The most complete summary of the ten structural ceramic component forming processes

Ceramic component forming is an important part of the ceramic preparation process, the forming technology to a large extent determines the uniformity of the body and the ability to prepare complex shaped parts, and directly affects the reliability of the material and the cost of the final ceramic parts.

Comparison of various molding techniques

Molding Method | Molding Material | Product Shape | Uniformity |

Dry Pressing | Granulated Powder | Flat Shape | Deviation |

Cold Isostatic Pressing | Granulated Powder | Round Tube Cylindrical Sphere | Good |

Casting Molding | Slurry | Complex Shape | Large Size |

Film Casting | Slurry | <1mm Thick Cross-section | Good |

Gel Molding | Slurry | Complex Shape | Thick Cross-section |

Direct Solidification Injection Molding | Slurry | Complex Shape | Thick Cross-section |

Extrusion Molding | Plastic Material | Cylindrical | Long Size Products |

Hot Press Casting | Viscoelastic Material | Complex Shape | Small Size |

Injection Molding | Viscoelastic Material | Complex Shape | Small Size |

Ceramic component molding process can be roughly divided into the following aspects: grouting molding, plastic molding, pressing molding. The above various forming methods, forming principles and processes are different, so the characteristics are different, each has advantages and disadvantages. The selection of ceramic component forming method should be determined according to the performance requirements, shape, size, output and economic benefits of the product. So, today we will briefly introduce the ten forming methods of these ceramic components.

Dry press molding

Dry press molding, also known as die molding, is one of the most commonly used molding methods. Dry press forming is to load the powder with good granulation, good fluidity and suitable particle gradation into the metal mold cavity, apply pressure through the indenter, and the indenter displaces in the mold cavity to transfer the pressure, so that the powder particles in the mold cavity are rearranged and compacted to form a ceramic blank with certain strength and shape.

Main factors affecting dry press forming:

(1) Powder properties: particle size, particle size distribution, fluidity, moisture content, etc.;

(2) Selection of binders and lubricants;

(3) Mold design;

(4) Pressing force, pressure mode, pressure speed and pressure holding time in the pressing process.

In summary, if the billet particle size is suitable, the binder is used correctly, and the pressure method is reasonable, the dry pressing method can also obtain an ideal billet density.

Advantages of dry pressing:

(1) Simple process, convenient operation, short cycle, high efficiency, easy to implement automated production.

(2) The body density is large, the size is accurate, the shrinkage is high mechanical strength, and the electrical performance is good.

Disadvantages of dry pressing:

(1) It is difficult to produce large billets, the mold wear is large, the processing is complicated, and the cost is high.

(2) The pressure can only be pressurized up and down, the pressure distribution is not uniform, the density is not uniform, the contraction is not uniform, will produce cracking, delamination and other phenomena. However, with the development of modern molding methods, this shortcoming has gradually been overcome by isostatic pressing.

Application: It is especially suitable for the preparation of ceramic component products with small section thickness, such as ceramic sealing ring, ceramic valve core for valves, ceramic liner, ceramic lining, etc.

Casting molding

Casting molding is also known as scraper molding. Its basic principle is to flow the ceramic paste with appropriate viscosity and good dispersion from the blade edge of the casting machine to the base band, spread the paste through the relative movement of the base band and the scraper, and form a smooth upper surface of the blank film under the action of surface tension, the thickness of the blank film is mainly controlled by the gap between the scraper and the base band. The blank film enters the drying chamber with the base band, and the solvent evaporates the organic binder to form a network structure among the ceramic particles, forming a blank with a certain strength and flexibility. After the dry blank is peeled off from the base band, the scroll is ready for use. It can then be cut to the desired shape, punched or punched, and finally sintered to obtain the finished product.

The casting process can be divided into non-water based casting, water based casting, gel casting and so on.

The process of ceramic substrate preparation by casting process includes slurry preparation, casting process, drying, degreasing and sintering, among which the most critical process is slurry preparation and casting process control.

