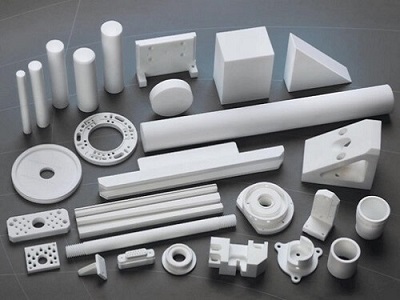

semiconductor ceramic parts

Custom semiconductor ceramic plate vacuum chucks semiconductor vacuum 99% alumina ceramic plate

More details

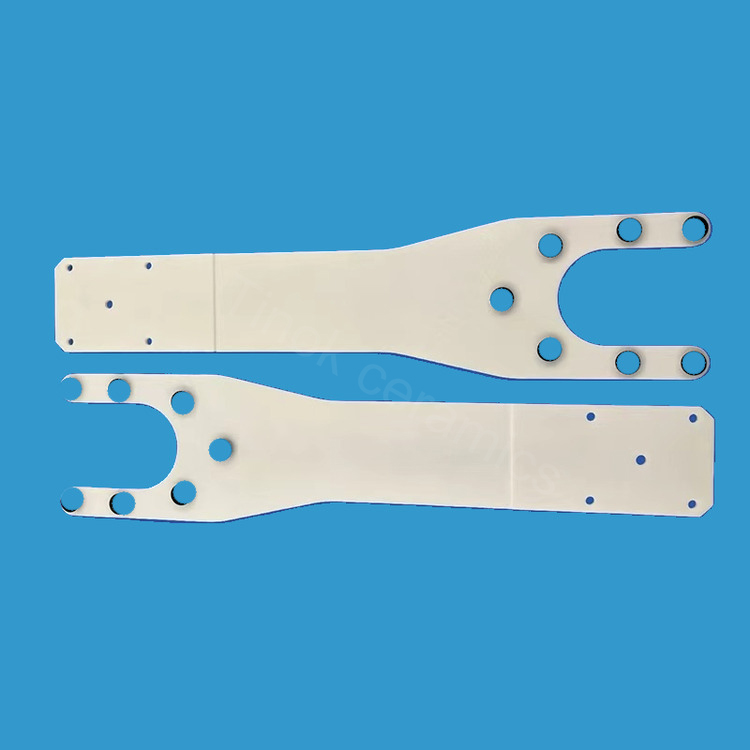

Semiconductor ceramic ceramic wafer handling al2o3 alumina ceramic semiconductor wafer arm end effector

More details

Custom semiconductor ceramic end effector high purity al2o3 alumina ceramic arm hand for semiconductor machine

More details

Semiconductor ceramic ring high purity al2o3 alumina ceramic seal rings in semiconductor equipment

More details

Semiconductor ceramic wafer plate alumina ceramic disk

More detailsContact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.