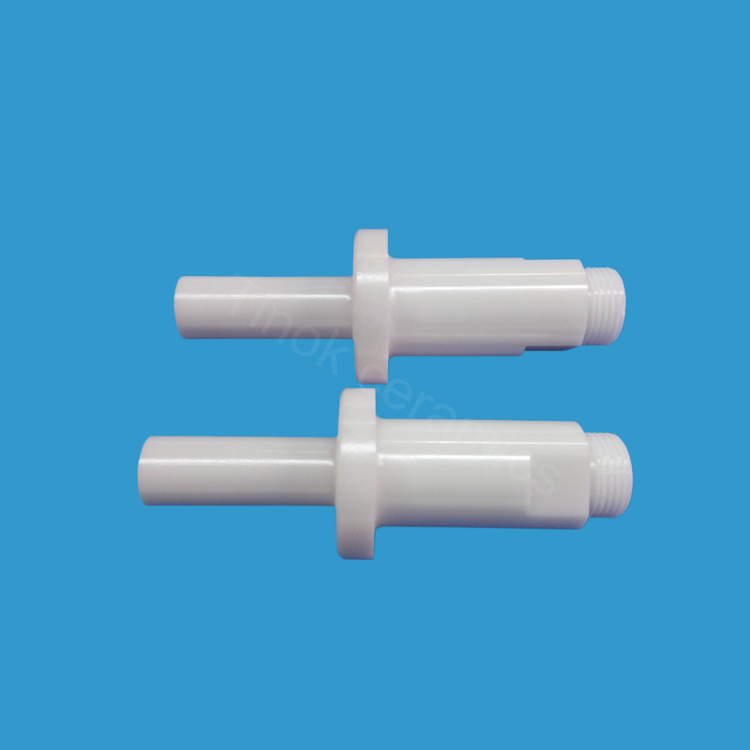

ceramic pins

Ceramic pin high hardness wear heat corrosion resistance ceramic dowel guide position pins

Ceramic positioning pin is a kind of precision positioning device, mainly used in precision machine tool, fixture, CNC machining center and so on. It has the advantages of high hardness, wear resistance, heat resistance, corrosion resistance, insulation, etc., and is widely used in high-precision industrial equipment.

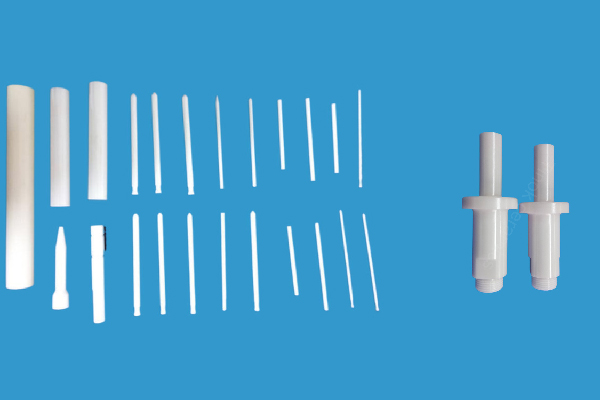

Ceramic positioning pins are available in a wide range of sizes, from 1mm to 100mm. In particular, zirconia ceramic needles and ceramic dowel pins can be adjusted in the size range of 1-100mm

Ceramic positioning pins are divided into two types, respectively, alumina ceramic positioning pins and zirconia ceramic positioning pins. Alumina ceramic positioning pin has the advantages of high hardness, good wear resistance, light weight, etc. The zirconia ceramic positioning pin has the advantages of abrasion resistance, high temperature resistance, chemical corrosion resistance, magnetic resistance and so on.

Ceramic dowel specifications

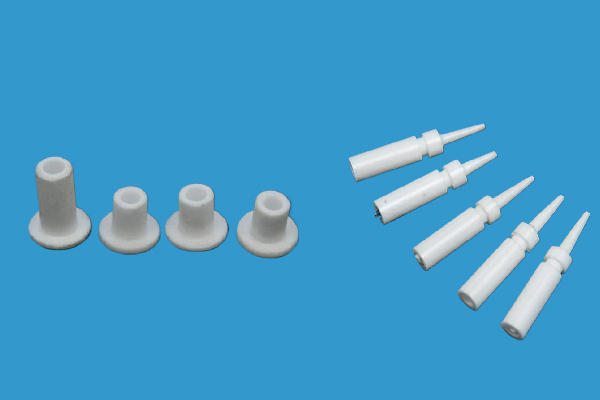

The specifications of ceramic positioning pin mainly include size, shape, material and so on. Among them, the size is to specify the length of the pin, diameter and other dimensional parameters; The shape includes the head shape and tail shape of the positioning pin; The material mainly includes alumina ceramics, zirconia ceramics, silicon nitride ceramics and other materials.

Common ceramic dowel specifications are as follows:

1. Size: The diameter range is 1mm ~ 10mm, the length can be customized according to needs.

2. Shape: divided into cylindrical, conical, spherical, rod and other shapes.

3. Material: mainly alumina ceramics, silicon nitride ceramics and so on.

Common FAQ of ceramic dowel

1. How to choose the suitable ceramic dowel specifications?

The selection of ceramic positioning pin specifications should be selected according to the specific needs, mainly including the material of the object to be positioned, positioning accuracy, positioning force and other factors.

2. How to use ceramic dowel correctly?

When using the positioning pin, pay attention to its correct installation and fixing to ensure its firm positioning of the object, and avoid collision and friction during use, so as not to affect its service life.

3. How to maintain ceramic dowel?

When using and maintaining the positioning pin, it is necessary to do regular cleaning, dust removal and other work to keep its surface clean, and to avoid excessive collision and excessive friction during use.

Some of our ceramic pins on display

ceramic welding pin

Ceramic welding pin high wear resistance and strength welding pin

ceramic centering pin

Ceramic centering pin wear resistant alumina zirconia ceramic pins

ceramic locating pin

Ceramic locating pin high hardness ceramic location dowel pin zro2 ceramic pin

ceramic dowel pin

Ceramic dowel pin custom heat resistant high strength zirconia ceramic pins

ceramic position pin

Ceramic position pin wear resistant strong antioxidant ability zirconia ceramic pin

ceramic guide pin

Ceramic guide pin alumina zirconia high hardness high wear resistance ceramic pins

Advantages of ceramic dowel

- 1. High temperature stability: ceramic positioning pin has excellent high temperature stability, can maintain stable performance in high temperature environment, not easy to deformation.

- 2. Wear resistance: ceramic positioning pin has high hardness and good wear resistance, which can improve the service life of positioning pin.

- 3. Oxidation resistance: The ceramic positioning pin has good oxidation resistance in the air and is not easy to be oxidized, which can ensure the long-term stability of the positioning pin.

- 4. Excellent electrical performance: ceramic positioning pins have good electrical insulation properties and can be used to make various electrical components.

- 5. environmental protection and pollution-free: ceramic is an environmentally friendly material, the preparation process does not produce harmful substances, friendly to the environment.

Application of ceramic pins

- 1. Mechanical manufacturing field: ceramic positioning pins have good wear resistance and high strength, and can be used to make various mechanical parts, such as machine tool guide rails, shaft sleeves, etc.

- 2. Electrical field: Ceramic positioning pins have good electrical insulation and high temperature resistance, and can be used to make high temperature insulators, porcelain bushings and other electrical components.

- 3. Precision instrument field: ceramic positioning pin has high precision and high stability, and can be used to make parts of precision instruments.

- 4. Thermal field: Ceramic positioning pin has excellent high temperature resistance, can be used to make thermocouple casing, high temperature furnace and other thermal equipment.

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.