Zirconia ceramic composition

Mineral composition and structure of zirconia ceramic material

Zirconia ceramics are mainly composed of zirconia (ZrO2), and stabilizers such as yttrium oxide (Y2O3) are often added to improve their performance. Its features include high temperature stability, high strength and excellent corrosion resistance.

Zirconia ceramic, as an advanced structural ceramic material, has been widely used in many fields because of its unique physical and chemical properties. So, what are the components of zirconia ceramics? Below, we will reveal them all.

Main ingredients: Zirconia (ZrO2)

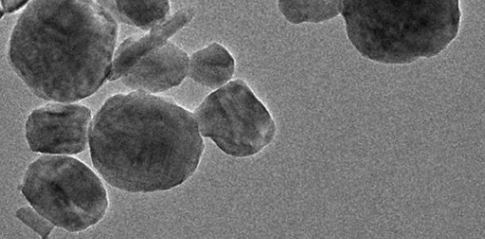

Zirconia is the cornerstone of zirconia ceramics, accounting for the vast majority of its composition. ZrO2 has a high melting point (about 2700°C), excellent hardness and good chemical stability, making it an ideal raw material for the preparation of high-performance ceramics. However, pure zirconia at room temperature has monoclinic, tetragonal and cubic crystal transformation, these transformations are often accompanied by volume changes, easy to lead to ceramic cracking. Therefore, in practical applications, this phase transition is usually inhibited by adding stabilizers.

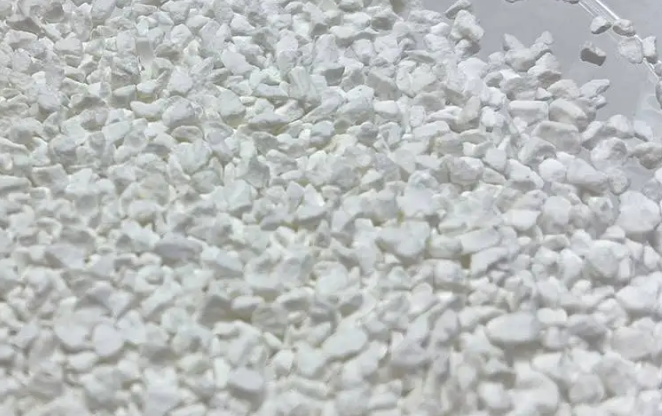

In most cases, the content of zirconia will exceed 90%, which is also the basis for the excellent performance of zirconia ceramics. Zirconia is a white odorless, tasteless crystal with a high melting point and high chemical stability, thus giving zirconia ceramics high hardness, high strength and good corrosion resistance.

The addition of stabilizer: the key to improve performance

In order to improve the performance of pure zirconia ceramics, a variety of stabilizers have been developed, of which yttrium oxide (Y2O3) is the most commonly used. The addition of Y2O3 can effectively stabilize the tetragonal or cubic phase of zirconia to prevent its phase transition when the temperature changes, thereby improving the thermal stability and mechanical strength of the ceramics. In addition, calcium oxide (CaO), magnesium oxide (MgO) and other commonly used stabilizers, they have their own characteristics, can be selected according to specific needs.

Other additives

In addition to zirconia, a number of other oxides may be added to zirconia ceramics to regulate the properties of the ceramics or achieve specific functions.

1. Alumina (Al2O3) : The addition of alumina can improve the hardness and wear resistance of ceramics, while reducing the sintering temperature, which helps to save energy and reduce costs.

2. Yttrium oxide (Y2O3) : Yttrium oxide is commonly used as a stabilizer to form a solid solution with zirconia, thereby stabilizing the crystal structure of zirconia and improving the thermal shock resistance and mechanical properties of ceramics.

Other rare earth oxides: such as cerium oxide (CeO2), lanthanum oxide (La2O3), etc., the addition of these rare earth oxides can further improve the high temperature properties, electrical properties and optical properties of ceramics.

Excellent properties of zirconia ceramics

1. High temperature stability: Because zirconia ceramics with stabilizer can maintain a stable crystal structure at high temperatures, it has excellent high temperature stability and is suitable for a variety of high temperature environments.

2. High strength: Zirconia ceramics have extremely high hardness and fracture toughness, and its strength can even be comparable to some metals, which is the ideal material for manufacturing high-wear and high-bearing parts.

Excellent corrosion resistance: ZrO2 has strong chemical stability and can resist the erosion of a variety of acids, alkalis and oxidizing media, so it has a wide range of applications in chemical, medical and other fields.

Crystal structure and application of zirconia ceramics

Zirconia has three crystal forms at room temperature and pressure: monoclinic, tetragonal and cubic. Different crystal types have different physical and chemical properties, so in practical applications, in order to meet specific needs, people will add different types of stabilizers to prepare zirconia ceramics with specific crystal types. These ceramic materials have a wide range of applications in structural ceramics, in the manufacture of ornaments, and in medical fields such as the manufacture of teeth or bone joints.

To sum up, zirconia ceramics with its unique composition and excellent performance, in modern science and technology and industry play a pivotal role. With the continuous progress of material science and the increasing perfection of process technology, it is believed that the application field of zirconia ceramics will be more extensive and make greater contributions to the development of human society.