The key technology of connecting metal and ceramic parts

The coefficient of thermal expansion of metal is large, and the coefficient of thermal expansion of ceramic parts is small, so it is difficult to achieve packaging. With the maturity of technology, the key technology of sealing metal and ceramic parts is mature. The application is also more extensive, and today us will share what keyword technology is to achieve the success of sealing ceramic parts and metal.

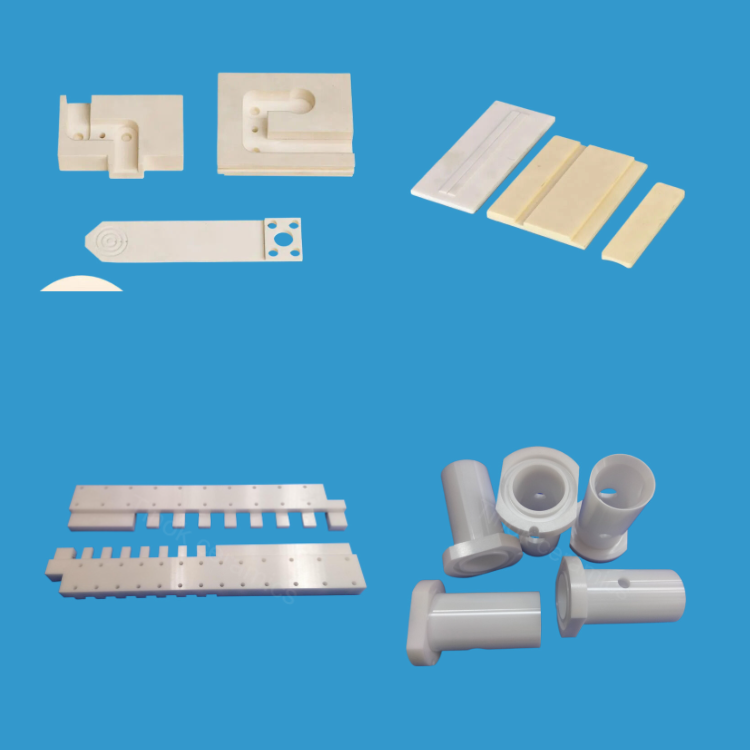

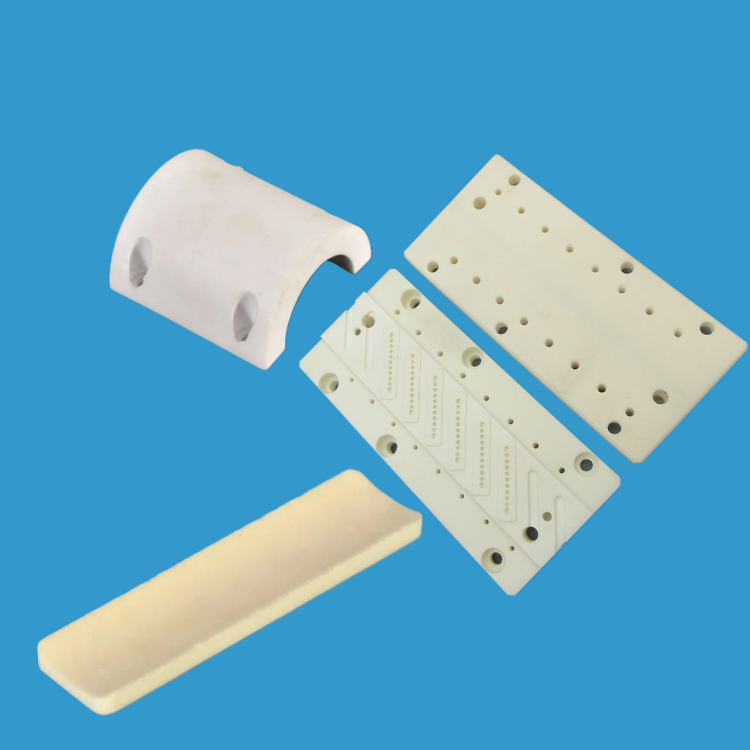

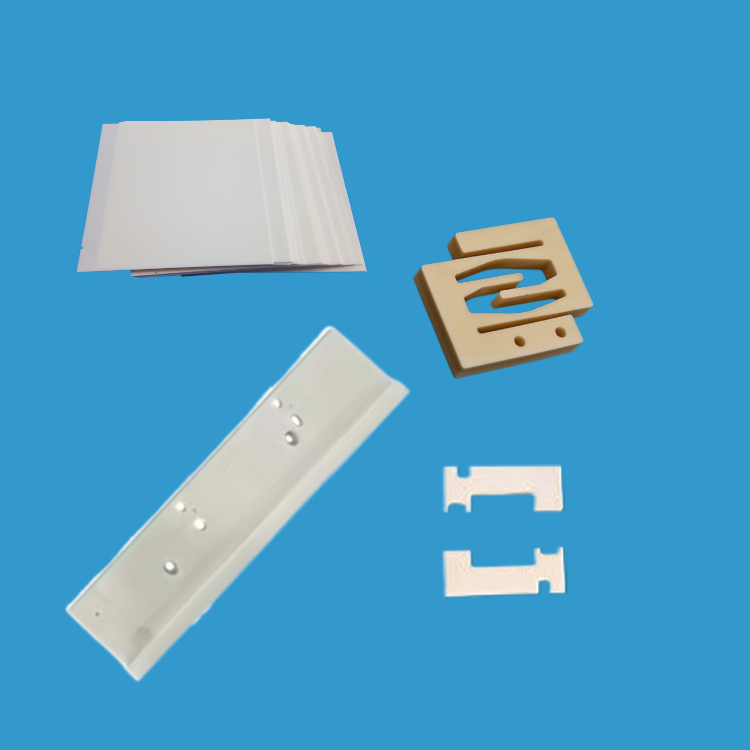

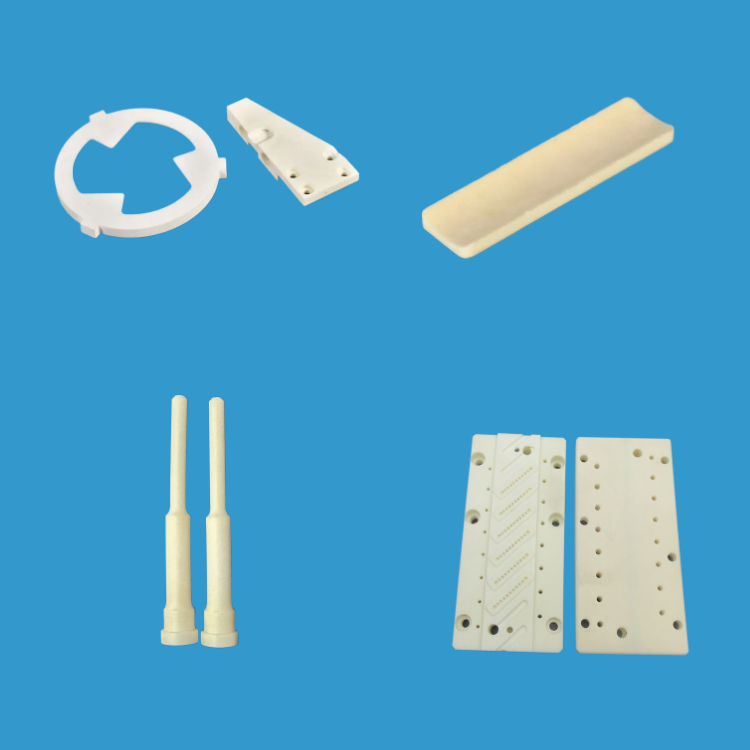

Market application of ceramic parts and metal connection devices

Ceramic parts and metal connectors in new energy vehicles, electronic and electrical, semiconductor packaging and IGBT modules and other fields have a wide range of applications, its products are mainly ceramic parts structure and ceramic parts substrate, due to the increase in market demand and new materials continue to emerge, Such as ceramic parts relays, ceramic parts sealing connectors, ceramic parts substrate and other products to achieve large-scale industrialization, therefore, with high strength, high air tightness, high reliability of ceramic parts and metal sealing process is crucial.

