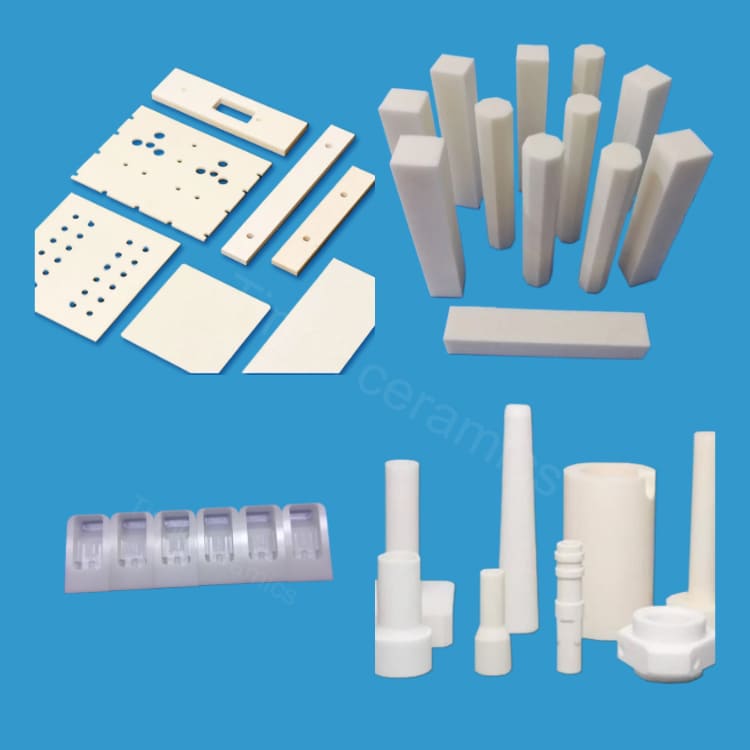

corrosion resistant ceramic part high chemical stability corrosion anti precision ceramic components

Corrosion resistant ceramic parts are inorganic non-metallic ceramic materials, the main components of silicon dioxide, alumina, zirconia and other compounds. Due to its dense material, chemical stability and high hardness, the first characteristic of ceramics is its good corrosion resistance. In general, ceramic materials can perform excellent corrosion resistance in acid and base, so that it is widely used in electronics, aviation, environmental protection and other fields.

Surface corrosion resistance of ceramic parts

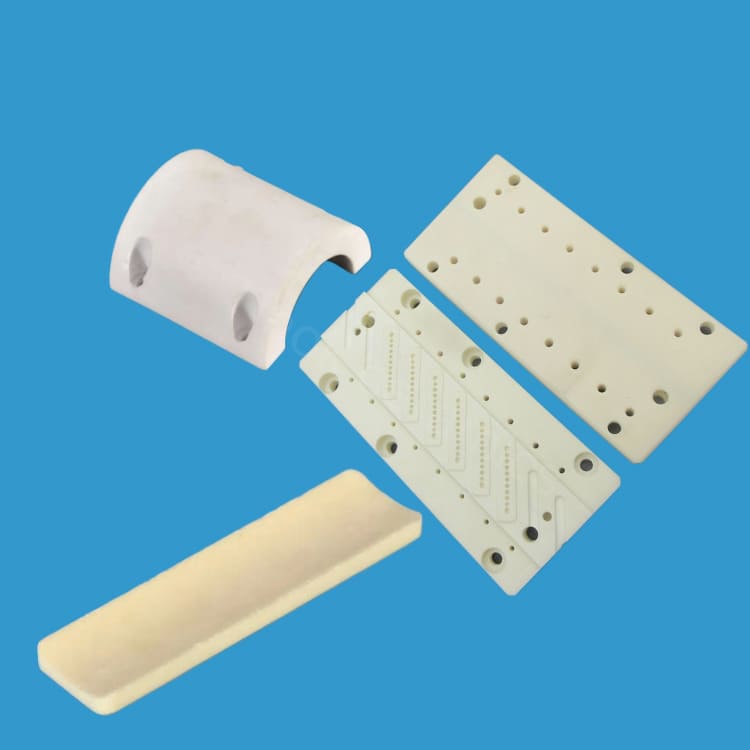

The surface properties of corrosion resistant ceramic parts are also important factors affecting their corrosion resistance. The surface of corrosion resistant ceramic parts is generally after high temperature sintering, polishing and surface treatment and other processes, forming a dense, smooth surface, its surface morphology and chemical properties determine the way and strength of its interaction with the corrosive medium.

