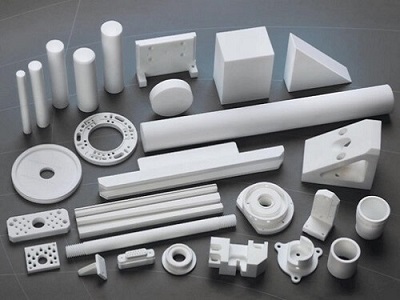

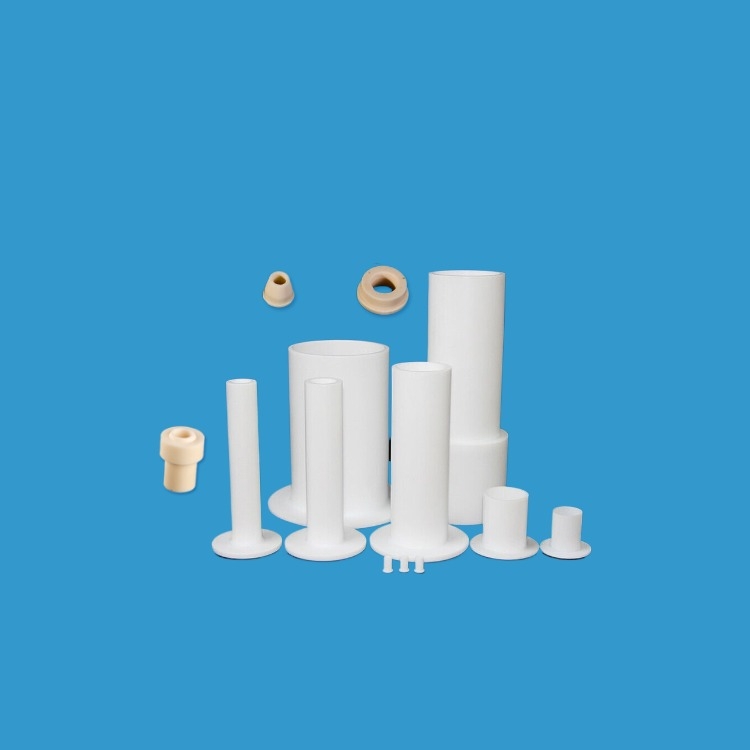

precision ceramic parts

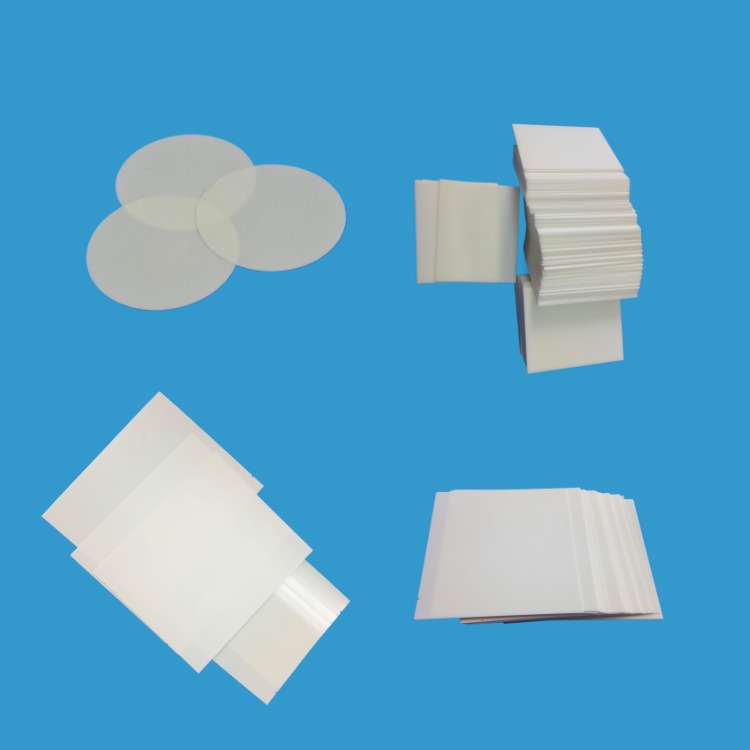

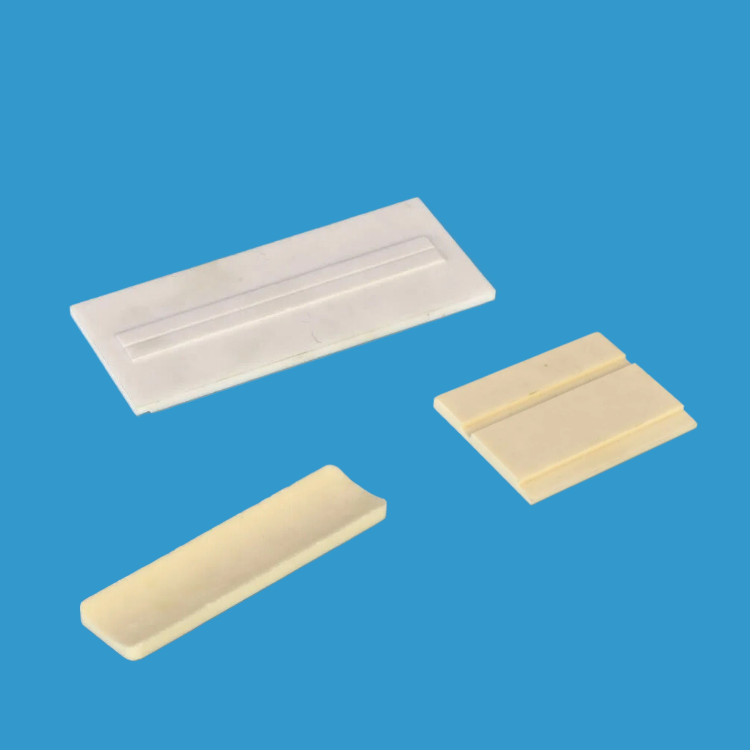

Alumina ceramic plate High Mechanical Strength Al2O3 99.7 99.5 99.9 purity alumina ceramic plate