Technical difficulties of sealing ceramic parts with metal

1, the linear expansion coefficient of ceramic parts is small, and the linear expansion coefficient of metal is relatively large, resulting in joint cracking. Generally, the thermal stress of the metal interlayer should be dealt with well.

2, the ceramic parts themselves have low thermal conductivity and weak heat shock resistance. During welding, the temperature gradient in and around the welding site should be reduced as much as possible, and the cooling rate should be controlled after welding.

3, most of the ceramic parts have poor electrical conductivity, or even do not conduct electricity, it is difficult to use electric welding methods.

4, because the ceramic parts material has a stable electronic coordination, making the connection of metal and ceramic parts is unlikely. Ceramic parts need to be metallized or brazed with active brazing metal.

5, because the ceramic parts are mostly covalent crystals, it is not easy to produce deformation, often brittle fracture. At present, most of the intermediate layer is used to reduce the welding temperature and indirect diffusion method for welding.

6, the structural design of ceramic parts and metal welding is different from that of ordinary welding, which is usually divided into flat seal structure, sleeve seal structure, pin seal structure and sealing structure, of which the sleeve seal structure has the best effect, and the production requirements of these joint structures are high.

Requirements for sealing metal and ceramic parts:

Good ceramic parts and metal sealing, the sealing should meet the following requirements:

1.With good vacuum air tightness, the printing should not be lost at high temperature;

2. Has a certain mechanical strength;

3. Under the condition that the working temperature is higher for a long time, the electrical and mechanical properties should remain unchanged;

4. Can withstand sharp temperature changes;

5. The process is simple and suitable for mass production;

6. The tolerance of the sealing size should be small.

Mechanism and process flow of metallization of ceramic parts

1. Metallization mechanism of ceramic parts

The mechanism of metallization of ceramic parts is complicated, involving several chemical and physical reactions, plastic flow of substances, particle rearrangement and so on. Various substances such as oxides and non-metallic oxides in the metallized layer have different chemical reactions and material diffusion and migration in different sintering stages. With the increase of temperature, all substances react to form intermediate compounds, and form liquid phase when they reach the common melting point. The liquid glass phase has certain viscosity, and plastic flow occurs at the same time. After that, particles rearrange under the action of capillary, atoms or molecules diffuse and migrate under the drive of surface energy, grains grow, pores gradually shrink and disappear. The densification of the metallized layer is achieved.

2, Ceramic parts metallization process

The process of metallization of ceramic parts includes:

The first step: matrix pretreatment. The non-pressure sintered ceramic parts are thrown to optical smooth with diamond grinding paste to ensure that the surface roughness is less than 1.6m. The substrate is placed in acetone and alcohol, and cleaned by ultrasonic wave at room temperature for 20min.

Step 2: Preparation of metallized slurry. According to the metallization formula, the raw material is weighed and the metallization paste with a certain viscosity is made after a certain time of ball milling.

Step 3: Paint, dry. The use of screen printing technology on the ceramic parts substrate coated with slurry, slurry thickness should be appropriate, too thin solder easy to flow into the metallization layer, too thick is not conducive to component migration, and then the sizing matrix in the oven drying.

Step 4: Heat treatment. The dried matrix was sintered in a reducing atmosphere to form a metallized layer.

Ceramic parts and metal sealing key technology 5 key technologies

l Specific methods for metallization of ceramic parts

The commonly used preparation methods for metallization of ceramic parts include Mo-Mn method, activated Mo-Mn method, active metal brazing method, direct copper coating method (DBC) and magnetron sputtering method.

1. Mo-Mn method

Mo-mn method is based on refractory metal powder Mo, and then add a small amount of low-melting point Mn metallization formula, add a binder coating to the surface of Al2O3 ceramic parts, and then sintering to form a metallized layer. The disadvantages of the traditional Mo-Mn method are high sintering temperature, high energy consumption, and low sealing strength due to the absence of activator in the formula.

