ceramic bushing

Ceramic bushing is a kind of industrial ceramic products, ceramic bushing is mainly used to protect the surface of equipment and mechanical parts, to improve its wear resistance and service life.

Ceramic bushing material

Ceramic bushings are usually made of special ceramic materials such as high-purity alumina, zirconia and silicon carbide. These ceramic materials have high hardness, low density, good wear resistance, strong chemical stability, and have good insulation properties and high temperature stability. Compared to traditional metal bushings, ceramic bushings can provide better sliding effect and longer service life.

Production technology

Ceramic bushing is made through multiple processes, generally including raw material ratio, powder, molding, drying, sintering, precision processing and other processes.

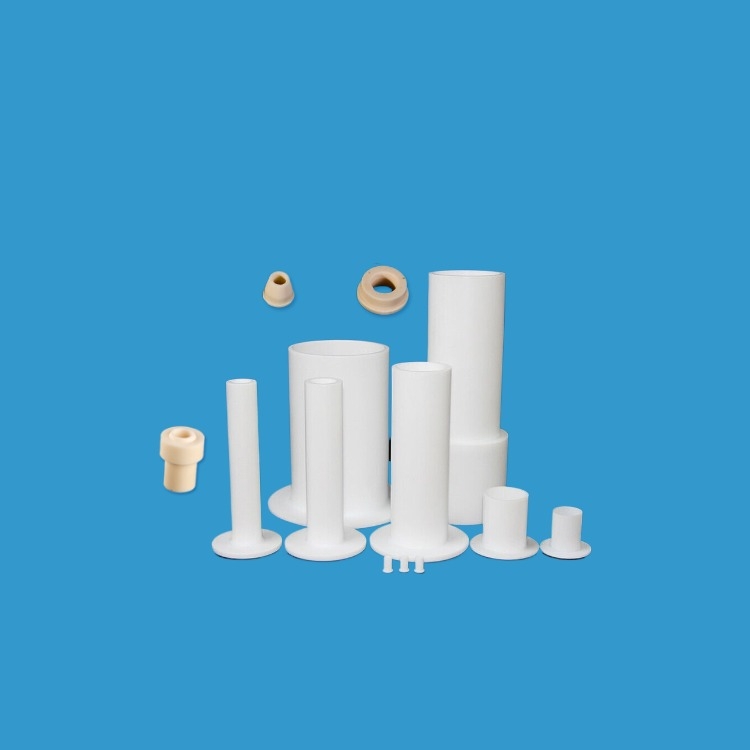

Type of ceramic bushing

Ceramic bushing series

Bushing Bearings; Flanged Bushings...

Ceramic sleeves series

Shaft Sleeve; Sleeve Bearing...

Ceramic lining series

Sleeve Liner...ceramic pins series

Size parameters of ceramic bushing

The size of the ceramic bushing can be customized according to the specific needs, its wide range of sizes, including but not limited to:

Ceramic Sleeve Bushing sizes:

·OD Tolerance: +0.027/+ 0.019mm

·ID Tolerance: +0.002/+0.008mm

·ID sizes range from 3/16” to 3”

The minimum inner diameter can reach 2.0mm, can even reach 1.0mm for non-standard parts.

The maximum outer diameter can reach 230mm.

In addition, ceramic bushing is also a variety of materials, including but not limited to alumina, silicon nitride, zirconia, these materials have good high temperature resistance, corrosion resistance and other characteristics, is widely used in various industrial fields.

Machining parameter

Ceramic bushing machining mutual position accuracy: The position accuracy requirements of ceramic bushing parts are mainly determined by the position and function of ceramic bushing in the machine. Generally, the coaxiality requirements of the shaft journal of the assembly transmission part and the supporting shaft journal should be ensured, otherwise the transmission accuracy of the transmission part (gear, etc.) will be affected and noise will be generated. For ordinary precision ceramic bushing, the radial runout from the shaft section to the supporting journal is generally 0.01-0.03mm, and the high-precision shaft (such as the spindle) is usually 0.001-0.005mm.