Advantages: The casting molding can prepare several microns to 1000μm smooth ceramic sheet material, and the equipment is simple, the process is stable, can be continuously operated, easy to automation, high production efficiency, product performance is consistent, so it is the most important and effective process for the preparation of single or multi-layer sheet material.

Disadvantages: The binder content is high, so the shrinkage rate can reach 20% to 21%.

Applications: monolithic capacitor tiles, thick film and thin film circuit Al2O3 substrate, piezoelectric ceramic diaphragm, structural ceramic component sheet, capacitor, thermistor, ferrite and piezoelectric ceramic body, hybrid integrated circuit substrate, etc.

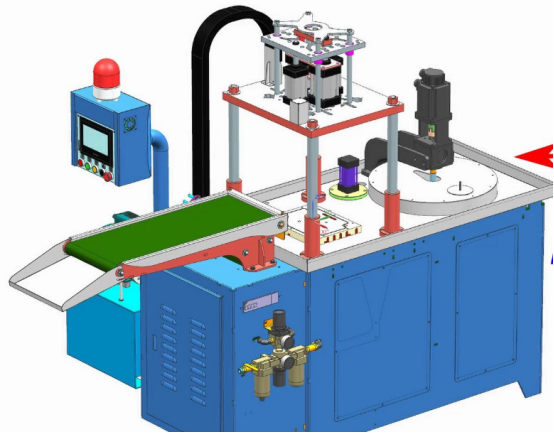

Injection molding

Ceramic injection molding is a new process for preparing ceramic parts, which is developed by combining polymer injection molding with ceramic preparation technology.

The manufacturing process of ceramic injection molding mainly includes four links:

(1) Preparation of injection feed: mixing, drying and granulating suitable organic carrier and ceramic powder at a certain temperature to obtain injection feed;

(2) Injection molding: the injection mixture after mixing is heated into a viscous melt in the injection molding machine, injected into the metal mold at a certain temperature and pressure at a high speed, cooled and solidified into the desired shape of the billet, and then demoulded;

(3) degreasing: by heating or other physical and chemical methods, the organic matter in the injection molding body is removed;

(4) Sintering: the ceramic blank after degreasing is densified and sintered at high temperature to obtain the dense ceramic parts with the required appearance shape, dimensional accuracy and microstructure.

Advantages of injection molding:

(1) It can be formed directly into small ceramic parts with complex geometric shapes and special requirements, so that the sintered ceramic products do not need to be machined or processed less, thereby reducing the cost of expensive ceramic processing.

(2) The degree of mechanization and automation is high, the forming cycle is short, only tens of one to a few hundredths of the pouring and hot pressing forming time, the strength of the blank is high, can be automated production, the management and control of the production process is also convenient, suitable for mass production.

(3) Due to the good fluidity of the binder, the density of the injection forming billet is quite uniform.

(4) Because the mixture of powder and binder is very uniform, the gap between the powder is small, and the shrinkage characteristics during the sintering process are basically the same, the density of each part of the preparation is uniform, and the geometric size accuracy and surface finish are high.

Application: This technology is the most advantageous for the mass production of ceramic products with high dimensional accuracy and complex shapes. At present, ceramic injection molding has been widely used in various ceramic powders and various engineering ceramic products. Various precision ceramic parts prepared by this process have been used in aviation, automobile, machinery, energy, optical communication, life medicine and other fields.

Isostatic pressing

At present, isostatic pressing is the main forming method for producing alumina ceramic balls.

Hot isostatic pressing process is to apply high pressure (50-200MPa) and high temperature (400-2000℃) to the outer surface of the machined parts by inert gas (such as argon or nitrogen), the increased temperature and pressure make the material through plastic flow and diffusion to eliminate the gap under the surface. The hot isostatic pressing process can achieve a uniform and fast cooling process through thin-wall prestressed winding units, and the production efficiency is increased by 70% compared with the natural cooling process.

The cold isostatic pressing process can apply higher pressures to ceramic or metal powders, up to 100-600 mpa at room temperature or slightly higher temperatures (<93 ° C), to obtain "green" parts with sufficient strength to be treated and machined, and sintered to final strength. Hot isostatic pressing and cold isostatic pressing technologies allow ceramic manufacturers to increase productivity while controlling material properties.