More details

Alumina ceramic sheet 95% 99% al2o3 high purity alumina sheet ceramic plate parts

More details

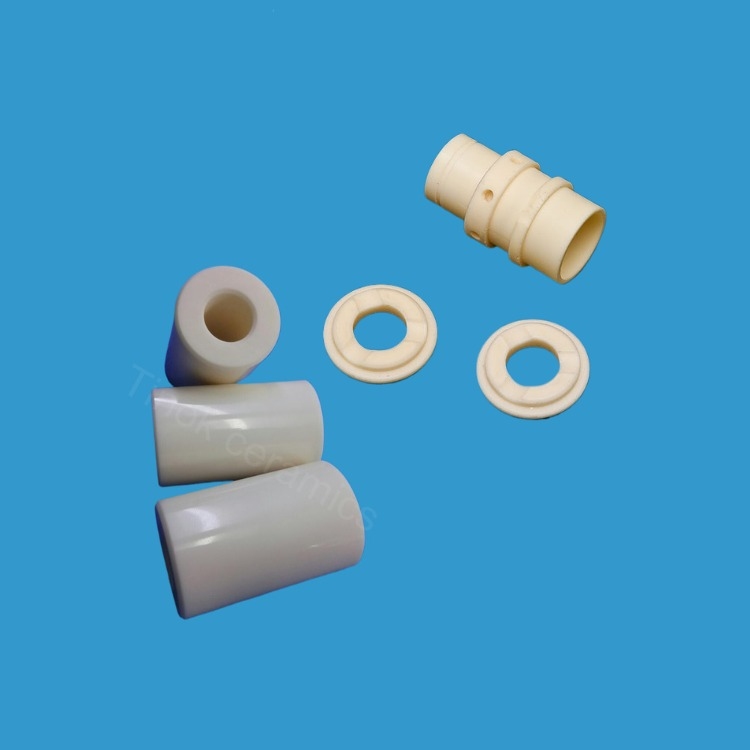

Zirconia ceramic bushing High strength high hardness and wear resistance Zro2 bushings

More details

Sic ceramic bushing high precision wear resistant silicon carbide ceramic bushing

More details

Ceramic pump bushings high hardness corrosion wear resistance zirconia alumina ceramic bushing

More details

Threaded ceramic bushings high strength high precision surface smooth threaded ceramic tube bushing

More details

Ceramic linear bushing zirconia alumina ceramic liner sleeves

More details

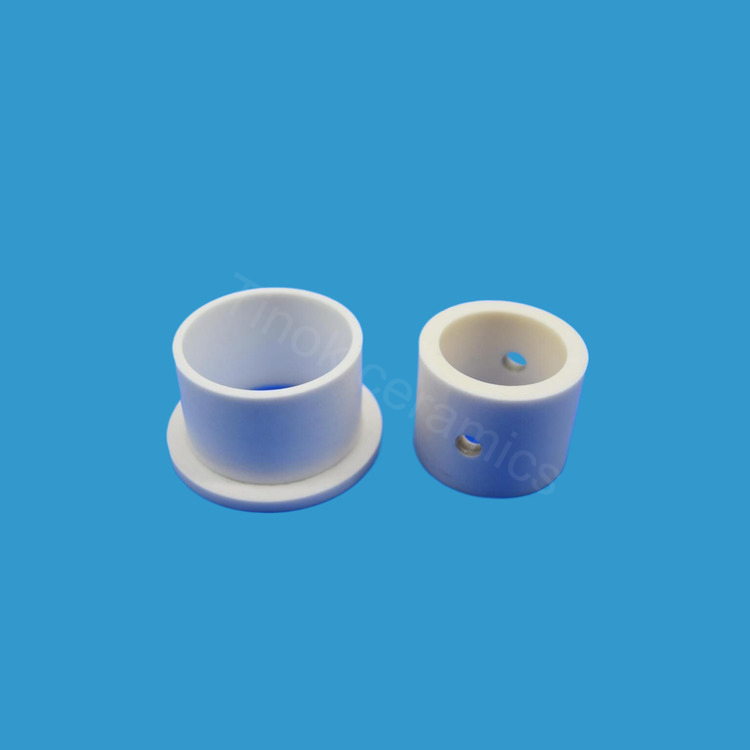

Ceramic beaded bushing high strength ceramic shoulder bushings with wear and friction resistance

More details

Ceramic bushing insulators low thermal conductivity alumina ceramic insulators

More details

Ceramic guide bushing wear resistance ZrO2 or Al2O3 ceramic sleeve bushing

More detailsContact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.