Other ceramics

Silicon carbide ceramics (SiC)

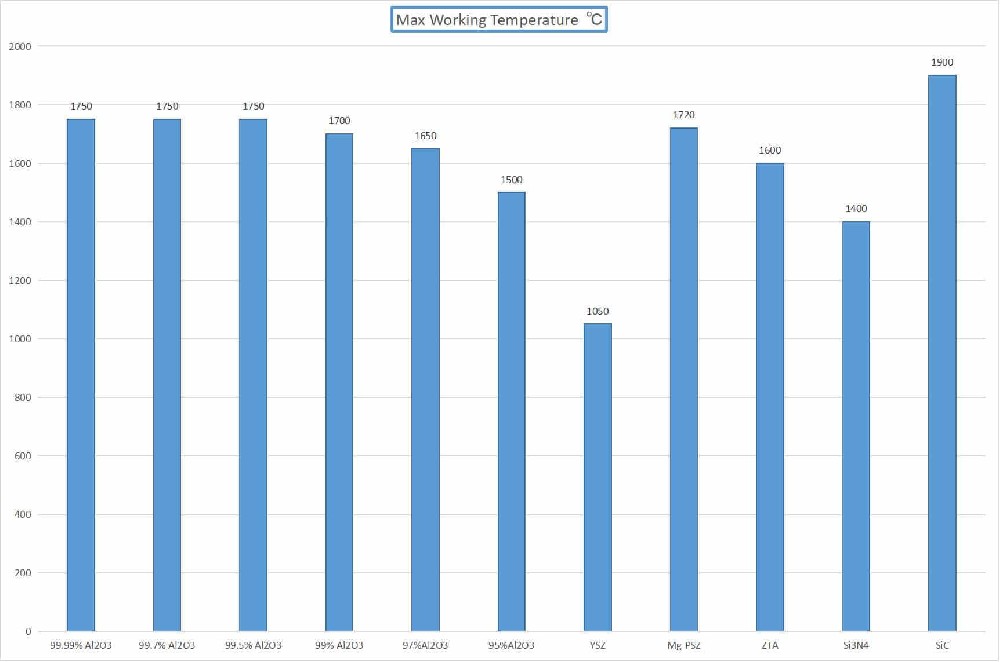

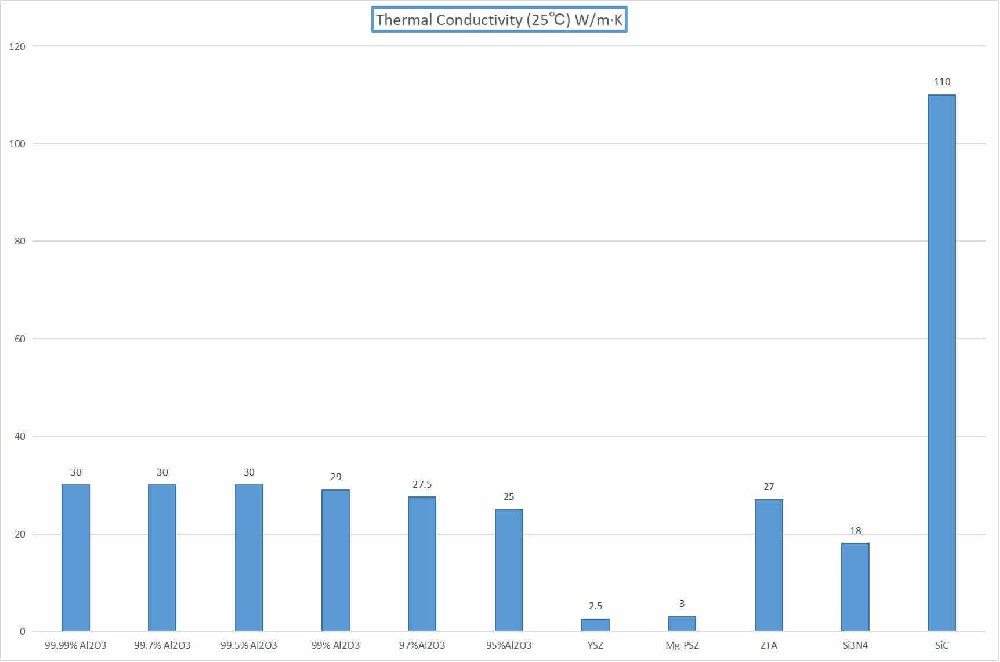

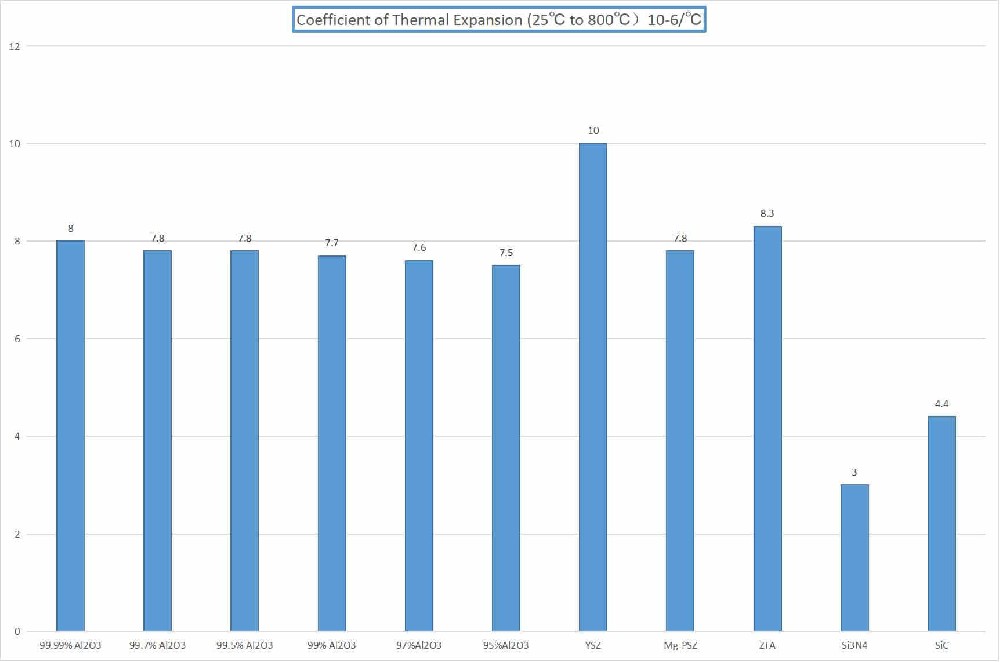

The main component of silicon carbide ceramics is SiC, which is a kind of high strength, high hardness of high temperature ceramics, 1200℃~1400℃ can still maintain high bending strength, is the highest high temperature strength of ceramics, silicon carbide ceramics also have good thermal conductivity, oxidation resistance, electrical conductivity and high impact toughness. It is a good high-temperature structural material, which can be used for rocket nozzle, thermocouple sleeve, furnace tube and other parts working at high temperature. The thermal conductivity can be used to make heat exchange materials at high temperatures; Use its high hardness and wear resistance to make grinding wheels, abrasives and so on.

Hexagonal boron nitride ceramics (BN)

Hexagonal boron nitride ceramics are mainly composed of BN, the crystal structure is hexagonal crystal system, hexagonal boron nitride structure and performance are similar to graphite, so it is called "white stone ink", low hardness, can be cut with self-lubricating, can be made of self-lubricating high-temperature bearings, glass forming molds.

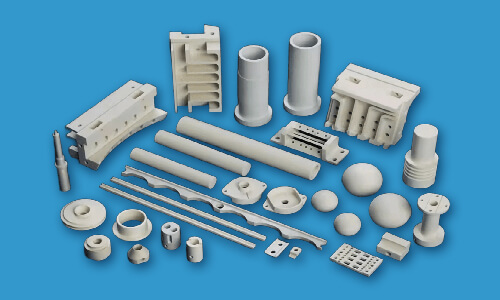

Special ceramics used as structural components. It is composed of single or composite oxides or non-oxides, such as single Al2O3, ZrO2, SiC, Si3N4, or composite with each other, or combined with carbon fiber. It is used in the manufacture of ceramic engines and special components for wear resistance and high temperature resistance.

Structural ceramics can be divided into three categories: oxide ceramics, non-oxide ceramics and composite ceramics.