Introduction to hot isostatic pressing technology

Hot isostatic pressing technology appeared in the early 1950s, and since then, many applications have been very optimistic about this technology. Hot isostatic pressing technology is a production process of densification casting, from the consolidation of metal powder (such as metal injection molding, tool steel, high-speed steel), to the compaction of ceramics, and then to additive manufacturing (3D printing technology) and other applications, hot isostatic pressing technology can be seen.

Currently, about 50% of hot isostatic pressing units are used for the consolidation and heat treatment of castings. Typical alloys include Ti-6Al-4V, TiAl, aluminum, stainless steel, nickel superalloys, precious metals (such as gold, platinum), as well as heavy metals and refractory materials (such as molybdenum, tungsten). Due to the increasing interest in ceramic additive manufacturing in the aerospace and automotive sectors in recent years, hot isostatic pressing will be able to rapidly expand more applications in the future.

First, the hot isostatic component needs to be heated under elevated pressure or vacuum, while the gas is introduced in advance to expand it and effectively establish the pressure atmosphere in the hot isostatic furnace, and this start-up procedure depends on the material composition and hot isostatic pressure cycle.

The pressure applied in hot isostatic pressure with pure argon is generally between 100-200 mpa. However, other gases such as nitrogen and helium are sometimes used, while gases such as hydrogen and carbon dioxide are rarely used. Sometimes combinations of different gases are used. Both lower and higher pressures can be used in some special areas, and it is ultimately up to the application field to determine which gases should be used for which purposes. Because helium, argon and nitrogen are relatively expensive, and hydrogen is explosive at the wrong concentration, special attention should be paid when using.

The main advantages of hot isostatic pressing technology are: increase product density, improve product mechanical properties, improve production efficiency, reduce scrap rate and loss. After hot isostatic pressing treatment, the internal pore defects can be repaired, the design is lighter, the product has better ductility and toughness, the performance fluctuation is reduced, the service life is longer (relying on alloy system, the fatigue life of the part is increased by nearly 10 times), and the metallurgical bonding (diffusion bonding) can be formed between different materials.

Cold isostatic pressing technology introduction

Cold isostatic pressing uses a liquid medium, such as water or oil or glycol mixtures, to apply pressure to the powder. The powder is placed in a fixed shape mold that prevents the liquid from penetrating the powder. For metals, the cold isostatic pressing technique can achieve a theoretical density of about 100%, while more difficult to compress ceramic powders can achieve a theoretical density of about 95%.

The extremely high pressure makes the void in the powder smaller or even disappear, under high pressure, the metal powder deformation due to its ductility, ceramic powder may be slightly broken, the density can be increased, and finally form a "green" part that can be processed, processed and sintered. The typical pressure range is 100-600 mpa, the temperature is usually room temperature, and if higher temperatures are required, the heat exchanger can raise the temperature to about 93 ° C. However, since the temperature of water increases when it is compressed, about 4 ° C for every 100MPa increase, the risk of boiling at higher temperatures increases.

Density variation of metal and ceramic powders

Common applications of cold isostatic pressing include consolidation of ceramic powders, graphite, refractories, electrical insulators, and compression of advanced ceramics. Materials include silicon nitride, silicon carbide, boron nitride, boron carbide, titanium boride, spinel, etc. The technology is expanding into new applications, such as the pressing of sputtering targets, the coating of valve parts used to reduce cylinder wear in engines, telecommunications, electronics, aerospace and automotive.

Cold isostatic pressing technology has the following advantages: improve the degree of consolidation of products, increase the mechanical properties of products, relatively centralized production data, more safe control of production, very low corrosion, high efficiency and low cost.

The decompression process in the cold isostatic pressing process also determines the quality of the "green" block. Because the metal or ceramic powder is compacted, the gas is trapped between the particles, and the pressure increases during processing as the externally applied pressure increases. The metal block has very high strength and ductility, and will naturally release the trapped air after the cold isostatic pressing process.

