Research on thermal and thermal insulation characteristics of alumina ceramics

Alumina ceramics have excellent thermal conductivity, but they can also achieve thermal insulation by adjusting their structure, depending on the application scenario and preparation process.

Alumina ceramics, as a kind of material with a wide application prospect, its thermal conductivity and thermal insulation properties have been the focus of attention. Before understanding its properties, we first need to clarify the basic concepts of thermal conductivity and thermal insulation. Thermal conductivity refers to the ability of a substance to transfer heat, while thermal insulation is the process that prevents heat transfer. The performance of alumina ceramics in these two aspects depends on its material structure, density, grain size and other factors.

In terms of thermal conductivity, alumina ceramics are known for their high melting point, high hardness, good thermal stability and chemical stability. These characteristics make alumina ceramics have excellent thermal conductivity in high temperature environments, which can effectively transfer heat and improve the thermal efficiency of the equipment. In addition, the thermal conductivity of alumina ceramics can also be optimized by adjusting its preparation process and doping other elements to meet the needs of different application scenarios.

However, alumina ceramics are not only thermal conductivity, it also has a certain application potential in heat insulation. By adjusting the porosity, porosity structure and thickness of alumina ceramics, the thermal conductivity can be effectively reduced, so as to achieve the heat insulation effect. This characteristic makes alumina ceramics have a wide application prospect in the fields of thermal insulation and heat insulation.

Of course, the application of alumina ceramics in thermal insulation also has certain limitations. Due to its excellent thermal conductivity, more complex structural design and preparation processes are needed to achieve the ideal thermal insulation effect. In addition, the cost of alumina ceramics is also relatively high, which limits its wide application in the field of thermal insulation to a certain extent.

In summary, alumina ceramics not only have excellent thermal conductivity, but also can achieve thermal insulation effect under specific conditions. Its nature is closely related to the application scenario, and it needs to be selected according to the actual demand. In the future, with the continuous optimization of the preparation process and the research and development of new alumina ceramics, it is believed that its application in the field of heat conduction and heat insulation will be more extensive and in-depth.

Why can alumina ceramics both heat insulation and heat conduction?

In our common sense, thermal insulation materials and thermal conductivity materials seem to be two distinct things. For example, cotton is insulated and can be made into cotton-padded clothes; Iron conducts heat and is used as a wok. Not the other way around. However, in reality, we can often see another phenomenon, that is, the same material can be used in two seemingly opposite scenes of heat preservation and heat conduction. For example, alumina ceramics are like this, which can be made into heat-insulating bricks and used in high-temperature furnaces; It can also be made into a radiator and used in electronic products such as LED lights.

Supposedly, as a thermal insulation material, the requirement is low thermal conductivity; As a heat dissipation material, high thermal conductivity is required. Can the thermal conductivity of the same material change at any time?

To answer this question, there are two ways to look at it.

The first aspect, indeed like the question raised above, the thermal conductivity of the material will change. The most typical is that the thermal conductivity is different at different temperatures. Take alumina as an example, as the temperature increases, the thermal conductivity will continue to decline. The thermal conductivity at 1200 ° C is about half that at 400 ° C. However, the thermal conductivity of alumina is not small, 20-30W/m•K at room temperature, that is, it falls by more than half, and almost 10W/m•K, which is higher than the thermal conductivity of many materials. Therefore, this change does not seem to be large enough to explain why alumina can be both thermal and thermal insulation, and more convincing reasons are needed.

Therefore, we have to look at the second aspect, which is also the main aspect: aluminum oxide can be both heat insulation and heat conduction, because of structural changes. That is to say, when alumina ceramics are used as thermal insulation materials and thermal conductivity materials, their internal structure is not the same.