The surface of corrosion resistant ceramic parts is rich in active functional groups, which can chemically react with corrosive media such as acids, bases and oxidants to generate compounds or oxides that are insoluble in corrosive media, so as to protect the material from corrosion. In addition, there are also some polar functional groups in the structure of corrosion resistant ceramic parts, which can form electrostatic fields on the surface, affecting the adsorption and ion exchange of corrosive media, and further enhancing the corrosion resistance of the material.

1. Chemical corrosion

The chemical inertia of corrosion resistant ceramic parts makes it show good corrosion resistance to common corrosive media such as acids, alkalis and organic solvents, and it will not be corroded even if it is immersed in the irritating liquid environment for a long time.

2. Electrochemical corrosion

The electrical conductivity of corrosion resistant ceramic parts is very low, there are few spontaneous electrochemical reactions and corrosion reactions, and it is difficult to form a primitive reaction to electrochemical corrosion, so it can resist various electrochemical corrosion media.

3. Thermal corrosion

corrosion resistant ceramic parts have high thermal deformation temperature, can be used in high temperature environment for long-term stability, not affected by oxidation, vulcanization and other high temperature vapor phase medium, so the corrosion resistance in high temperature environment is very prominent.

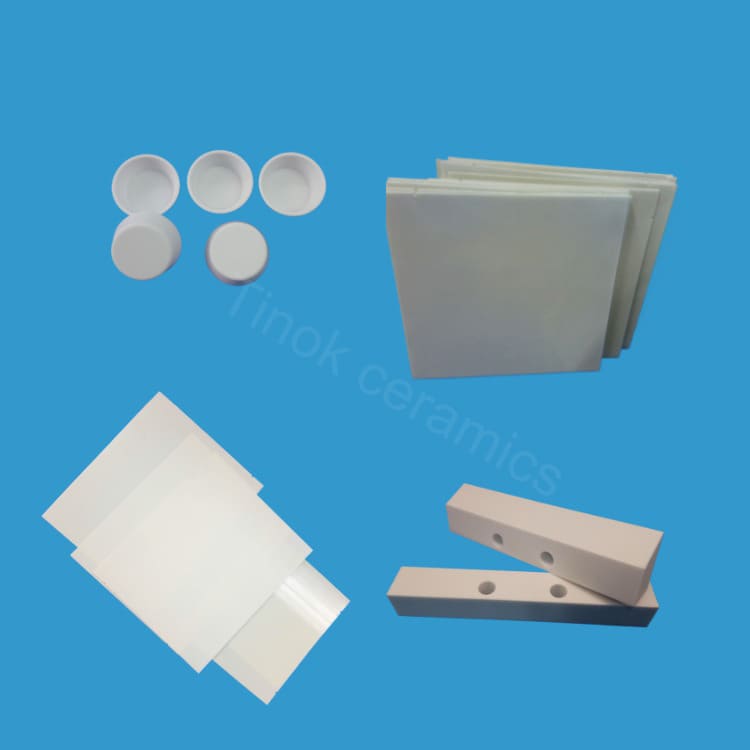

Application of corrosion resistant ceramic parts in the field of corrosion

corrosion resistant ceramic parts are widely used in the field of corrosion, for example, in chemical reactions, the storage and transportation of reagents require the use of acid-resistant and alkali-resistant ceramic vessels, and ceramic materials are also needed in the production of electrolytes, because corrosion resistant ceramic parts do not produce oxidation in these chemicals, which can better protect their chemical properties. Similarly, in the machinery industry, many mechanical parts also need to use ceramic materials for manufacturing, corrosion resistant ceramic parts can greatly reduce the corrosion and damage of corrosion resistant ceramic parts caused by chemical reactions.