However, because the ceramic "green" compacts are more brittle, if the pressure is released too quickly and in an uncontrollable manner, the ceramic compacts are likely to break in places where air cannot escape. The way to avoid this is to release the applied pressure in a controlled manner by fine-tuning the pressure relief system, which is especially important at lower pressures, when the applied pressure is equal to the internal gas pressure, and the trapped air can affect the internal stress.

Illustration of air entrainment in ceramic powder

At present, cold isostatic pressing technology is widely used in daily ceramics, architectural ceramics, special ceramics and other fields. For example, plates, dishes, alumina grinding balls, alumina chemical packing balls, firebricks, ceramic sticks, spark plugs, high-frequency porcelain sleeves, composite ceramics, etc.

Usually referred to as isostatic pressing refers to cold isostatic pressing, which is a method of using fluid (water, oil) as a transfer medium to obtain uniform static pressure applied to the material. That is, the incompressibility of the liquid medium is used to transfer the pressure uniformly, and the pressure is applied from all directions to obtain the molding method of the product. According to its forming process, it can be divided into two forms: wet bag type and dry bag type. At present, the wet bag method is mainly used in large quantities.

1, wet bag type isostatic pressure

Wet bag isostatic pressing technology is to place granulated ceramic powder or pre-formed billet into a deformable rubber envelope, and then apply uniform pressure in all directions through the liquid. When the pressing process is over, the rubber envelope containing the billet is removed from the container, which is a discontinuous forming method.

The cost of this technology is relatively low, it can form moderately complex parts, and the pressure can reach 500MPa, which is suitable for small-scale production, but the number of molded products is small in a certain period of time, the size and shape of the compact are not accurately controlled, the production efficiency is not high, and the large-scale production cannot be continuous.

2, dry bag type isostatic pressure

Dry bag isostatic pressing is to fill a batch of ceramic powder into the flexible preform mold, and then apply isostatic pressing, because the mold is fixed to the device, when the pressing is completed, the formed product is pushed out, as shown in the diagram.

Dry bag isostatic pressing has short molding cycle and long mold life, which is especially convenient for large-scale continuous chemical industry production. The mold material used is polyurethane synthetic rubber or silicone rubber. Compared with wet bag isostatic pressing, dry bag isostatic pressing pressure is lower, generally within 200MPa. The most familiar ceramic spark plug is currently formed by dry bag isostatic pressing, and the pressing time is usually only 1~2s.

Advantages of isostatic pressing:

(1) The pressure is transmitted from all directions, the compact density is evenly distributed, and the compact strength is high;

(2) The density of the blank is high, the uniform defect is less, and the firing shrinkage is lower than the general dry pressure;

(3) It can press parts with concave shape, slender parts and other complex shapes;

(4) small friction loss, low molding pressure;

(5) Low mold cost.

Disadvantages of isostatic pressing: the size and shape of the compact is not easy to accurately control, the productivity is low, and it is not easy to achieve automation;

Applications:

(1) Wet isostatic pressing technology is used for large thin-wall, high-precision, high-performance alumina ceramic radome and large wall thickness, complex shape, and 97% alumina ceramic high frequency terminal insulation porcelain sleeve with umbrella edge.

(2) 95% alumina ceramic vacuum switch arc extinguishing chamber "shell" series products, alumina and zirconia ceramic plungers, and large size zirconia ceramic cylinder liner for oil drilling use isostatic pressure technology.

(3) Transparent alumina ceramic tubes and alumina spark plugs for high-pressure sodium lamps generally use dry bag isostatic pressing technology.

Grouting molding

Grouting molding is a very simple and flexible molding technology, its basic principle is to have a high phase content and good fluidity of the slurry into the porous mold (usually gypsum grinding tool), because the mold porosity has a capillary suction, the mold wall absorbs water from the slurry to form a solidified body along the mold wall. When the blank body forms a certain strength, the mold can be removed.

The basic process flow is: powder → slurry → grouting → demoulding → drying → billet

The main process methods of slurry molding are: hollow grouting, solid grouting, pressure grouting, vacuum auxiliary grouting, centrifugal grouting.

