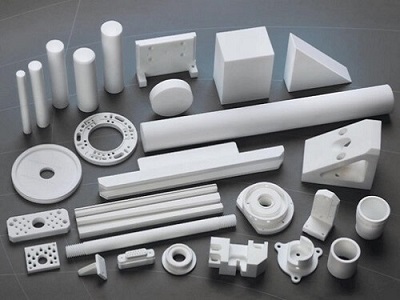

precision ceramic parts

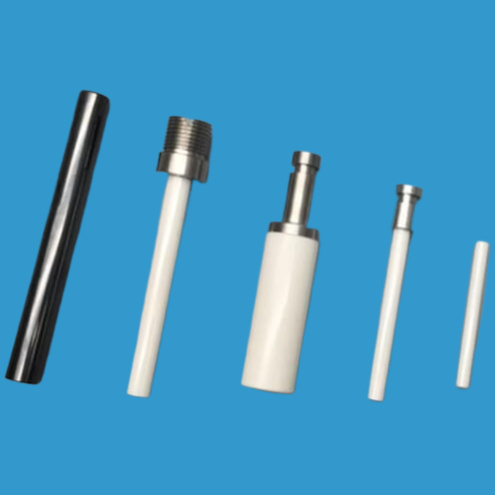

Ceramic plunger rod high precision polishing ceramic piston tubes

More details

Water jet ceramic plunger high polished wearable waterjet parts ceramic plunger rod

More details

General pump ceramic plunger pump ceramic part plunger piston rod tubes

More details

Ceramic plunger rod high precision polishing Al2O3 and ZrO2 ceramic plunger rods

More details

Ceramic piston rod Al2O3 alumina ZrO2 zirconia ceramic piston rod

More details

Alumina ceramic plunger low thermal expansion Al2O3 Aluminium oxide ceramic plunger

More details

Zirconia ceramic plunger high hardness corrosion resistance ZrO2ceramic plunger

More details

Metalization ceramic tube high mechanical strength and bonding strength ceramic tubes

More details

Customized alumina ceramic tube high purity al2o3 machinable aluminum oxide ceramic tubes

More details

Industrial ceramic tube different types sizes of alumina zirconia ceramic tubes

More detailsContact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.