How to choose the right bushing for you

1. Select the appropriate type of bushing according to the working conditions and environment of the mechanical equipment;

2. Select the appropriate manufacturer according to the material and quality requirements of the bushing;

3. Select the appropriate type and specification according to the requirements of bushing size and shape.

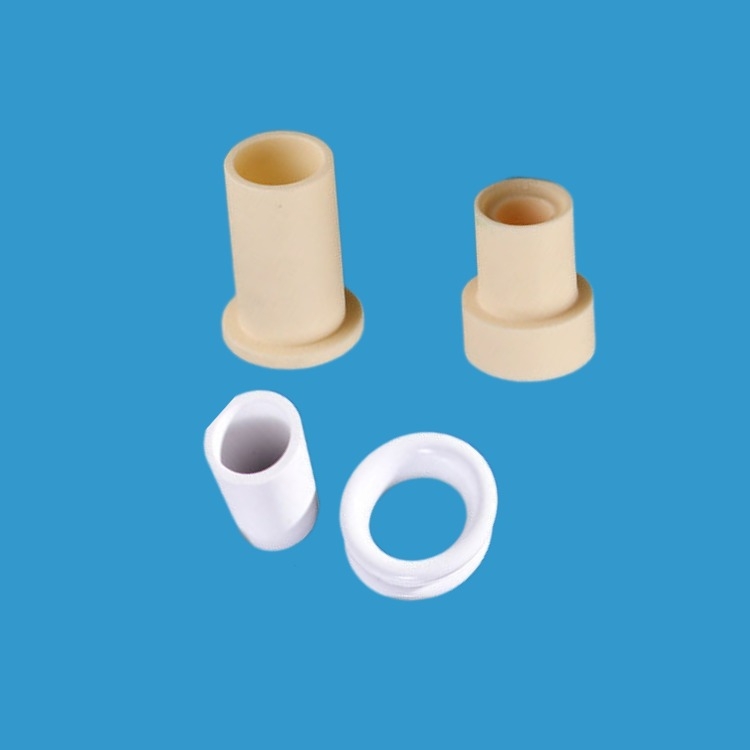

Some of our ceramic bushing on display

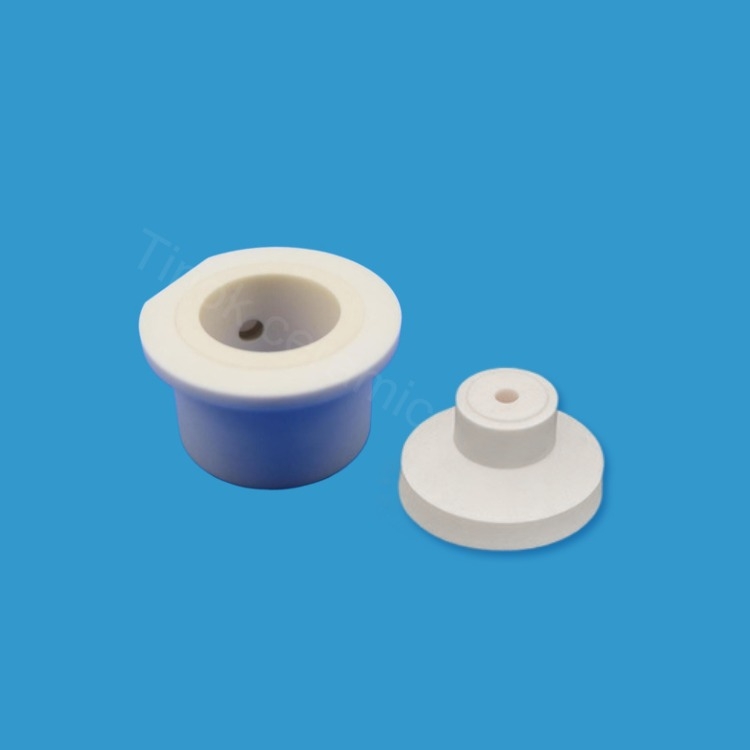

ceramic shoulder bushing

Ceramic shoulder bushing hardness strength wear resistant ceramic flanged bushings