Advantages:

(1) The use of cheap plaster mold, simple equipment, low cost, suitable for complex shape ceramic parts and large size ceramic products manufacturing;

(2) Convenient molding process control and high product density.

Application: traditional ceramic industry, modern precision ceramics, structural ceramic components products, etc

Extrusion molding

Extrusion molding, also known as extrusion molding or extrusion molding, the process is to mix ceramic powder with clay or organic binder and water that can provide plasticity and repeated mixing, and through vacuum degassing and stale process links to obtain good plasticity and uniformity of the billet to be extruded, and then under the action of the extrusion screw or plunger, The product of the desired shape is extruded through the die at the mouth of the extruder.

Extrusion molding requirements for mud:

(1) Powder fineness and shape: fineness requirements are finer, the shape is rounded, and it is better to grind the powder of the ball for a long time.

(2) solvents, plasticizers, binders, etc. : the amount should be appropriate, and the mud must be highly uniform, otherwise the quality of the extruded body is not good.

Advantages of extrusion molding:

(1) Small pollution, easy to operate automation, continuous production, high efficiency.

(2) Suitable for the production of tubular and rod products. But the structure of the nozzle is complicated and the machining precision is high.

Disadvantages: Due to the large number of solvents and binders, the body shrinks greatly during dry firing, and the performance is affected. It is easy to have defects such as warping deformation, layered structure, tearing, cracking, solid-liquid separation, pores and inclusions.

Application: Extrusion molding is suitable for the manufacture of ceramic products with uniform cross section, especially for tubular or rod-shaped products with high aspect ratio, and can be used for the molding of various oxide ceramics, carbides and nitrides and other non-oxide ceramic products.

At present, it is widely used in the preparation of ceramic furnace tube, electromagnetic insulator, catalyst carrier or support body, heat exchanger tube, honeycomb ceramic carrier for automobile exhaust filter, ceramic sticks and other ceramic products, and can also be used in the molding of chip capacitors, magnetic material substrate and electronic substrate.

Hot die casting molding

Hot die casting is to make use of the characteristics of paraffin wax melting and cold solidification, the non-plastic and finless ceramic powder is evenly mixed with hot paraffin liquid to form a flowing slurry, which is injected into the metal mold under a certain pressure to form, and the molded body is removed after cooling until the wax paste solidifies. The body is properly trimmed, buried in the adsorbent and heated for dewaxing treatment, and finally burned to form the final product.

The difference between hot die casting and general grouting molding method:

It does not use solvents, but uses the high-temperature rheological properties of the binder - paraffin wax, casting under pressure, and then dewaxing and sintering at high temperatures to make ceramics.

Advantages:

(1) Can shape complex shape ceramic products, high dimensional accuracy, almost no need for follow-up processing, is the main molding process for the production of special-shaped ceramic products;

(2) The equipment is cheap, the mold wear is small, the production cost is relatively low;

(3) Easy operation, little labor intensity, high production efficiency;

(4) Strong applicability to raw materials, such as oxides, non-oxides, composite raw materials and various mineral raw materials can be applied.

Disadvantages: high wax content of slurry, low molding pressure, easy to lead to low product density, long wax discharge time.

(1) High porosity, relatively more internal defects, low density, mechanical properties and performance stability of products are relatively poor;

(2) Dewaxing is required, which increases energy consumption and production time. Due to the limitation of dewaxing, it is difficult to prepare thick wall products.

(3) Not suitable for the preparation of large size ceramic products;

(4) It is difficult to manufacture high-purity ceramic products, which limits the application of the process in the field of high-end technology.

Application: Engineering ceramic parts with various complex shapes.

Gel injection molding

Gel injection molding is a new ceramic molding technology invented in recent years. In this method, the ceramic powder is first dispersed in a solution containing organic monomers to prepare a suspension with a high solid phase volume fraction (> 50%), and then injected into a mold with a certain shape. Under certain catalytic and temperature conditions, the organic monomers are polymerized and the system gels, resulting in in-situ solidification of the suspension, and finally, a high strength billet can be obtained after drying.

