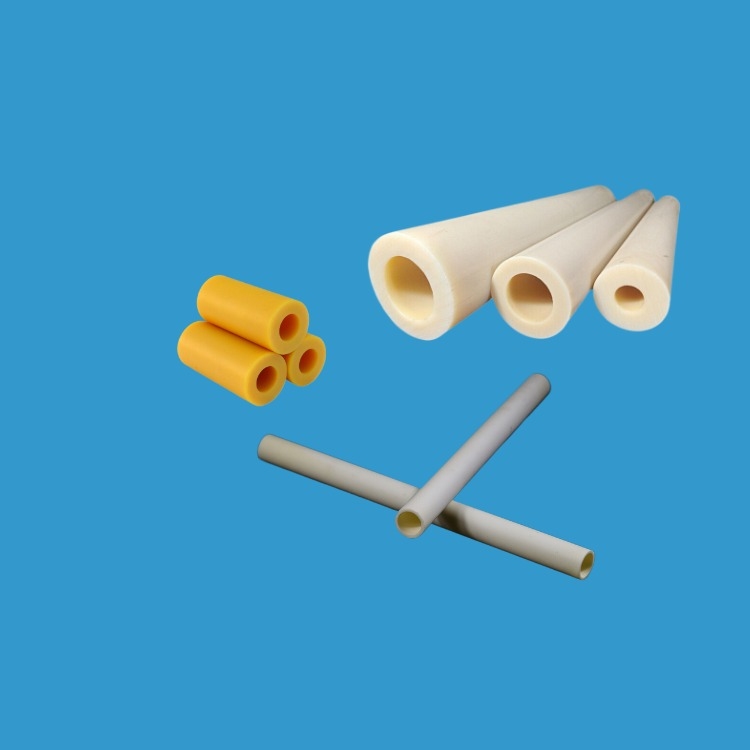

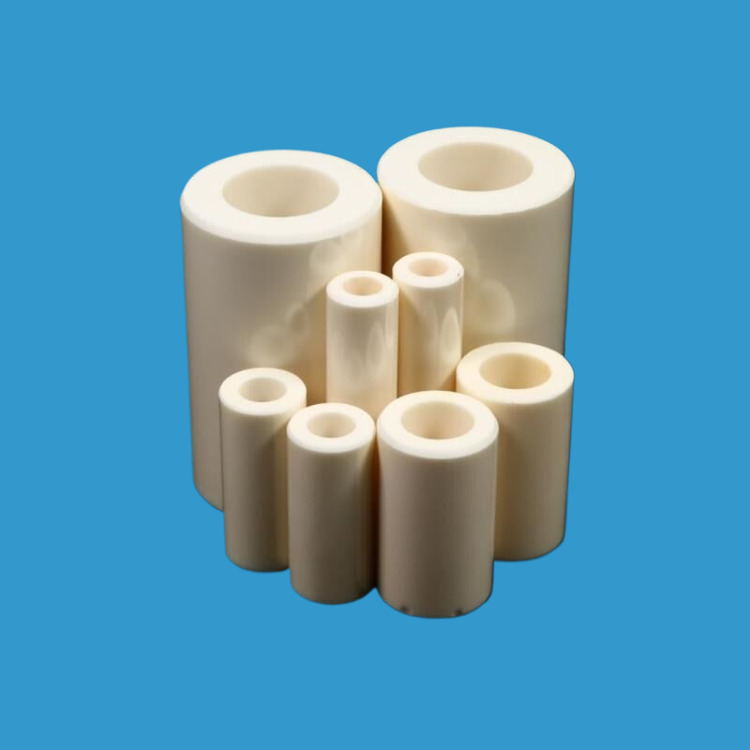

ceramic tube

The parameter size of ceramic tubes varies greatly depending on the application field, material type and manufacturing process. The following are our common parameter categories and typical ranges (we can also customize ceramic tubes with different parameters according to customer needs) :

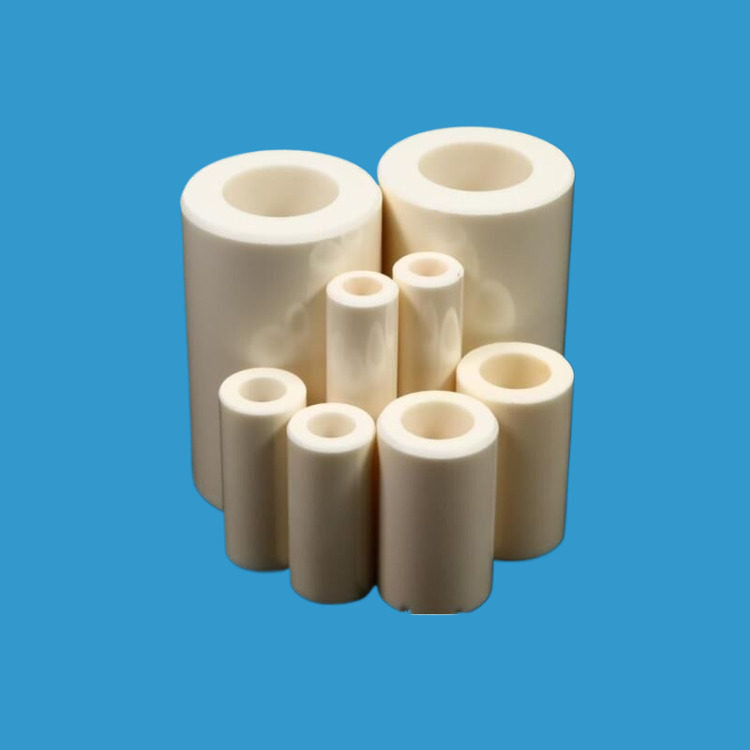

Basic size parameters

- Inside diameter (ID):Usually 1 mm to 500 mm, micro-electronic ceramic tubes may be smaller (e.g. 0.5 mm).