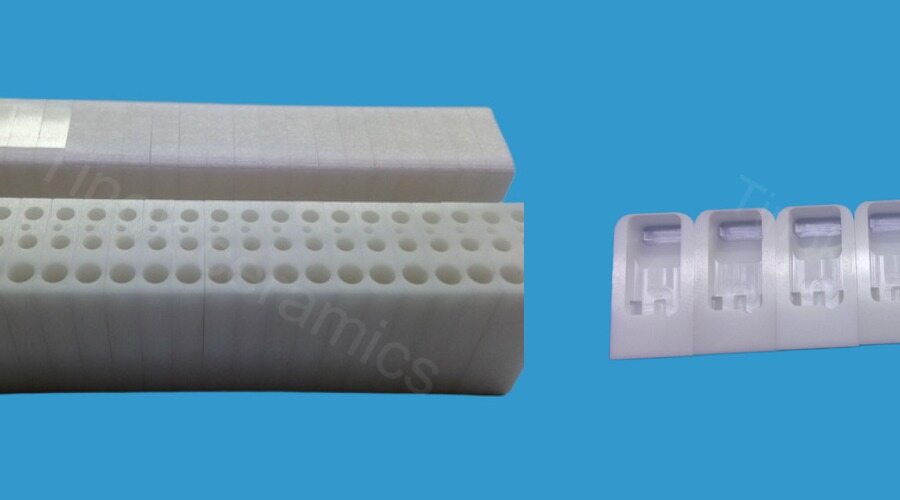

Alumina foam ceramics

When alumina ceramics are used as thermal insulation materials, the biggest feature of their structure is porosity and low density. For example, make alumina hollow spherical bricks. As we all know, the thermal conductivity of air is very low, so the thermal conductivity of alumina hollow brick is also very low. Some people may ask, since the thermal conductivity of air is very low, it is simply to use air insulation, why bother, the air to alumina material? This is because although the thermal conductivity of air is very low, it cannot prevent thermal radiation, just as the thermal conductivity of vacuum is zero, and the heat of the sun is still transmitted to the Earth through the vacuum. The porous alumina not only blocks the heat conduction, but also blocks the heat radiation, so it can effectively play the role of heat insulation. It has been publicly reported that an alumina microporous ceramic has a density of only 0.6g/cm3, a porosity of 85%, and a thermal conductivity of only 0.3W/m•K at 1200℃.

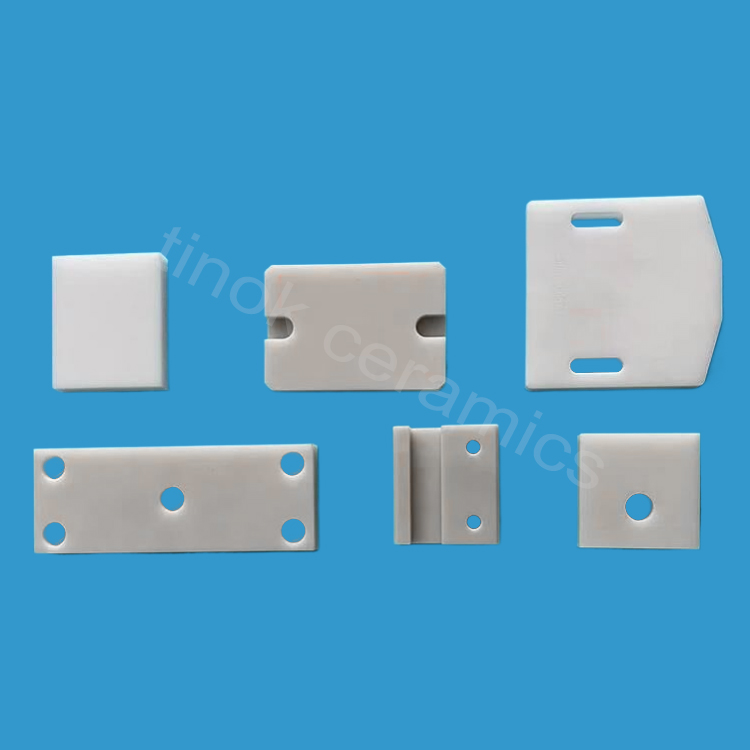

But when aluminum oxide is made into heat-conducting ceramics, the requirements are completely different. The first requirement is that the density should be high, the higher the better. High density, fewer pores, ceramic grains close together, convenient heat conduction. The second requirement is that the purity should be high, the higher the purity, the higher the thermal conductivity. For example, the thermal conductivity of ceramics with 99% alumina content can reach ~26W/m•K, and when the alumina content drops to 95%, the thermal conductivity is only ~20W/m•K. This is because in ceramics with low alumina content, the composition of the glass will be relatively high, and the thermal conductivity of the glass is relatively low, which results in the overall thermal conductivity of the ceramic is relatively low. Of course, in practical applications, you have to consider the cost. Although high purity alumina ceramics have high thermal conductivity, the price is also high. Therefore, according to the needs of the product to choose alumina ceramics, can not blindly pursue high purity.

Alumina ceramic LED light

In addition to high purity and dense structure, alumina ceramics used as a radiator often have specific requirements for its external shape, such as made of LED radiator, often with fin structure, to increase the surface area, convenient heat to air escape, so as to achieve better heat dissipation effect.