In the process of changing from liquid to solid, the body does not shrink or shrink very little, and the amount of medium does not change. It can manufacture complex shape ceramic parts with a net size, has good uniformity and high strength of the body, the operation process is simple, the content of organic impurities in the body is less, and the performance of the ceramic sintered body is excellent.

Gel injection molding is divided into two categories: one is water-soluble gel injection molding, and the other is non-water-soluble gel injection molding. The former is suitable for most ceramic forming occasions, and the latter is mainly suitable for the forming of systems that react with water.

Advantages:

(1) Strong ability to apply ceramic powder, no special requirements for powder;

(2) can achieve near-net size molding, can prepare large size and complex shape and wall thickness parts, mold can choose a variety of materials;

(3) The forming cycle is short, the strength of the wet and dry billet is high, which is obviously better than the billet made by the traditional forming process, and can be machined;

(4) Low organic content in the body;

(5) Good uniformity of performance of billet and sintered body;

(6) The process is easy to control;

(7) The process and operation are relatively simple, simple equipment and low cost.

Cons:

(1) Defects such as bubbles and cracks may occur during the molding and drying process;

(2) Toxicity of organic monomers.

Applications: coarse particle system ceramics, high-grade refractory materials, ceramic composite materials, structural ceramic components, functional and bioceramics, porous materials and powder metallurgy, etc.

Direct solidification injection molding

Direct solidification injection molding is a new type of ceramic net size colloidal forming method that integrates colloidal chemistry and ceramic process. This technology mainly uses biological enzymes to catalyze the corresponding reaction substrate in ceramic slurry, and chemical reactions occur, thereby changing the PH value of the slurry or compressing the double electric layer, so that the repulsive force between solid particles in the slurry is eliminated, resulting in van der Waals attraction. However, the ceramic paste with high solid content and low viscosity poured into the non-porous mold produces original solidification, and the ceramic wet blank after solidification has enough strength for demoulding.

Advantages:

(1) The forming process does not require or only requires a small amount of organic additives (less than 1%), non-toxic, so the body can be directly sintered without degreasing;

(2) The body structure is uniform, the relative density is high (generally up to 55%~65%), and the ceramic parts with high accuracy and complex shape can be formed;

(3) Wide selection of mold materials and low mold cost.

Cons:

(1) The range of forming ceramic powder is limited;

(2) The strength of the ceramic body is relatively low, and it cannot be processed as a blank.

Application: It can be used in the preparation of oxide ceramics, non-oxide ceramics, multiphase composite ceramics, etc.

Solid molding

The basic principle and process of solid freeform fabrication (SFF) are as follows: directly using the results of computer CAD design, complex three-dimensional components were sliced and divided by computer software to form computer executable pixel unit files. Then through the external equipment output by the computer, the ceramic powder to be formed quickly into the actual pixel unit, and the result of superposition of one unit can be directly formed into the required three-dimensional components.

At present, SFF technology has developed into the following 6 types:

(1) laser selective sintering method;

(2) layer superposition forming method;

(3) melting cover forming method;

(4) three-dimensional printing forming method;

(5) 3D printing forming method;

(6) Inkjet printing forming method.

Compared with traditional molding methods, solid rapid formless molding technology has the following advantages:

(1) There is no need for any mold or model to participate in the molding process, making the process more integrated, shortening the manufacturing cycle, and improving efficiency;

(2) The geometry and size of the molding body can be changed at any time through the computer software processing system, without waiting for the design and manufacture of the mold, shortening the development time of new products;

(3) Because the size of the external molding printed pixel unit can be as small as the micron level, it can be prepared for the life science and small satellite miniature electronic ceramic devices;

(4) The combination of modern intelligent technology to further improve the level of ceramic preparation industry, so that this field matches the progress of other industrial manufacturing fields.

Cons:

(1) The equipment price is high, the stratification of the equipment and the software is strong, and there is no universal system software;

(2) The density and molding performance of the molding material are not ideal, and the quality and accuracy of the parts often cannot meet the needs;

(3) The material technology has patent protection, and the general molding materials are more expensive.

Applications: mechanical manufacturing, polymer materials, ceramics, etc