing, which affects its quality and performance. The formation of pores is caused by the gas and impurities in the material, the non-uniformity of the preparation process, and the sintering temperature is not high enough. To solve the problem of many pores, we can control the gas and impurities in the preparation process, increase the sintering temperature and strengthen the control of sintering cycle, and add thermal shock resistant materials. These methods can effectively reduce the porosity of alumina ceramics and improve its quality and performance.