2, activation Mo-Mn method

Activated Mo-Mn method is an improvement on the basis of traditional Mo-Mn method, and the direction of improvement mainly includes adding activator and replacing metal powder with molybdenum and manganese oxides or salts. Both of these improvements are designed to reduce the metallization temperature.

The disadvantage of the activated Mo-Mn method is that the process is complex and the cost is high, but its combination is firm and can greatly improve the wettability, so it is still the earliest, most mature and most widely used process in the ceramic parts - metal sealing process.

3, active metal brazing method

Active metal brazing method is also a more widely used ceramic parts - metal sealing process, it is 10 years later than the development of Mo-Mn method, is characterized by fewer processes, ceramic parts - metal sealing only need a heating process to complete. Brazing alloys contain active elements, such as Ti, Zr, Hf and Ta, the added active elements react with Al2O3 to form a reaction layer with metal characteristics at the interface, this method can be easily adapted to large-scale production, compared with molybdenum-manganese process, this method is relatively simple and economical.

The disadvantage of the active metal brazing method is that the active filler metal is single, which causes its application to be limited to a certain extent, and it is not suitable for continuous production, but only suitable for large, single piece production or small batch production.

4, direct copper application method (Directbondedcopper, DBC)

DBC is a metallization method of bonding copper foil on the surface of ceramic parts (mainly Al2O3 and AlN), which is a new process developed with the rise of chip on board (COB) packaging technology. The basic principle is to introduce oxygen between Cu and ceramic parts, and then form Cu/O eutectic liquid phase at 1065 ~ 1083℃, and then react with the matrix of ceramic parts and copper foil to form CuAlO2 or Cu(AlO2)2, and realize the bonding between copper foil and matrix under the action of the intermediate phase.

5. Magnetron sputtering (DPC)

Magnetron sputtering is a kind of physical vapor deposition, which is to deposit multilayer films on the substrate through magnetic control technology, which has advantages over other deposition technologies, such as better adhesion, less pollution and improved crystallinity of the deposited sample, to obtain high-quality films.

The metallization layer obtained by this method is very thin and can ensure the accuracy of the size of the part, but it is not suitable for the metallization of ceramic parts that are not resistant to high temperature (such as piezoelectric ceramic parts and single crystals).

Influencing factors of metallization of ceramic parts

1. Metallization formula

This is the premise to realize the metallization of ceramic parts, and it is necessary to make careful and scientific design of its formula.

2, metallization temperature and holding time

Another key factor affecting the metallization of ceramic parts is the metallization sintering temperature and holding time. The metallization temperature can be divided into the following four processes: the temperature above 1600 ° C is extremely high temperature, 1450~1600 ° C is high temperature, 1300~1450 ° C is medium temperature, and the temperature below 1300 ° C is low temperature. The appropriate sintering temperature is necessary, too low temperature will cause the glass phase does not produce diffusion and migration, too high metallization strength is relatively poor, the metallization layer is easy to fall off from the ceramic parts resulting in the failure of sealing.

3. Microstructure of metallized layer

The metallization process determines the microstructure of the metallized layer, and the microstructure directly affects the final properties of the welded body. In order to obtain good weldability, the first metallized layer should be a dense film with high bonding strength. If each region of the microstructure of the metallized layer is clearly layered, and no continuous brittle metal compound is observed at any interface, the probability of brittleness and crack growth will be reduced, and the interface is tight with fewer cracks, which is conducive to reducing solder penetration, indicating that the metallized layer has good densification and relatively high bonding strength.

4. Other factors

There are many factors that affect the degree of metallization of ceramic parts that need to be paid attention to, such as the influence of powder particle size and reasonable grading, the powder is too fine, the surface can be large, and it is easy to form agglomeration, which will affect the flatness of the coating; If the powder is too coarse, the surface energy will be reduced, resulting in increased sintering temperature and affecting sintering quality. In addition, the coating method and the thickness of the coating will also have a great impact on the metallization of ceramic parts.

The above is about the sealing of metal and ceramic parts key introduction, I believe you have a more profound understanding of the metallization process of ceramic parts, the specific use of which process on the one hand needs to be processed according to the customer's custom requirements