Zirconia ceramics(ZrO2)

Zirconia is a material with high mechanical strength and high fracture toughness at room temperature, and its thermal expansion coefficient is similar to that of metal, which is ideally suitable for combination with metal materials. Zirconia has relatively fine grain, which can complete high coarse-processing, and its excellent biocompatibility is also widely used in the biomedical industry.

According to the added stabilizer, zirconia ceramics are mainly divided into yttrium stabilized zirconia, magnesium stabilized zirconia, and cerium stabilized zirconia. Among them, magnesium stabilized zirconia still maintains good mechanical properties at higher temperatures (600℃).

Zirconia ceramics are inorganic nonmetallic materials with excellent physical properties and high density, which are mainly divided into thermal physical properties, mechanical properties and chemical stability. At present, there are many molding processes for zirconia ceramics, such as dry pressing, hot die casting, injection molding, injection molding, isostatic pressing, etc., among which the ceramic parts of isostatic pressing are the best.

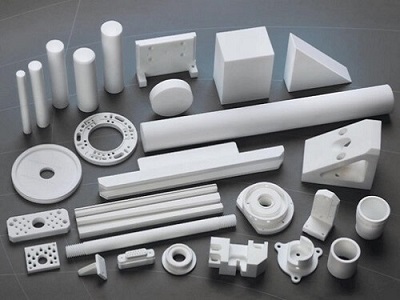

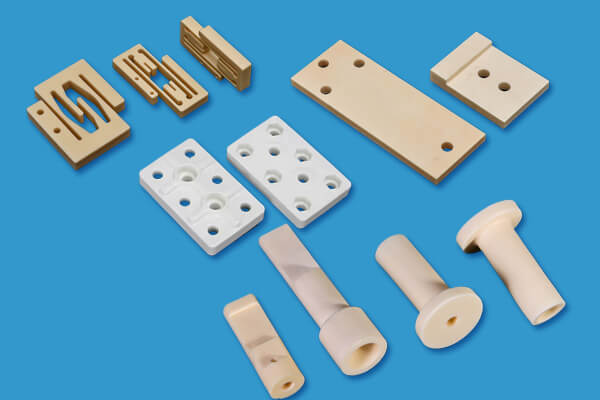

Related Zirconia ceramic part products

Tinok Precision Ceramics offers high quality Zirconia ceramic accessories. A variety of Zirconia ceramic processing methods, including machining or net forming, can be applied to produce parts of various sizes and shapes. In addition, it can be easily attached to metals or other ceramics using metallization and brazing techniques...

Advantages

The mechanical properties of zirconia ceramics also show very good performance. Due to its high density and density, it shows very high compressive strength when subjected to pressure, and has good fracture toughness, so in the manufacture of precision industrial parts, processing tools, abrasives, etc., have shown good application performance.

- Unmatched strength and toughness: Zirconia ceramics have high bending strength, fracture toughness and Vickers hardness, making them one of the strongest ceramic materials, which makes them ideal for demanding applications requiring wear resistance.

- Excellent hardness: zirconia ceramic Mohs hardness of about 8.5, is one of the hardest materials, its scratch resistance and wear resistance can even be comparable to steel.

- Remarkable chemical inertia: Zirconia ceramics are resistant to a variety of chemicals and are not affected by corrosive environments, making them ideal for demanding industrial applications.

- Excellent heat insulation: due to low thermal conductivity, zirconia ceramics perform well in heat insulation applications, can reduce heat transfer and improve energy efficiency, suitable for insulation applications.

- Lightweight design: Although zirconia ceramics have impressive strength and hardness, it is still very light, providing the perfect combination of rugged performance and easy handling.

Applications

Zirconia (ZrO2) has a high melting point, oxidation resistance and high temperature resistance, has a very high use temperature, and is a ceramic material with excellent toughness, so it is often used in high temperature resistant parts, mechanical wear parts, and other steel combined structural parts.

- wear-resistant structural parts. Using zirconia high strength, high toughness, wear resistance, corrosion resistance characteristics, can be prepared for oil drilling ceramic cylinder liner, pump ceramic valve and ball valve. In addition, it can also prepare nozzles, ceramic grinding rings and other products.

