What is the tensile strength of the ceramic rod bar

The tensile strength of ceramic bars is generally between 200-600MPa.

What is the tensile strength of ceramic rods?

Ceramic rod is a common ceramic parts, and its tensile strength refers to the tensile strength that the rod can withstand during the stretching process. The tensile strength is one of the important parameters to measure the tensile strength of the bar, and also one of the indexes to judge its quality.

The tensile strength of the ceramic rod is generally how much?

The tensile strength of ceramic bars is generally between 200-600MPa. The tensile strength of different kinds of ceramic rods with different processing technology is different. Generally , the tensile strength of ordinary ceramic rods is low, while the tensile strength of high-performance ceramic rods is relatively high.

Standard for tensile strength of zirconia ceramics rod

The tensile strength standard of zirconia ceramics usually refers to its breaking strength. At present, the tensile strength standards of zirconia ceramics at home and abroad are not completely consistent, and their common standards are as follows:

1. ISO 6872: The breaking strength of zirconia ceramics is 800-1200MPa.

2. JIS R1601: The breaking strength of zirconia ceramics is 600MPa and above.

3. ASTM F1875: The minimum breaking strength of zirconia ceramics is 900MPa.

It should be noted that different application fields have different tensile strength requirements for zirconia ceramic rods, so the standards are also different.

Factors affecting the tensile strength of zirconia ceramics

The tensile strength of zirconia ceramic rods is not only affected by its own material properties, but also by the following factors:

1. Preparation process: During the preparation of zirconia ceramics, temperature, time, pressure and other factors will affect its tensile strength.

2. Material purity: The presence of impurities will affect the grain boundary structure of zirconia ceramics, reducing its strength.

3. Grain size: The size of the grain size will also affect the strength of zirconia ceramic rods, the smaller the grain, the higher the strength.

4. Surface quality: The surface quality of zirconia ceramics also has a great impact on its tensile strength.

5. Stress state: Compared with tensile stress, zirconia ceramics have higher strength under compressive stress.

Tensile strength of alumina ceramic rods

Alumina ceramic rod has excellent wear resistance and high temperature properties, and high tensile strength. According to the experimental data, the tensile strength of conventional alumina ceramic rod can reach more than 300MPa, and the tensile strength of high-strength alumina ceramic rod can reach more than 500MPa. At the same time, alumina ceramic rods are also very hard and perform well in terms of friction and wear.

What is the tensile strength of silicon carbide rod

The tensile strength of silicon carbide is usually 150-300MPa.

The basic concept and characteristics of silicon carbide

Silicon carbide (SiC) is an important refractory and electronic material, which has excellent thermal properties, chemical stability and mechanical strength, so it is widely used in many fields. Silicon carbide hardness is extremely high, reaching the gem level, can maintain high hardness at high temperatures for a long time, while the oxidation resistance is good.

Silicon carbide tensile strength information

The tensile strength of silicon carbide is usually 150-300 mpa (mpa). Although this value is lower than that of some metal materials, in harsh environments such as high temperature and high pressure, silicon carbide can still maintain good tensile properties, so it is widely used in some special fields, especially in high temperature and high pressure fields. In addition, silicon carbide can also improve its tensile strength by controlling the crystal structure, which has a broad application prospect.