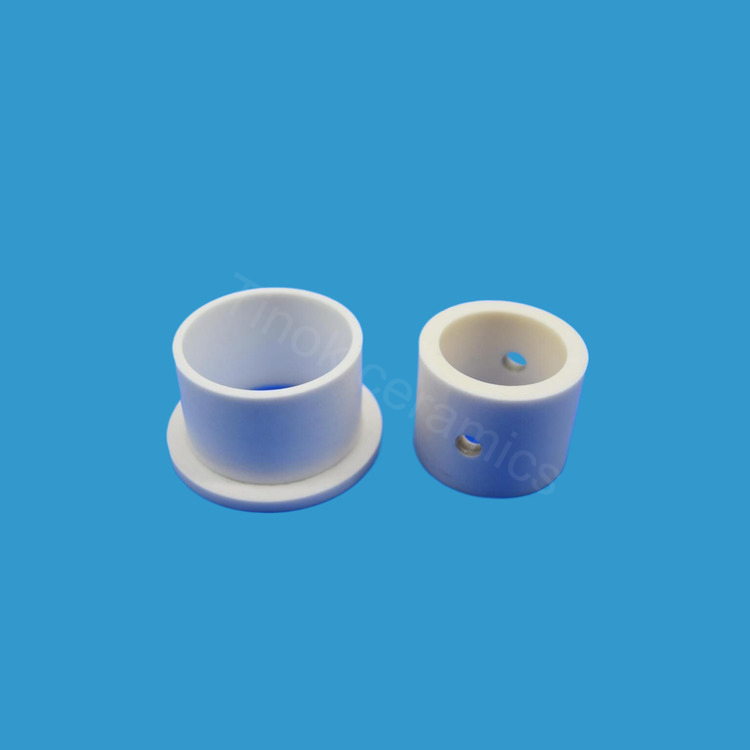

high temperature ceramic bushings

High temperature ceramic bushing high heat resistant ceramic sleeve bushings

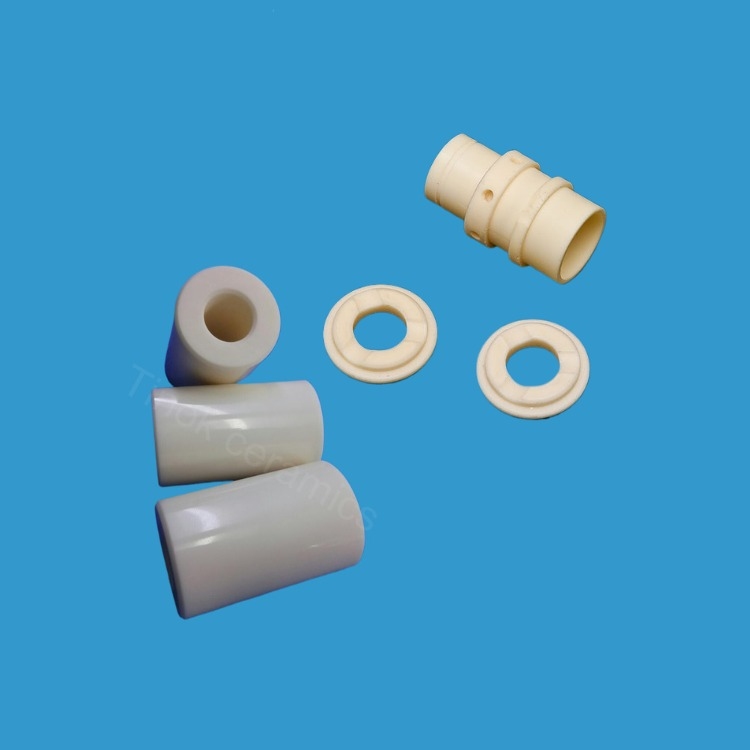

ceramic guide bushing

Ceramic guide bushing wear resistance ZrO2 or Al2O3 ceramic sleeve bushing

ceramic bushing insulator

Ceramic bushing insulators low thermal conductivity alumina ceramic insulators

ceramic headed bushing

Ceramic beaded bushing high strength ceramic shoulder bushings with wear and friction resistance