- Outer diameter (OD):Common range 2 mm to 600 mm, depending on wall thickness.

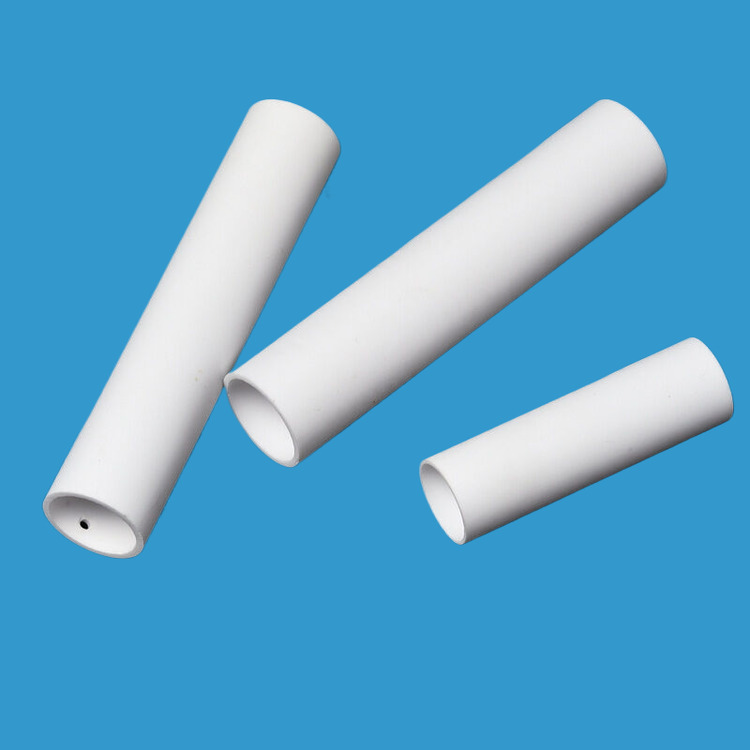

- Length:short tube (10-100 mm), standard tube (100-500 mm), long tube (>500 mm).

- Wall thickness:usually 0.5 mm to 20 mm, high pressure pipe wall is thicker.

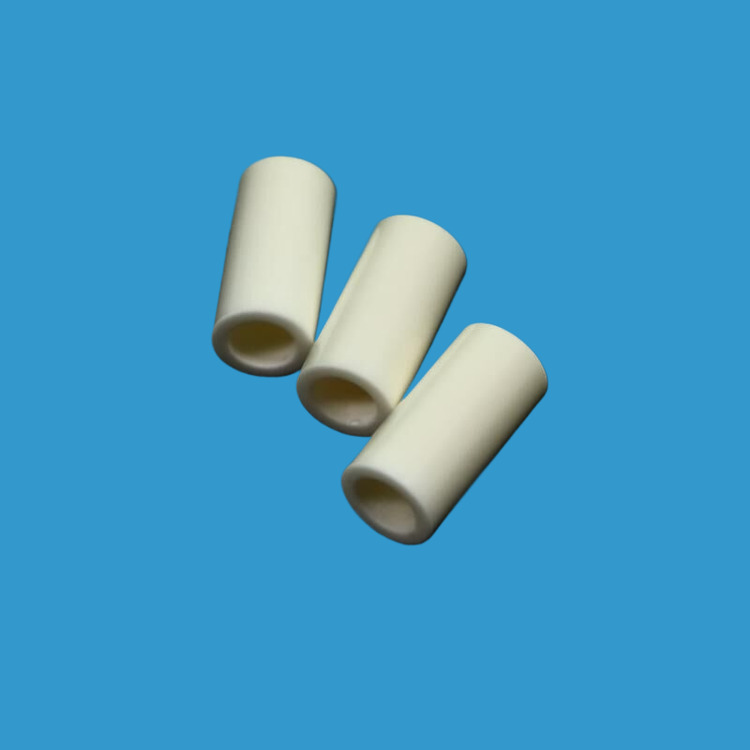

Material characteristic parameters

- Alumina (Al2O3):95% to 99% purity (temperature 1500-1700 °C).

- Zirconia (ZrO2):temperature 2000-2200 °C, high toughness.

- Silicon nitride (Si3N4):Resistance to shock, high mechanical strength.

- Silicon carbide (SiC):good thermal conductivity, corrosion resistance.

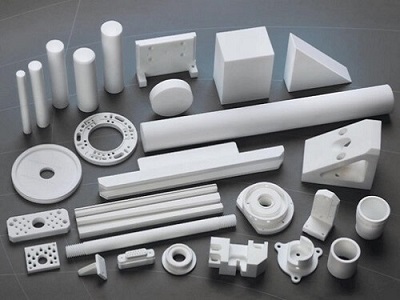

Apply related parameters

- Resistant medium:acid and alkali, molten metal (such as zirconia acid and alkali, silicon carbide aluminum).

- Connection method:flange, threaded joint or adhesive (need to consider thermal expansion matching).

- Surface roughness:Ra 0.1-1.6μm (polishing treatment can reduce fluid resistance).

Selection suggestion

- Electronics/Semiconductors: Focus on insulation, dimensional accuracy (such as aluminum oxide thin-walled tubes).

- Industrial high temperature pipes: preferential temperature resistance, thermal shock resistance (such as zirconia or silicon carbide).

- Medical/Chemical: Select corrosion-resistant, biocompatible materials (such as high-purity alumina).

Contact Form

Tips:If you have any questions, please contact us, we will get back to you within 1 hour.