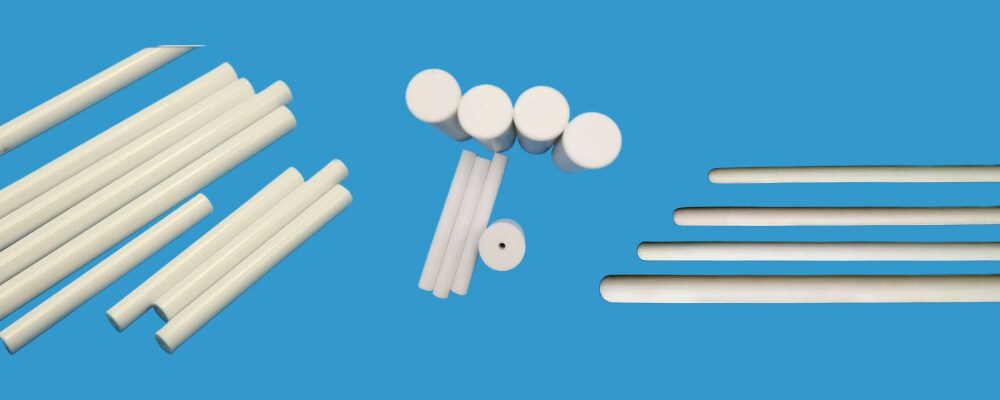

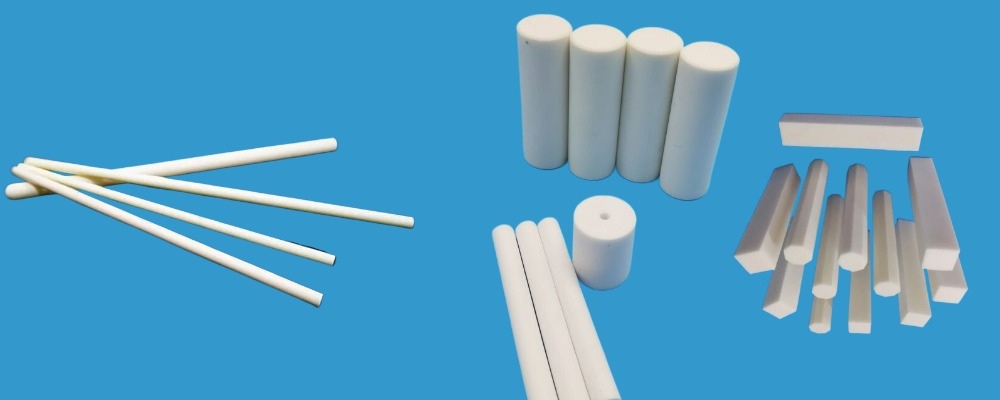

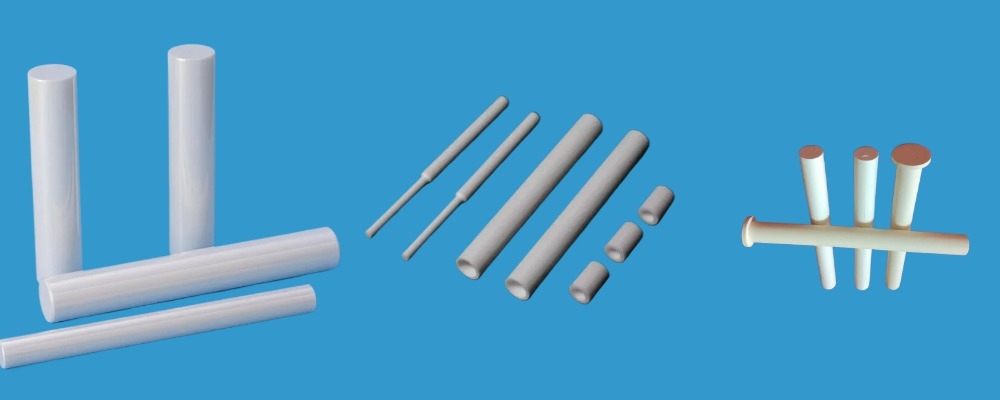

The application of ceramic rods

Ceramic rods are widely used in industrial production because of their excellent wear resistance, high temperature resistance and corrosion resistance. For example, ceramic rods are often used in the manufacture of mechanical parts, the processing of precision instruments, and the manufacture of aluminum oxide electrolytic cell supports. In addition, ceramic rods can also be made into electronic ceramic components, ceramic crafts and so on.

Conclusion

the tensile strength of ceramic rod and its general value range, and also describes the application of ceramic rod in industrial production. Through the introduction of this article, I believe that readers have a more comprehensive understanding of the performance characteristics of ceramic rods.