ceramic linear bushing

Ceramic linear bushing zirconia alumina ceramic liner sleeves

threaded ceramic bushing

Threaded ceramic bushings high strength high precision surface smooth threaded ceramic tube bushing

ceramic pump bushings

Ceramic pump bushings high hardness corrosion wear resistance zirconia alumina ceramic bushing

alumina ceramic bushing

Alumina ceramic bushing high purity 95 to 99.7 al2o3 aluminum oxide ceramic bushing

sic ceramic bushing

Sic ceramic bushing high precision wear resistant silicon carbide ceramic bushing

zirconia ceramic bushing

Zirconia ceramic bushing High strength high hardness and wear resistance Zro2 bushings

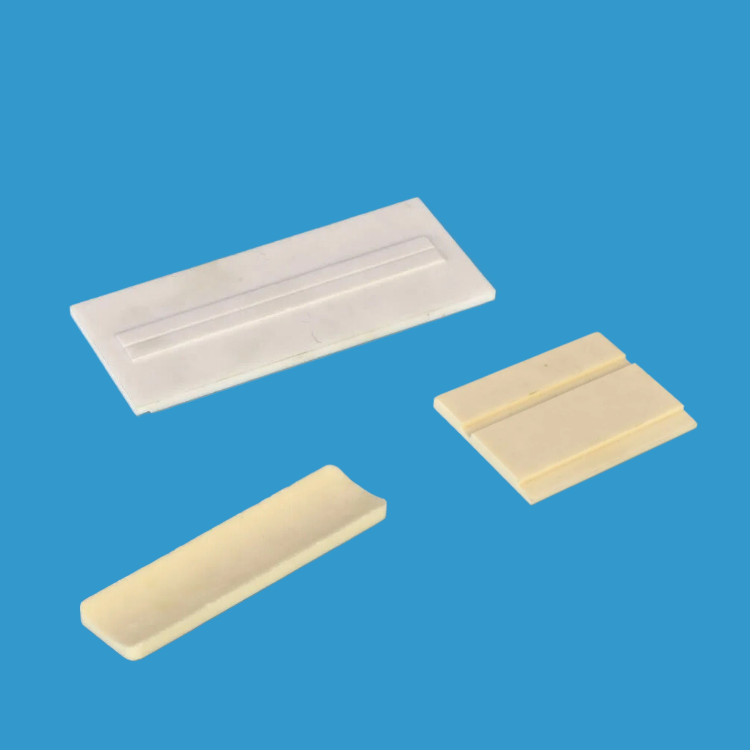

alumina ceramic sheet

Alumina ceramic sheet 95% 99% al2o3 high purity alumina sheet ceramic plate parts

Ceramic bushing characteristics

- 1. Excellent wear resistance: Ceramic bushing has good wear resistance, that is, it is not easy to wear during use, and can effectively improve the service life of the material.

- 2. Good high temperature resistance:ceramic bushing performs very well at high temperatures and can still maintain good mechanical properties and chemical stability at high temperatures.

- 3. Excellent corrosion resistance:ceramic bushing in chemical corrosion environment has good corrosion resistance, can withstand a variety of harmful substances erosion, so as to ensure the long-term safe operation of the equipment.

- 4. Good antioxidant properties:ceramic bushing has good oxidation resistance in high temperature flowing medium, and can effectively resist the influence of fluid oxidation decomposition and solid particle sintering.

Application of ceramic bushing

- 1. Iron and steel metallurgy industry

- 2. Power industry: In the power industry, ceramic bushings are usually used in the water wall and superheater of thermal power station boilers, which can maintain safe operation for a long time, reduce energy loss, and improve power generation efficiency.

- 3. Chemical industry: In the chemical industry, ceramic bushings are usually used for the production of corrosive substances such as strong acids and alkali storage tanks and pipelines, which can effectively prevent equipment from being corroded and affecting production.

- 4. High-tech fields such as aviation, aerospace and semiconductors: In high-tech fields such as aviation, aerospace and semiconductors, ceramic bushings can be used to manufacture parts for various high temperature, high pressure and high-precision equipment to ensure high reliability and high performance of equipment.

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.