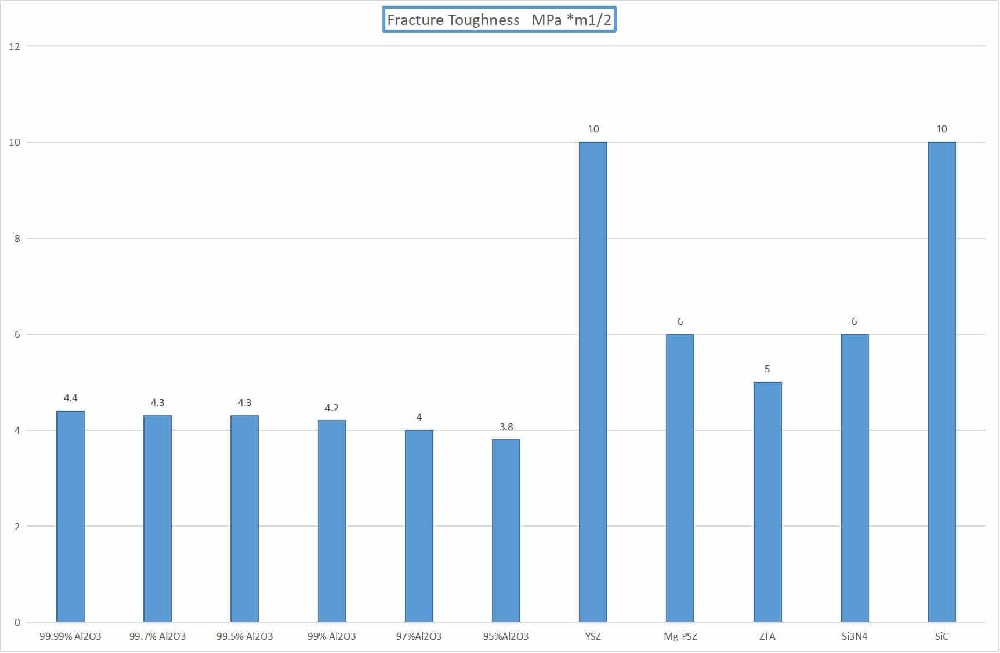

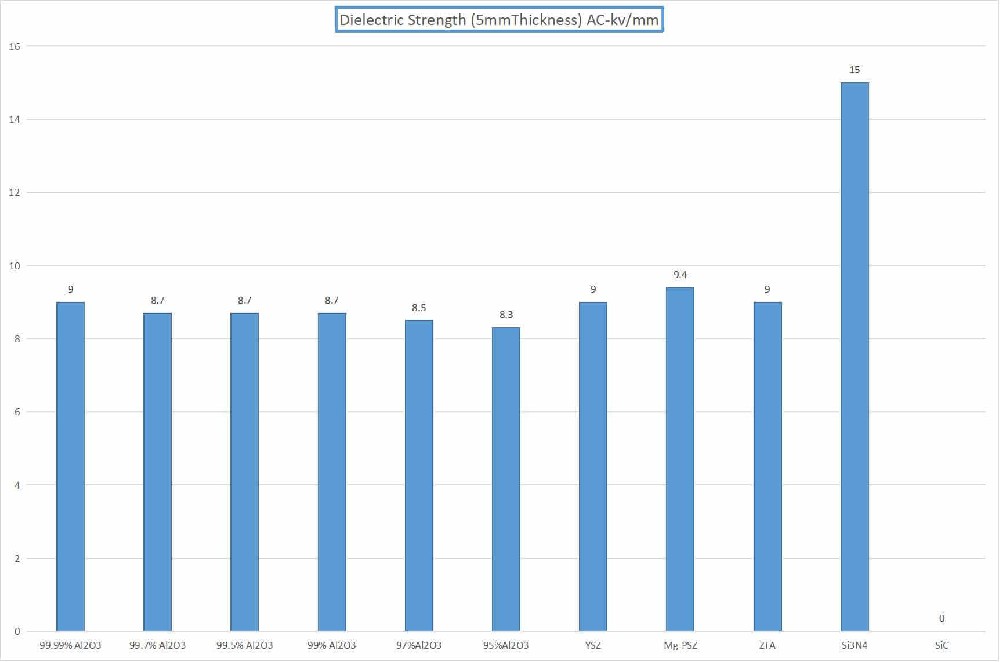

1. Oxide ceramics: Oxide ceramics, as the name suggests, are mainly composed of oxides, such as alumina, zirconia and so on. Oxide ceramics have high hardness, high toughness, high strength, high temperature stability, wear resistance, corrosion resistance, heat shock resistance and other characteristics, and its performance will not change significantly under high temperature and pressure. Oxide ceramics are widely used in aviation, machinery, electronics, medical and other fields.

2. Non-oxide ceramics: Non-oxide ceramics are composed of boron compounds, carbon compounds, nitrogen compounds, etc., common silicon boride, silicon carbide, silicon nitride, boron nitride, titanium carbide and so on. Non-oxide ceramics have the characteristics of high temperature, high hardness, high strength, thermal shock resistance, wear resistance, etc., compared with oxide ceramics, it also has better electrical and thermal conductivity. Non-oxide ceramics are widely used in aviation, optoelectronics, engineering, energy and other fields.

3. Composite ceramics: composite ceramics is a new material prepared by combining two or more kinds of materials, and its main components are generally oxide ceramics, non-oxide ceramics, metals, carbon, etc. Composite ceramics have the advantages of single ceramic and single metal, such as crack resistance, good wear resistance, high thermal stability, excellent thermal conductivity, corrosion resistance and so on. Composite ceramics can meet the needs of high-end fields such as aluminum electrolysis, special mixing, petrochemical industry, etc.