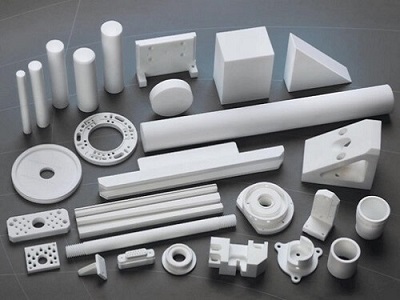

ceramic rod

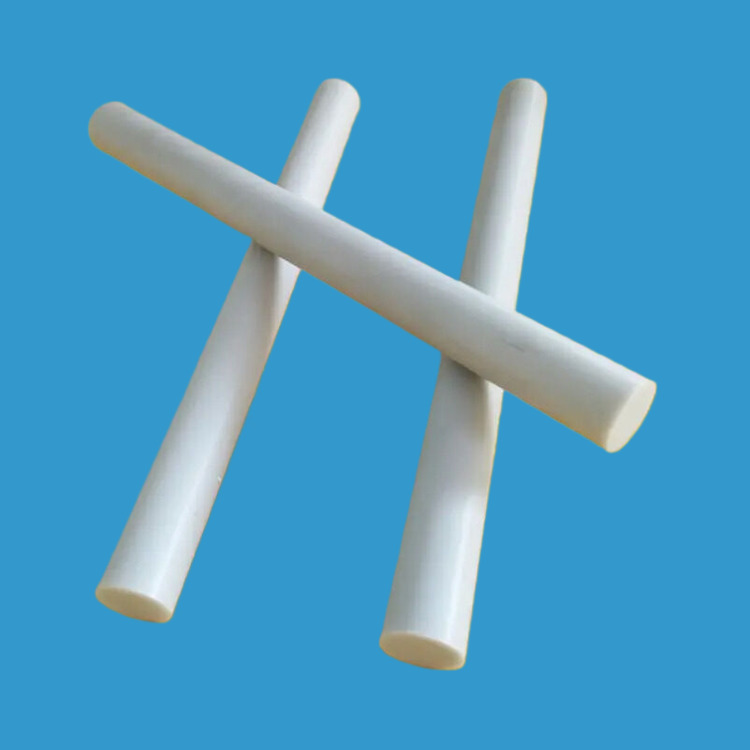

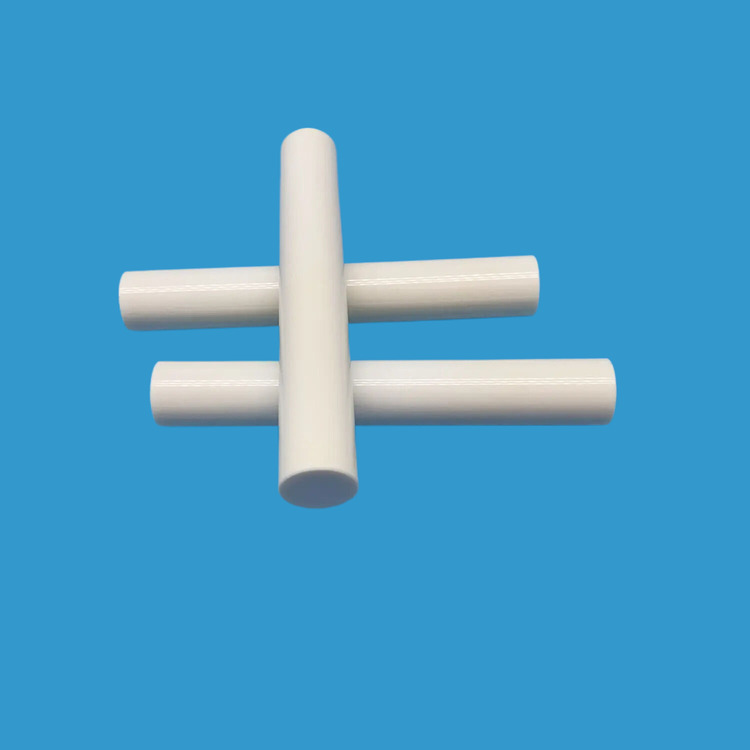

Zirconia ceramic rod wear resistant high hardness zirconium oxide ceramic rod

More details

Alumina ceramic rod high purity 95 to 99% al2o3 alumina ceramic solid rod

More details

Alumina ceramic insulator rod high mechanical strength good high voltage ceramic rod

More details

Wear resistance ceramic rod hardness and fracture toughness al2o3 alumina zro2 zirconia ceramic rod

More details

Machinable ceramic rod alumina zirconia ceramic rod

More details

Ceramic threaded rod high strength alumina zirconia thread ceramic rods

More details

high temperature heat resistance ceramic rods and bars

More detailsContact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.