- Ceramic core and sleeve (optical fiber connector connector)

- Engine parts (engine combustion chamber cylinder head bottom plate, cylinder liner, piston top). The thermal conductivity of zirconia ceramics is small, and the thermal expansion coefficient is relatively large, so it is used to make parts of the engine combustion chamber. It has a good heat insulation, while in the thermal expansion and metal material is closer.

- Solid electrolyte materials (for high temperature fuel cells)

- High temperature heating element. Zirconia ceramic is a kind of high temperature solid electrolyte, which is a conductor of oxygen ions and has the property of conducting oxygen ions. At the same time, it also has good characteristics of impermeable oxygen and other gases and liquid metals such as steel, so it is used as a high temperature heating element.

- Metallurgical high-temperature application (refractory crucible). Zirconia is a weakly acidic oxide, which can resist the erosion of acidic or neutral slag.

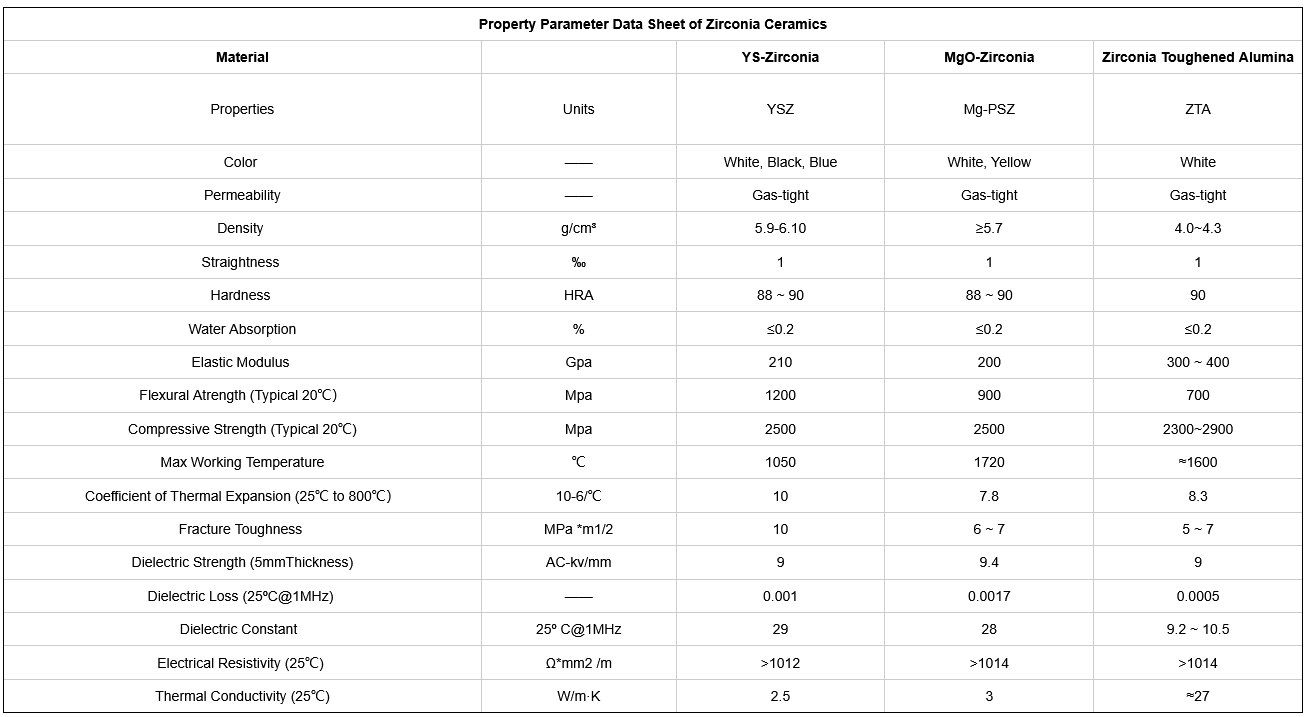

Zirconia Material Properties

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)